Electron crosslinking enhanced PE film and preparation method thereof

An electronic cross-linking and film technology, which is applied in chemical instruments and methods, flat products, and other household appliances, etc., can solve the problems of insufficient strength of PE base film, easy stretching and deformation, overprinting, puncture and broken bags, etc., and reach the heat sealing temperature Wide range, resistance to mechanical scratches on the surface, and high heat-sealing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

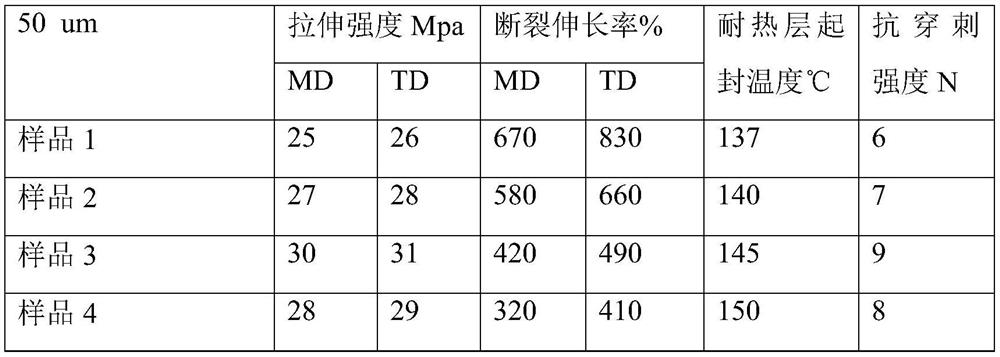

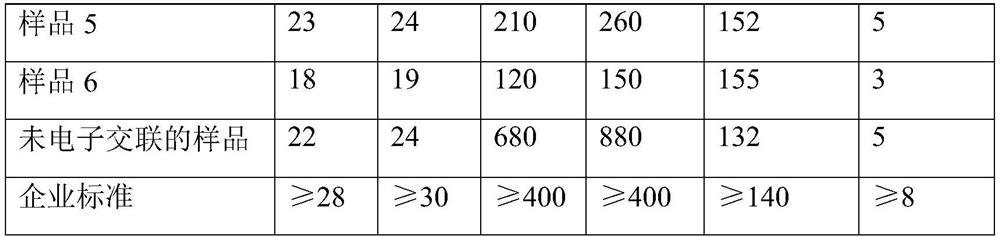

Embodiment 1

[0053] A kind of preparation method of the PE film that electronic cross-linking strengthens, comprises the following steps:

[0054] Blown film→electronic cross-linking→(printing)→composite→curing→slitting

[0055] Firstly, the raw materials required for the PE film are blown, then electronically cross-linked, printed as required, then compounded, matured, and cut to obtain the electronically cross-linked enhanced PE film.

[0056] Blown film: PE film thickness uniformity control: average deviation ≤ 3%, limit deviation ≤ 5%.

[0057] Described film blowing comprises the following steps:

[0058] In the first layer, HDPE, the raw material of the heat-resistant layer, is added to the hopper of the extruder, melted at a temperature of 170-200°C, and enters the die;

[0059] In the second layer, the raw material LDPE of the first cross-linking layer is put into the hopper of the extruder, melted at a temperature of 170-200°C, and enters the die;

[0060] In the third layer, t...

Embodiment 2

[0098] A PE film enhanced by electronic cross-linking, from top to bottom: heat-resistant layer, first cross-linked layer, second cross-linked layer, third cross-linked layer, fourth cross-linked layer, fifth cross-linked layer , the sixth cross-linked layer, the seventh cross-linked layer, and the composite layer;

[0099] The material of the heat-resistant layer is HDPE, and the layer thickness is 25%; the material of the first cross-linked layer is LDPE, and the layer thickness is 8%; the material of the second cross-linked layer is LDPE, and the layer thickness is 8%; The material of the third cross-linked layer is LDPE, and the layer thickness is 8%; the material of the fourth cross-linked layer is LDPE, and the layer thickness is 8%; the material of the fifth cross-linked layer is LDPE, and the layer thickness is 8%; The material of the sixth cross-linked layer is LDPE, and the layer thickness is 8%; the material of the seventh cross-linked layer is LDPE, and the layer t...

Embodiment 3

[0102] A PE film enhanced by electronic cross-linking, from top to bottom: heat-resistant layer, first cross-linked layer, second cross-linked layer, third cross-linked layer, fourth cross-linked layer, fifth cross-linked layer , the sixth cross-linked layer, the seventh cross-linked layer, and the composite layer;

[0103] The material of the heat-resistant layer is HDPE, and the layer thickness is 20%; the material of the first cross-linked layer is LDPE, and the layer thickness is 10%; the material of the second cross-linked layer is LDPE, and the layer thickness is 10%; The material of the third cross-linked layer is LDPE, and the layer thickness is 10%; the material of the fourth cross-linked layer is LDPE, and the layer thickness is 10%; the material of the fifth cross-linked layer is LDPE, and the layer thickness is 10%; The material of the sixth cross-linked layer is LDPE, and the layer thickness is 10%; the material of the seventh cross-linked layer is LDPE, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com