Connecting rod of transverse stabilization rod and machining process of ball pin assembly

A technology of horizontal stabilizer bar and processing technology, which is applied to the interconnection system, cantilever mounted on the pivot, suspension, etc., which can solve the problems of low processing production efficiency, large blank machining allowance, and reduced service life of connecting rods , to achieve the effect of increasing processing efficiency, reducing processing cost, and good working properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0030] The present invention will be described in detail below with reference to the accompanying drawings and examples.

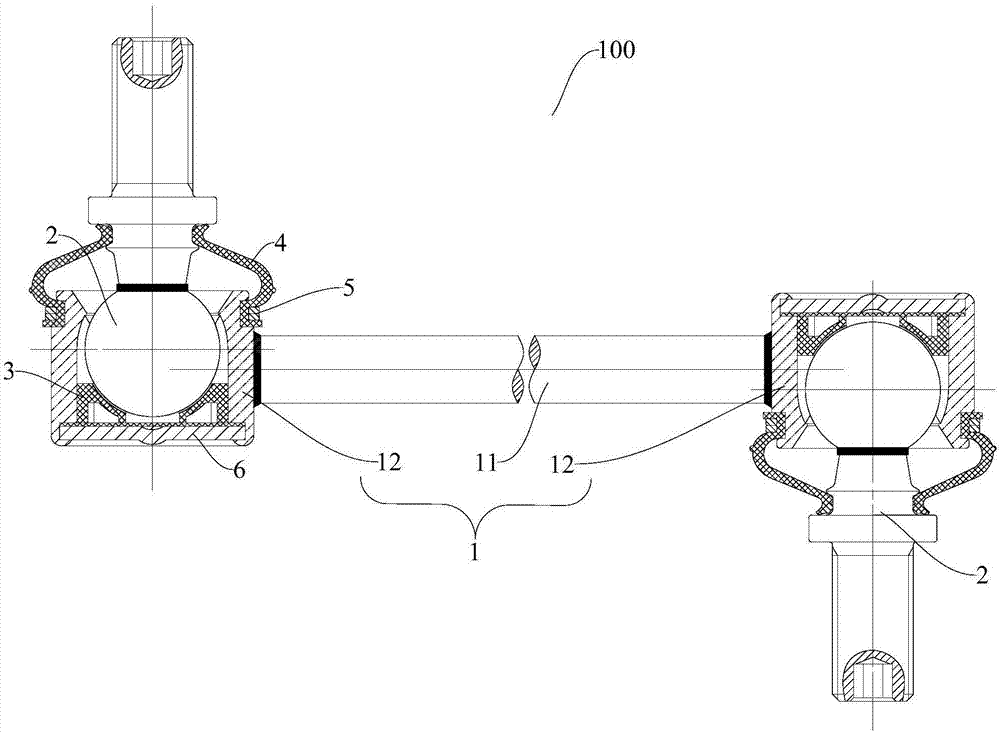

[0031] The connecting rods 100 of the stabilizer bar are used to fix the stabilizer rod on the left and right suspension lower arms or the shock absorber struts, and for four-wheeled vehicles, each vehicle is provided with four connecting rods 100 .

