Electric single-beam bridge-type travelling crane for draining pump room

An electric, single-girder technology, applied in the direction of trolley cranes, load suspension components, safety devices, etc., can solve problems such as potential safety hazards, affecting the efficiency of drainage pump rooms, personal safety of operators, and economic losses to enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

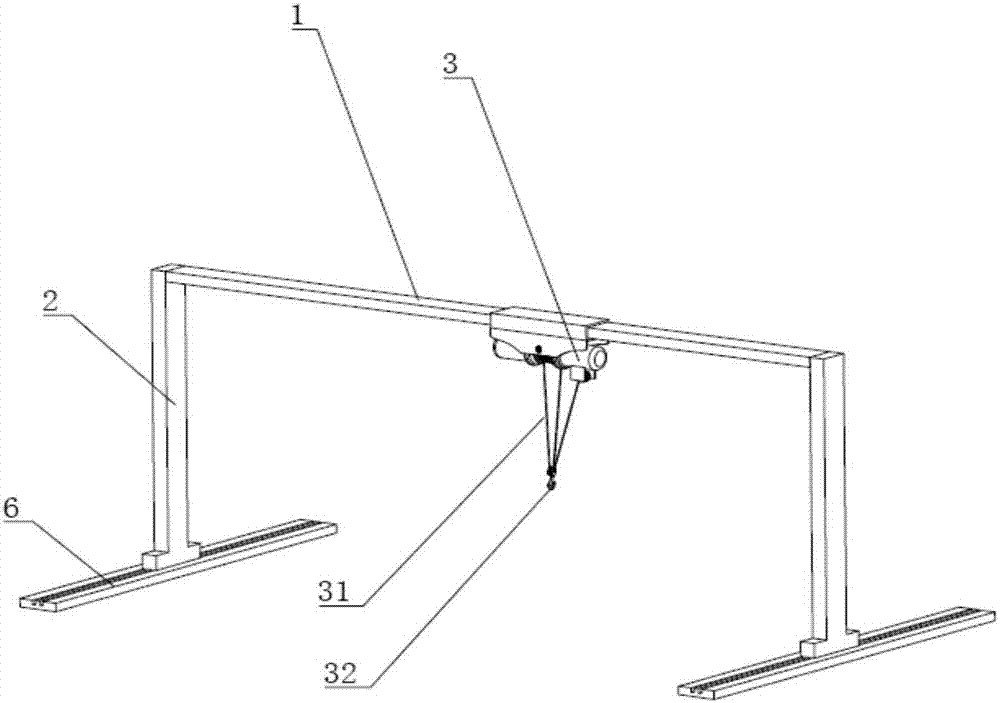

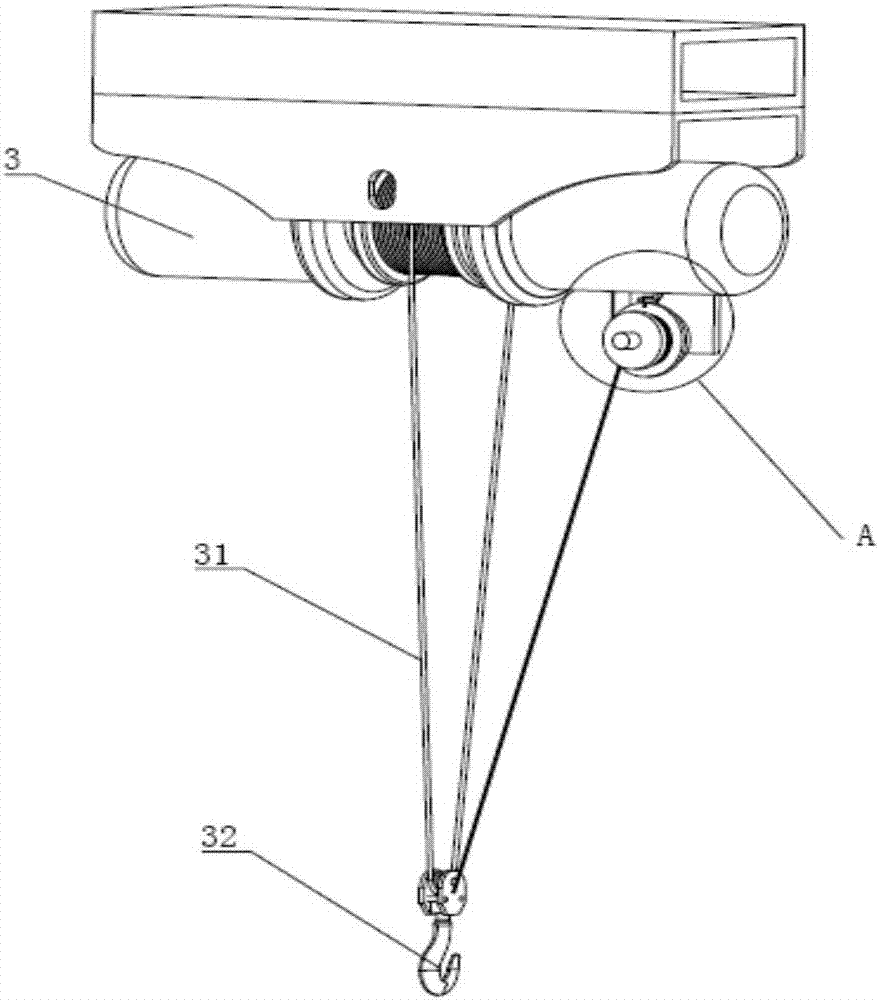

[0026] Embodiment 1: An electric single-girder bridge crane for drainage pump room, such as figure 1 As shown, a beam 1 is included, and a bracket 2 for supporting the beam 1 is arranged at both ends of the beam 1. The bracket 2 can move on the rail 6 laid on the wharf, and an electric hoist 3 is slidably connected to the beam 1. , the rotating shaft of the electric hoist 3 is connected with a suspension hook 32 for lifting heavy objects through a suspension rope 31 .

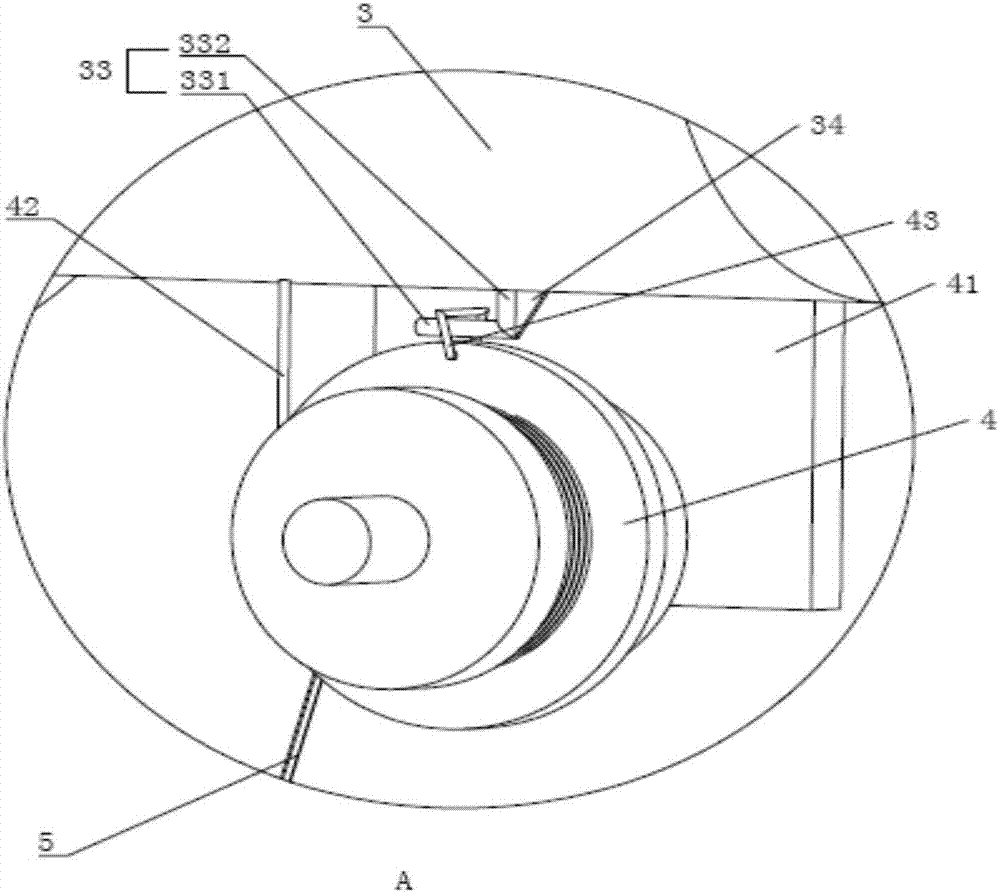

[0027] Such as figure 2 and 3 As shown, two connecting plates 41 are arranged below the electric hoist 3, and a turntable 4 is rotatably connected between the connecting plates 41, and a traction rope 5 is wound on the turntable 4, and one end of the traction rope 5 is fixedly connected to the turntable 4 , the other end is fixedly connected with the suspension hook 32, and an elastic return rope 42 is fixedly connected with the electric hoist 3. Under the action of pulling force, the traction rope 5 can be...

Embodiment 2

[0029] Embodiment 2: An electric single-girder bridge crane for a drainage pump house, the difference from Embodiment 1 is that, as image 3 As shown, a warning bell 51 is hung near the end of the suspension hook 32 on the traction rope 5 . Hang the warning bell 51 on an end close to the suspension hook 32, so that the warning bell 51 will not be rolled up together when the traction rope 5 is wound up on the turntable 4, so that the warning bell 51 is not easy to be crushed; Hook 32 is all relatively slow when lifting and lowering under normal conditions, and operation is relatively stable, so it is difficult to make warning bell 51 vibrate quickly and send a larger ringing sound, and it is difficult to affect the normal work of the staff. When the suspension hook 32 pulls the traction rope 5 and falls rapidly, the warning bell 51 can be violently shaken, thereby producing a faster and louder ringtone to remind the staff that the suspension rope 31 is broken; The ups and down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com