Tire steel wire bead fabric pre-compounding machine and implementation method thereof

A compound machine and steel wire technology, applied in tires, other household appliances, household appliances, etc., can solve the problems of high strength and low efficiency, and achieve the effect of improving the service life, perfecting the process, and improving the cracking of the mouth and the wire of the mouth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

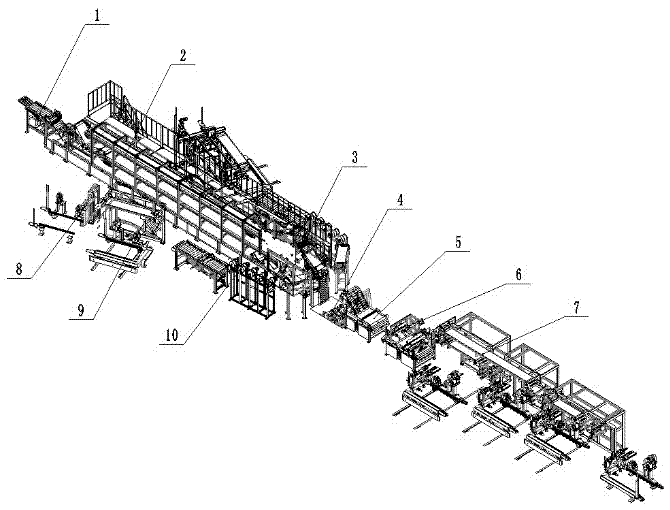

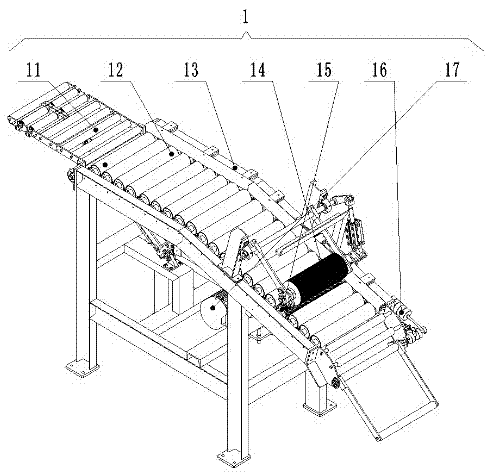

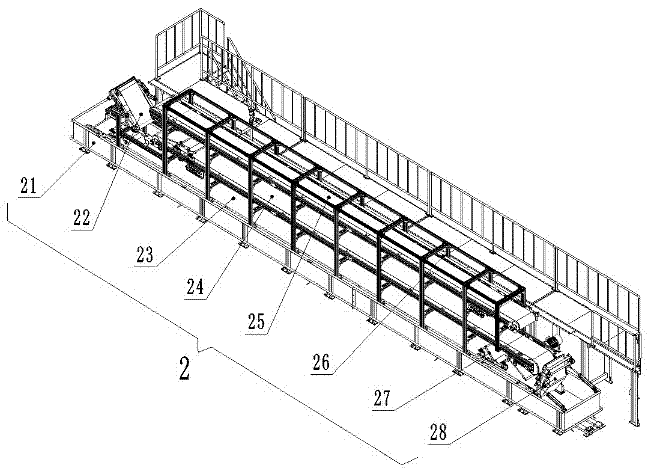

[0029] Such as figure 1 As shown, a pre-compound machine for tire steel wire slit wrapping cloth, which includes a pulling device 1, a cooling water tank device 2, a water removal device 3, a pad rubber storage device 4, a pad rubber laminating device 5, and an end head glue stick Closing device 6, multi-station coiling device 7, release device 8, nylon cloth laminating device 9 and nylon cloth storage device 10; pulling device 1, cooling water tank device 2, dewatering device 3, pad rubber storage device 4. Pad glue fitting device 5, end head glue fitting device 6 and multi-station coiling device 7 are all horizontally arranged side by side on the same horizontal straight line. Pulling device 1 is located at the front end of the whole line, cooling The water tank device 2 is horizontally connected to the rear end of the pull-out device 1, the water removal device 3 is connected to the rear of the cooling water tank device 2, the pad rubber storage device 4 is located behind t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com