Novel heating and pressurizing device for drum vulcanizer

A technology of drum vulcanizer and pressurizing device, which is applied in the application, household appliances, other household appliances, etc., can solve the problems of limited heating method, single pressing method, uneven heating, etc., so as to shorten the vulcanization time and improve the Effect of Vulcanization Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

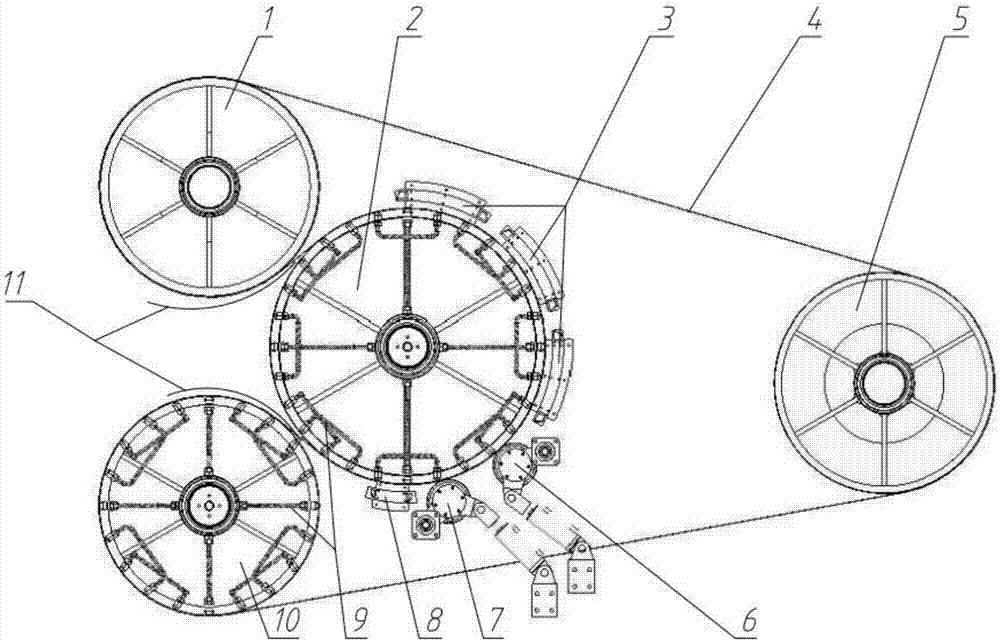

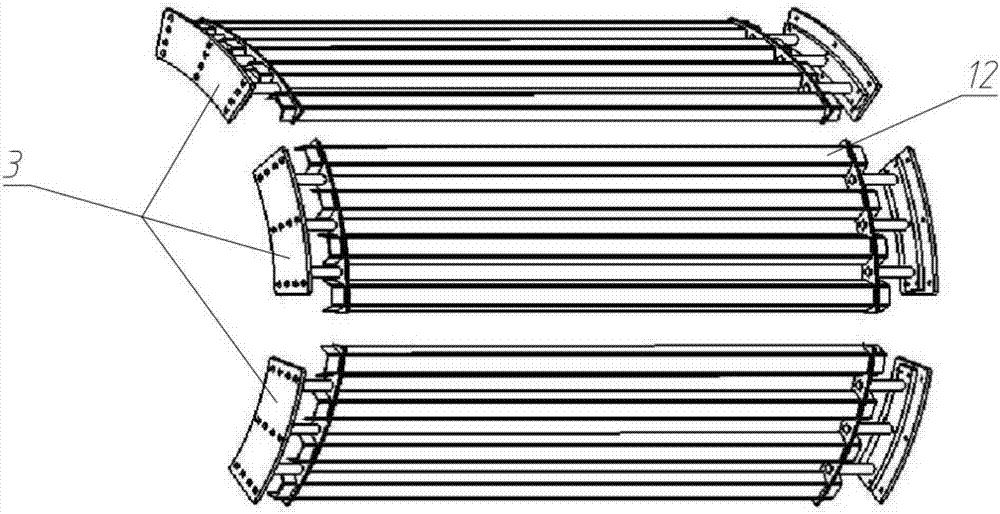

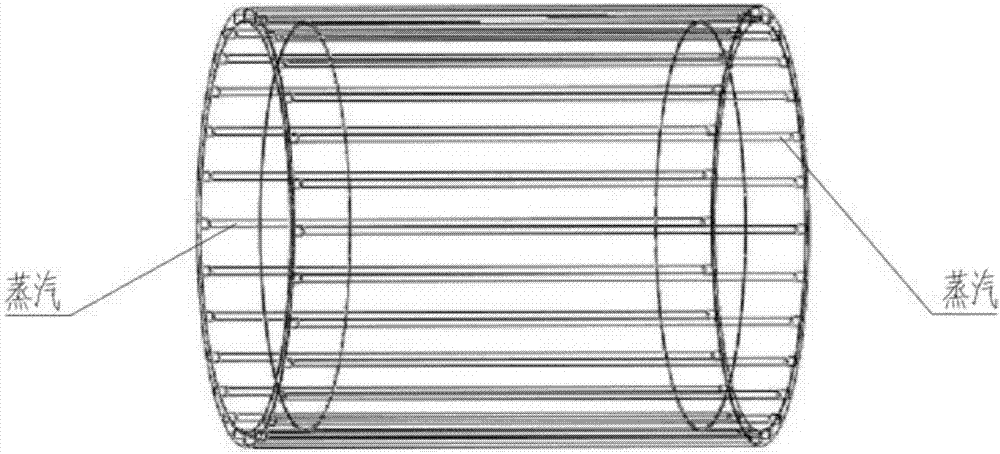

[0021] like figure 1 , 2 , a novel heating and pressurizing device for a drum vulcanizer shown in 3, including a driving roller 1, a vulcanizing drum 2, an electric heating tube group A3, a steel belt 4, a tension roller 5, a first pressure roller 6, a Two pressure rollers 7, electric heating tube group B8, preheating roller 9, connecting water pipe 10, adhesive tape 11, and electric heating tube 12.

[0022] The adhesive tape is preheated by the preheating roller 9 before vulcanization, and the adhesive tape after the preheating enters the vulcanization process through the steel strip 4. Adhesive tape 11 vulcanizes when it enters the wrap angle surface produced by steel belt 4 and vulcanization drum 2 . During the movement of the tape 11 on the entire wrapping surface, the vulcanizing drum 2 and the steel belt 4 provide pressure, while the first pressure roller 6 and the second pressure roller 7 provide auxiliary pressure. Under the joint action of the two, the pressure can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com