Color press

A printing press, color technology, applied in the direction of winding strip, thin material handling, transportation and packaging, etc., can solve the problems of inability to guarantee stable substrate tension and inaccurate overprinting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

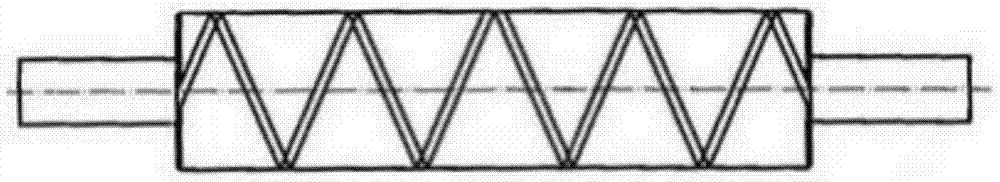

[0019] Figure 4 The color printing machine shown is mainly composed of the unwinding part A, the unwinding traction part B, the printing part C, the drying part D, the winding traction part E and the winding part F framed by double dotted lines. constitute. Wherein the unwinding part A, the unwinding traction part B, the drying part D, the winding traction part E and the winding part F are mostly related parts of an existing color printing machine.

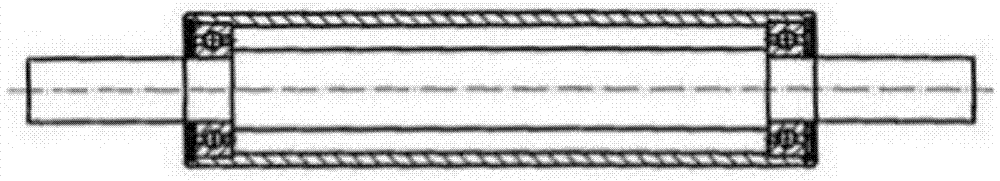

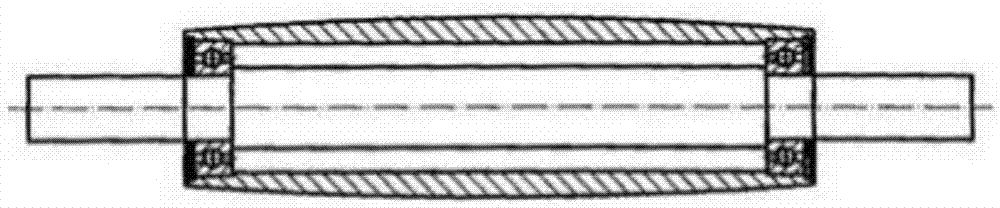

[0020] Figure 5 The printing part C shown has 8 printing units, that is, printing units 2, 3, 4, 5, 7, 8, 9, and 10. The substrate is web 1, and on the traveling path of web 1, in A vacuum suction roller 12 is housed before the first printing unit 2, a vacuum suction roller 11 is housed after the last printing unit 10, and a vacuum suction roller 11 is also housed between the fourth printing unit 5 and the fifth printing unit 6. Vacuum adsorption rollers 6 , the structural principles and installation methods of these vacuum a...

Embodiment 2

[0025] A kind of color printing machine of this embodiment is compared with a kind of color printing machine of embodiment 1, except that the synchronous roller in front of the first printing unit is replaced by a pair of ordinary rollers that sandwich the two sides of the substrate Figure 5 Except the vacuum suction roller 12 in, other parts are identical with a kind of color printing machine of embodiment 1. This pair of ordinary rollers is also connected with the vacuum adsorption roller through pulleys and transmission belts. During operation, the linear speed of the roller surface is the same as that of other vacuum adsorption rollers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com