Electrostatic dust collector oval tube impulse wave type discharge cathode wire

An electrostatic precipitator and elliptical tube technology, applied in the field of industrial environmental protection and dust removal, can solve problems such as uneven distribution of electric field force, poor dust removal effect, long engineering time, etc., achieve simple connection, reduce construction labor intensity, and low production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

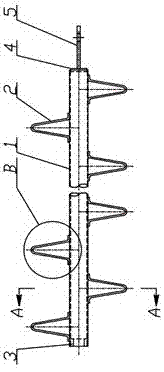

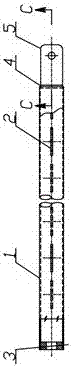

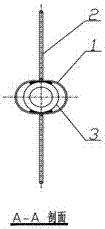

[0020] as attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 and Figure 8 As shown, the technical solution adopts a high-frequency elliptical welded pipe 1 as a rigid metal pipe, and evenly welds φ2mm pulse wave needles 2 with a spacing of 100mm on the wall of the high-frequency elliptical welded pipe 1 and symmetrically interlaced on the long axis of the ellipse.

[0021] The upper end of the high-frequency elliptical welded pipe 1 is thickened with the elliptical piece 4 and welded with the upper hanging piece 5. The elliptical piece 4 is welded on the end of the high-frequency elliptical welded pipe 1. The end faces of sheet 4 are welded together, and the top frame 6 is connected with standard bolts and nuts through angle steel, and the guide ring 3 is welded in the lower end hole of the high-frequency elliptical welded pipe 1, and the guide ring 3 is directly inserted into the bottom frame to guide during installation. Rod 7, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com