Interlayer heat reflection fabric and preparation method thereof

A heat reflection, interlayer technology, applied in chemical instruments and methods, layered products, glass/slag layered products, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

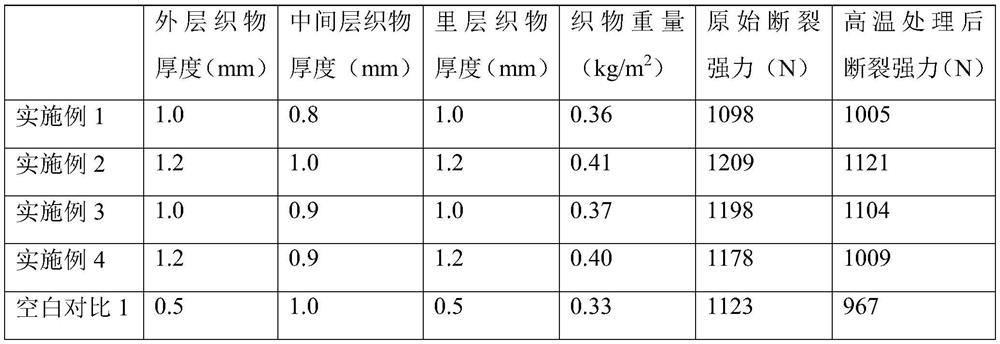

Embodiment 1

[0022] A sandwich heat-reflecting fabric, comprising an outer layer, a middle layer and an inner layer, the middle layer is a heat-insulating cloth, and the outer layer and the inner layer are electrospun layers containing reflective particles.

[0023] Preferably, the thickness of the outer layer is 1.0 mm, the thickness of the inner layer is 1.0 mm, and the thickness of the middle layer is 0.8 mm. The heat insulation cloth is a plain weave fabric with a warp and weft density of 60 threads / cm. The count of the yarn is 40S.

[0024] Preferably, the heat insulation cloth is glass fiber cloth.

[0025] A method for preparing an interlayer heat reflective fabric, comprising the following steps:

[0026] S1. Carry out ball milling to the fly ash floating beads, sieve the fly ash of the ball mill, after the fly ash is sieved to 8000 meshes, then place it in dilute acid solution for cleaning to obtain the purified fly ash floating beads;

[0027] S2. Add the purified fly ash float...

Embodiment 2

[0031] A sandwich heat-reflecting fabric, comprising an outer layer, a middle layer and an inner layer, the middle layer is a heat-insulating cloth, and the outer layer and the inner layer are electrospun layers containing reflective particles.

[0032] Preferably, the thickness of the outer layer is 1.2 mm, the thickness of the inner layer is 1.2 mm, and the thickness of the middle layer is 1.0 mm. The heat insulation cloth is a plain weave fabric with a warp and weft density of 60 threads / cm. The count of the yarn is 40S.

[0033] Preferably, the heat insulation cloth is basalt fiber cloth.

[0034] A method for preparing an interlayer heat reflective fabric, comprising the following steps:

[0035] S1. Carry out ball milling of the fly ash floating beads, sieve the fly ash of the ball mill, the fly ash is 10000 mesh after sieving, and then place it in dilute acid solution for cleaning to obtain the purified fly ash floating beads;

[0036] S2. Add the purified fly ash flo...

Embodiment 3

[0040] A sandwich heat-reflecting fabric, comprising an outer layer, a middle layer and an inner layer, the middle layer is a heat-insulating cloth, and the outer layer and the inner layer are electrospun layers containing reflective particles.

[0041] Preferably, the thickness of the outer layer is 1.0 mm, the thickness of the inner layer is 1.0 mm, and the thickness of the middle layer is 0.9 mm. The heat insulation cloth is a plain weave fabric with a warp and weft density of 60 threads / cm. The count of the yarn is 40S.

[0042] Preferably, the heat insulation cloth is any one of glass fiber cloth or basalt fiber cloth.

[0043] A method for preparing an interlayer heat reflective fabric, comprising the following steps:

[0044] S1. Carry out ball milling to the fly ash floating beads, sieve the fly ash of the ball mill, the fly ash is sieved to 8500 meshes, and then be placed in dilute acid solution for cleaning to obtain the purified fly ash floating beads;

[0045] S2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com