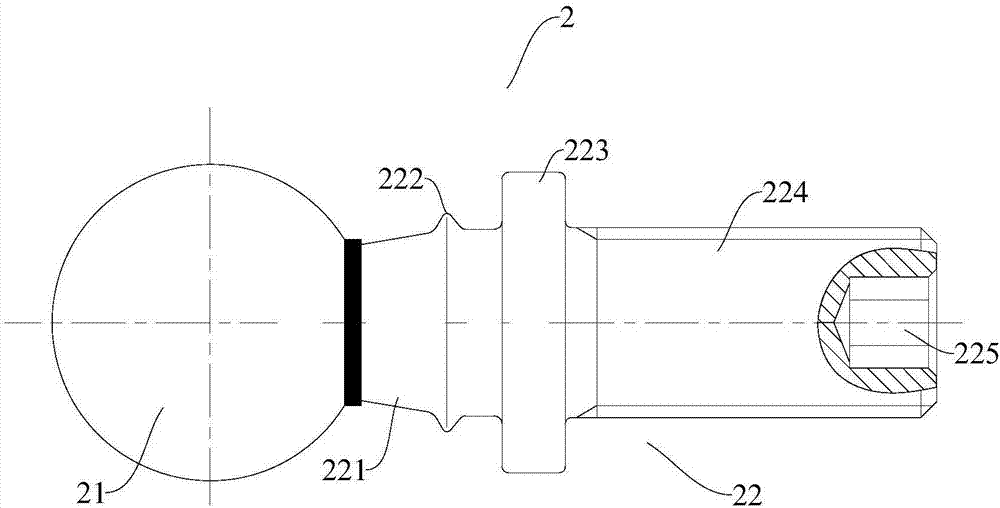

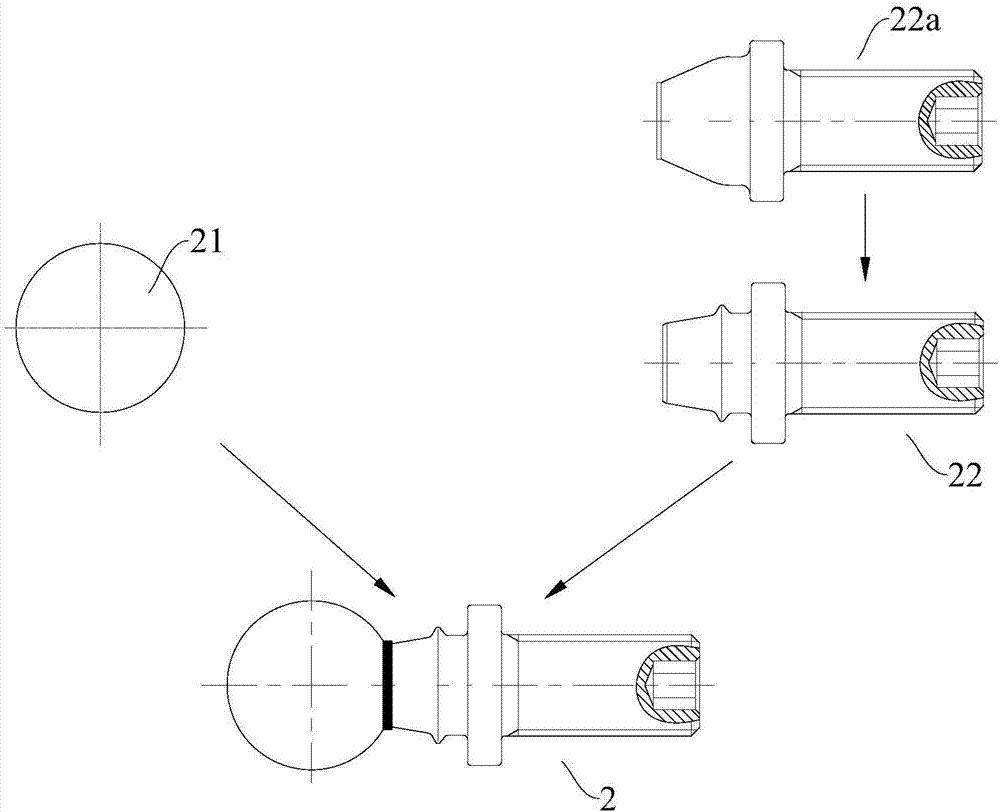

[0032] like Figure 1-Figure 2 As shown, the connecting rod 100 of the stabilizer bar includes a ball pin seat assembly 1 , a bush 3 and a ball pin assembly 2 .

[0033] Wherein, the ball pin seat assembly 1 has an intermediate connecting rod 11 and a ball pin seat 12, and the ball pin seat 12 is fixedly connected with the intermediate connecting rod 11. For example, the ball pin seat 12 can be connected with the intermediate connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com