Glass horizontal linear conversion table and control method thereof

A conversion table and glass technology, applied in glass production, furnace, electric charge control, etc., can solve the problems of only small size glass, large machine footprint, complex positioning mechanism, etc., to save cost resources, high degree of automation, The effect of high conveying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Below in conjunction with accompanying drawing and embodiment, the present invention is further described:

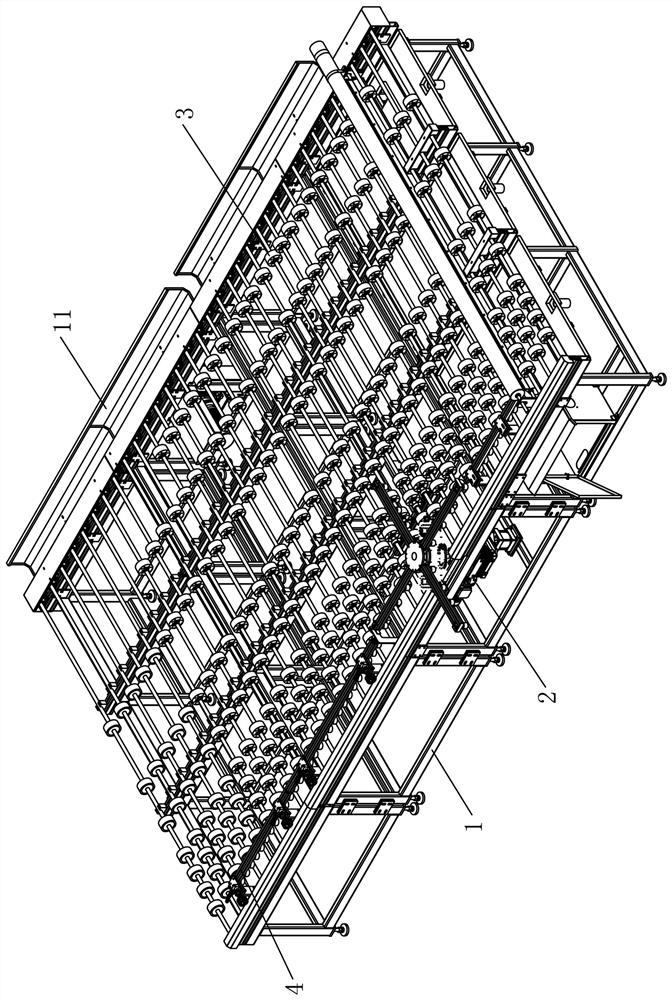

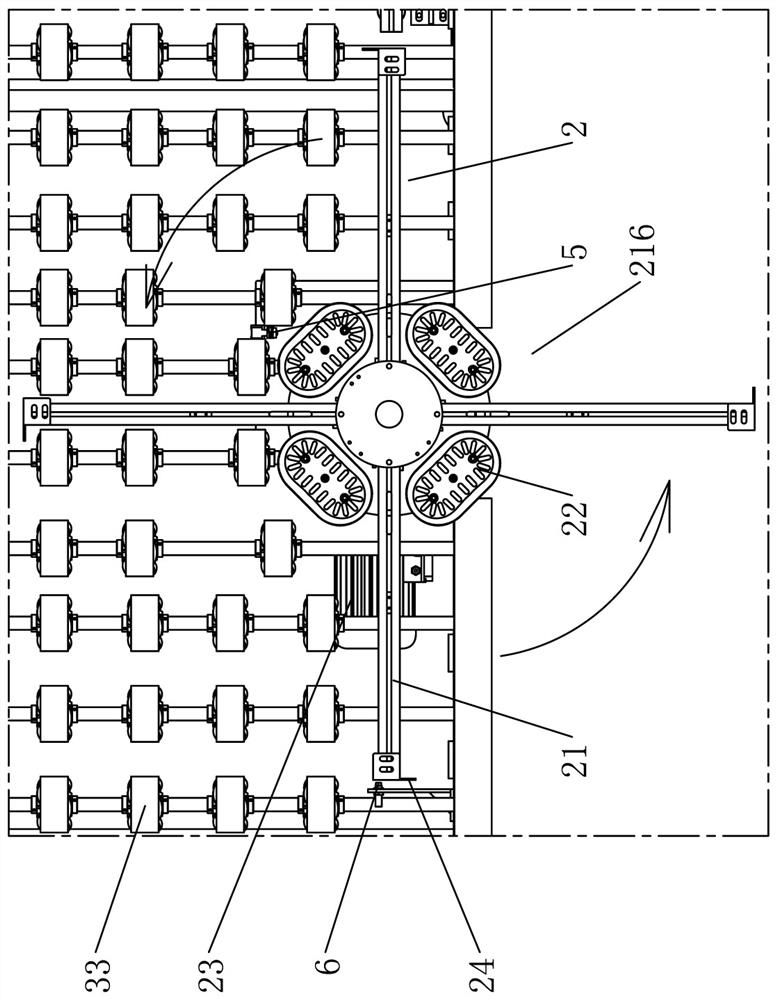

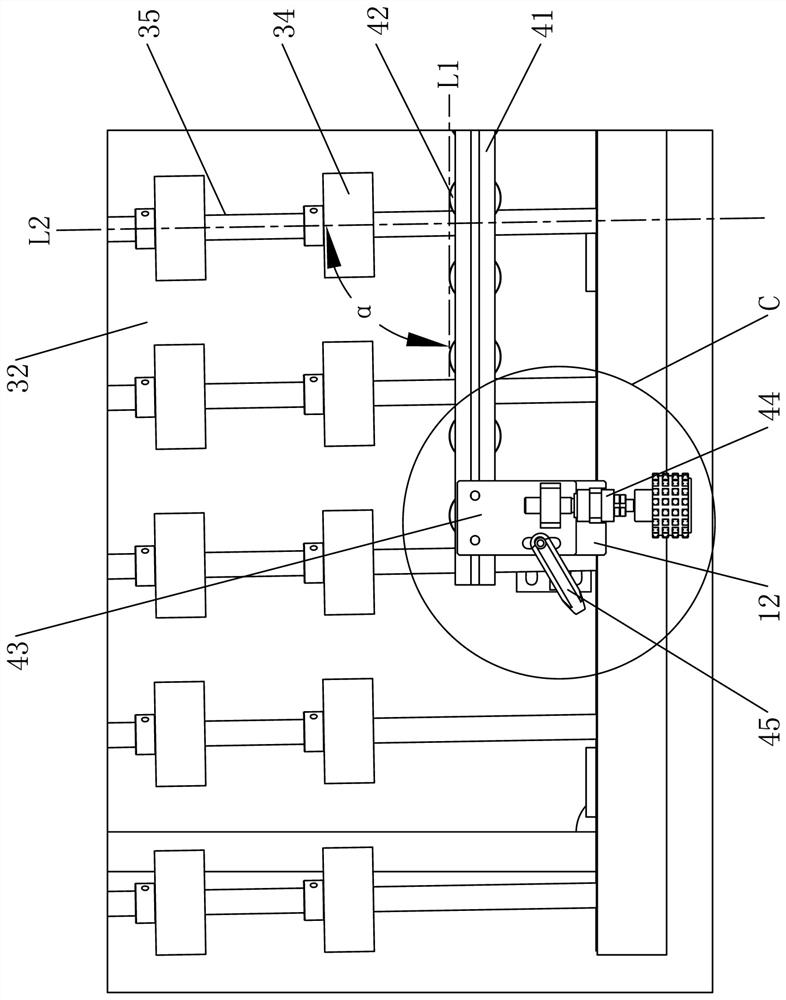

[0041] see figure 1 and figure 2 As shown, a glass horizontal linear conversion table includes a table assembly 1, a supporting and conveying roller group 3 and a side guide wheel group 4 arranged on the table assembly 1, and the side guide wheel group 4 Arranged in a straight line along the glass transmission direction, and located on the upper side of the supporting and conveying roller group 3, the table assembly 1 is also provided with a glass lifting angle rotation for lifting a corner of the glass and assisting the rotation of the glass. A driving device 2 , a glass linear in-position detection element 5 for detecting the in-position condition of the glass, and a glass rotation in-position detection element 6 for detecting the rotational position of the glass lift angle rotation driving device 2 . The platform assembly 1 is composed of a plurality of pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com