Chestnut kernel arrangement and placement machine based on three-axis ball screw sliding table and work method of chestnut kernel arrangement and placement machine

A technology of chestnut kernels and sliding table, applied in the direction of single object, packaged food, packaging, etc., can solve the problems of low production efficiency and poor hygiene guarantee, and achieve the effect of improving packaging efficiency, convenient control, fast and accurate positioning and arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

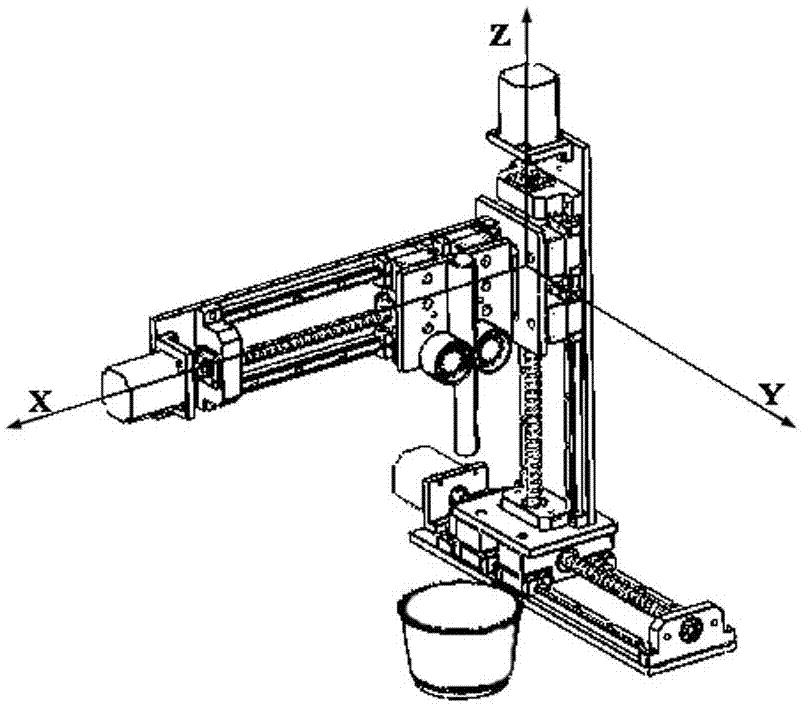

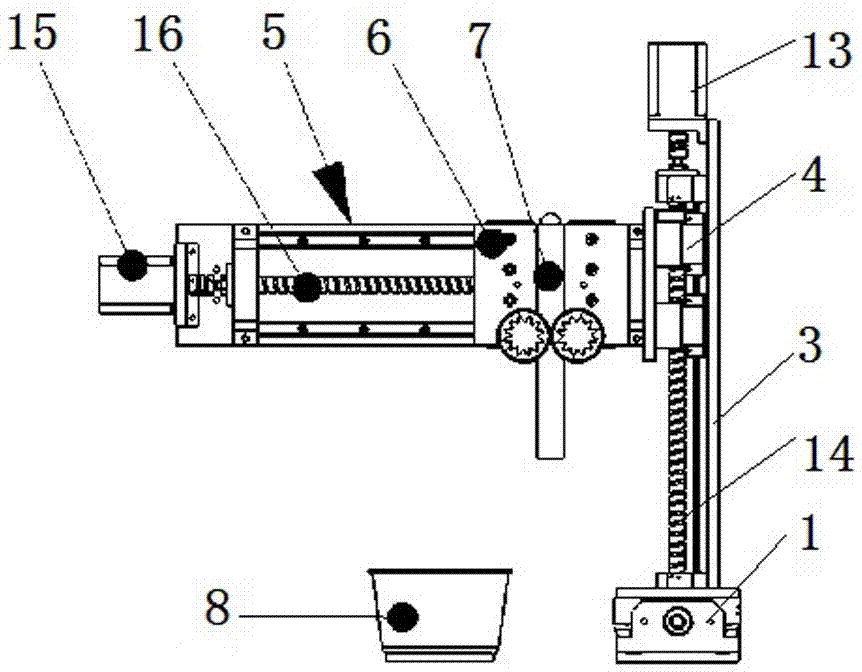

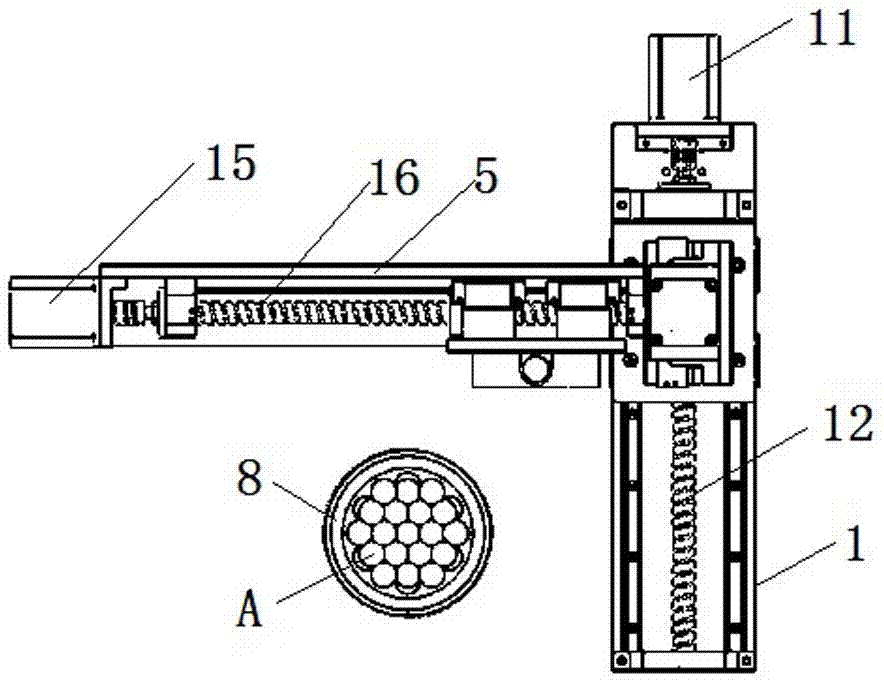

[0026] The present invention is based on the three-axis ball screw sliding table chestnut arrangement machine includes a horizontal machine base 1 and a first horizontal sliding seat 2 arranged on the horizontal machine base 1, on which the first horizontal sliding seat 2 is erected There is a first stand 3, the first stand 3 is provided with a first sliding stand 4 that can move up and down along the first stand 3, and the first slide stand 4 is provided with a second horizontal seat 5 , the second horizontal seat 5 is provided with a horizontally movable slide 6 that can move along the second horizontal seat 5, and the horizontally movable slide 6 is provided with an intermittent blanking mechanism 7, and the intermittent blanking mechanism 7 A packing tank 8 is arranged beside the horizontal support.

[0027] Further, in order to design rationally, the above-mentioned intermittent blanking mechanism 7 includes a central blanking pipeline 9 for containing chestnuts and rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com