Production method of green tea

A production method and green tea technology, applied in the direction of tea substitutes and the like, can solve the problems of limited suitable population, low nutritional value and quality of green tea, and achieve the effects of mellow and fresh taste, stable quality and rich nutrition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

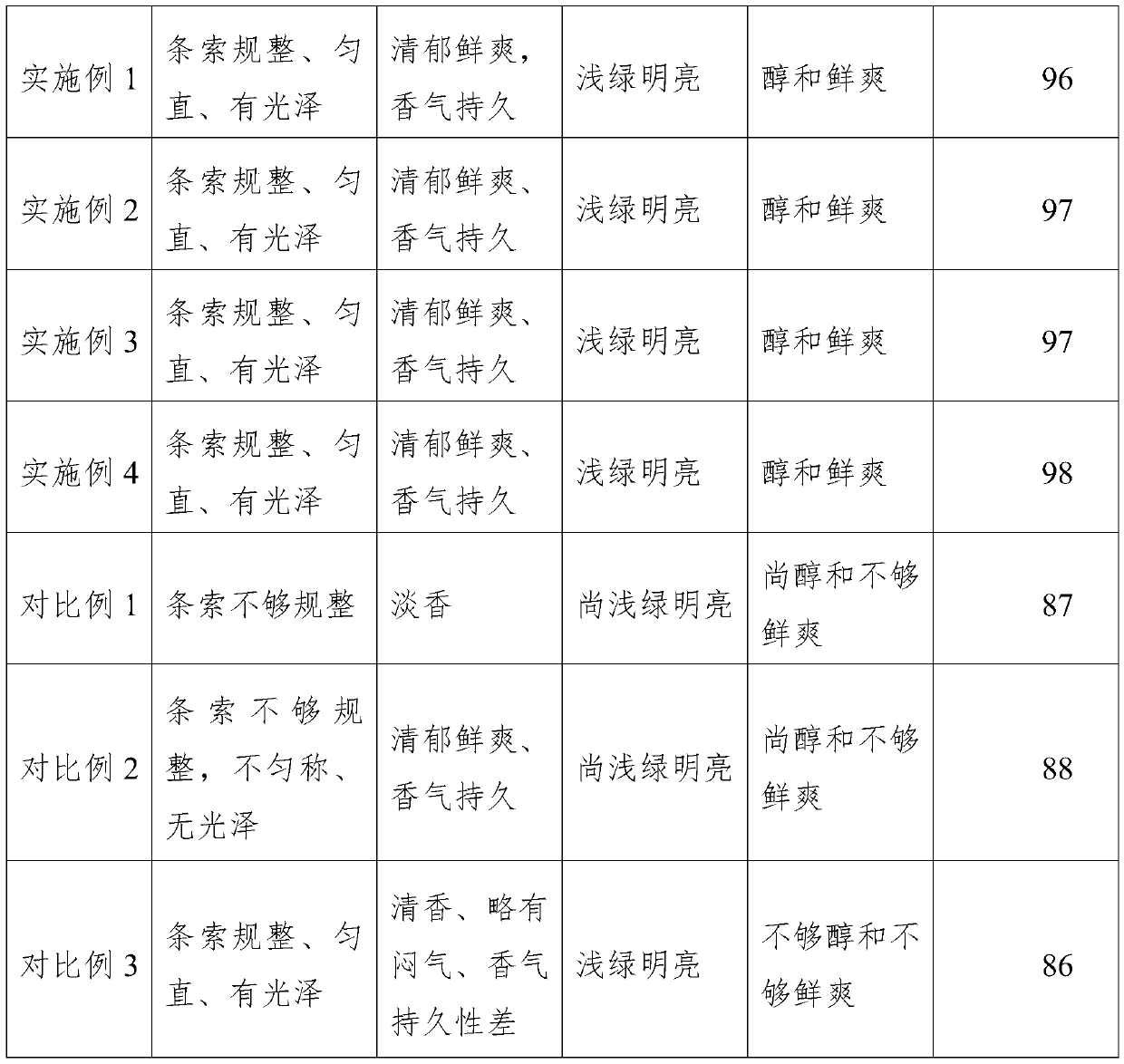

Examples

Embodiment 1

[0029] The present embodiment provides a kind of preparation method of green tea, comprises the following steps:

[0030] (1) picking barley blades that are in the later stage of barley tillering;

[0031] (2) cleaning barley leaves, removing impurities, grading and drying, and then drying;

[0032] (3) the dried barley blades are cut into loose leaf segments;

[0033] (4) Use wood fire to preheat the greening machine. When the temperature of the pot surface of the greening machine is 120°C, put the loose leaf segment in the greening machine for greening. The speed of the greening machine is 3r / min, and the greening time is 25min. The water content is 70%, take it out of the pot and cool down for 5 minutes;

[0034] (5) Put the loose leaf segment in the green fixer for secondary fixation, set the temperature of the pot surface of the fixer to 160°C, the speed of the fixer at 3r / min, and the fixation time for 30min until the water content of the loose leaf segment is 50, pot...

Embodiment 2

[0041] The present embodiment provides a kind of preparation method of green tea, comprises the following steps:

[0042] (1) picking the barley blades that are in the barley tillering stage to the jointing stage;

[0043] (2) cleaning barley leaves, removing impurities, grading and drying, and then drying;

[0044] (3) the dried barley blades are cut into loose leaf segments;

[0045] (4) Preheat the green fixing machine until the temperature of the pot surface of the green fixing machine is 150°C, put the loose leaf segment in the green fixing machine for finishing, the speed of the green fixing machine is 5r / min, the fixing time is 30min, until the water content of the loose leaves is 75%, take out of the pan and cool down for 10 minutes;

[0046] (5) Put the loose leaf segment in the green fixer for secondary fixation, set the temperature of the pot surface of the fixer to 180°C, the speed of the fixer at 5r / min, the fix time for 40min, until the water content of the loo...

Embodiment 3

[0052] The present embodiment provides a kind of preparation method of green tea, comprises the following steps:

[0053] (1) picking the barley blades that are in the barley tillering stage to the jointing stage;

[0054] (2) cleaning barley leaves, removing impurities, grading and drying, and then drying;

[0055] (3) the dried barley blades are cut into loose leaf segments;

[0056] (4) Preheat the green fixing machine until the temperature of the pot surface of the green fixing machine is 130°C, place the loose leaf segment in the green fixing machine for finishing, the speed of the green fixing machine is 4r / min, the fixing time is 28min, until the water content of the loose leaves is 72%, take out of the pan and cool down for 8 minutes;

[0057](5) Put the loose leaf segment in the green fixer for secondary fixation, set the temperature of the pot surface of the fixer to 170°C, the speed of the fixer at 4r / min, the fix time for 35min, until the water content of the loo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com