Device and method for producing temperature-sensing package inserts

A technology for temperature-sensing packs and inserts, which is applied in the field of production devices for temperature-sensing pack inserts, can solve the problems of low material utilization rate, high product cost, safety accidents, etc. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

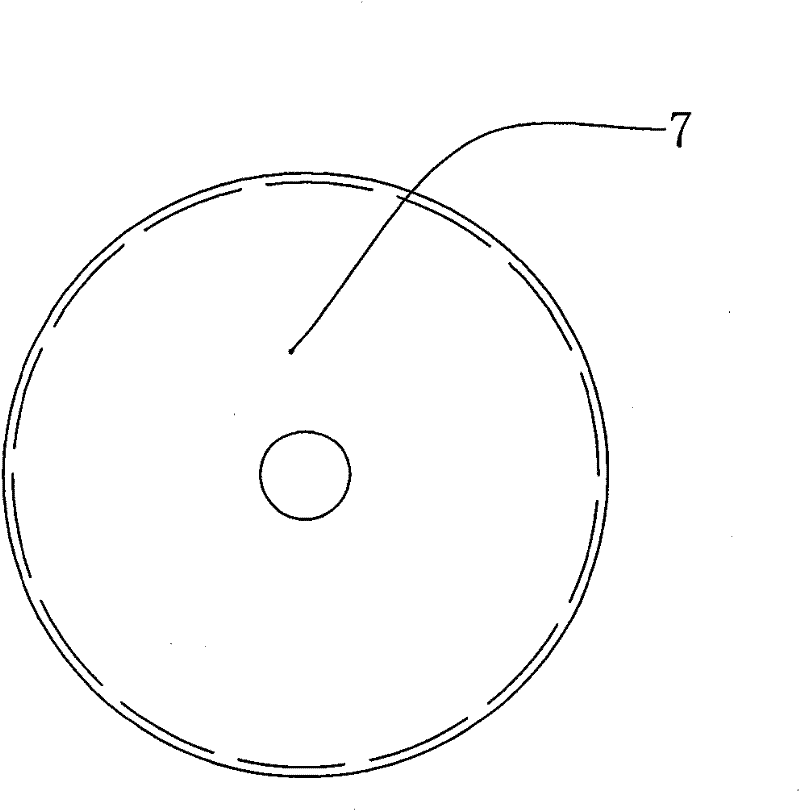

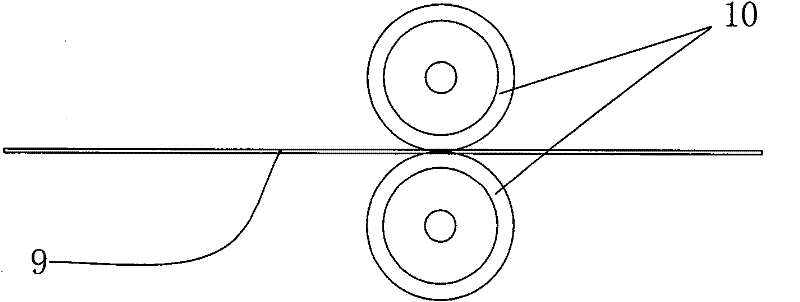

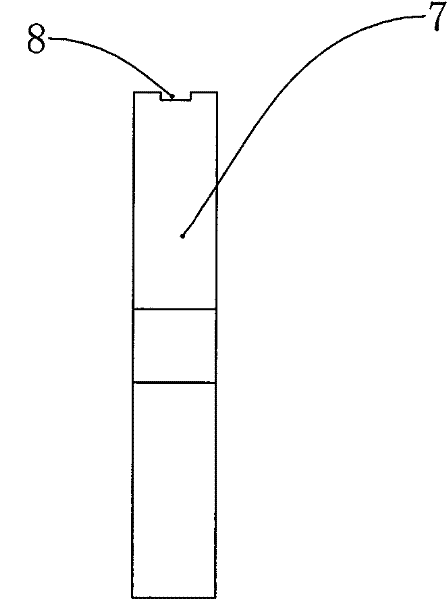

[0023] The production device of the temperature-sensing package insert provided in this embodiment is modified on the basis of the existing spring machine. The transformation is mainly aimed at the mechanical structure of the feeding mechanism and the control program for the temperature-sensing package insert. Because the temperature-sensing package insert is strip-shaped, so the present invention at first sets the outlet of the discharge part 1 as a flat rectangle, and secondly, changes the wire feeding groove 8 of the feeding wheel 7 into a flat rectangle groove (see Figure 3a , Figure 3b ).

[0024] The following illustrates the production of the production device based on the above-mentioned temperature-sensitive package insert Figure 1a , Figure 1b The method for inserting the temperature sensing package includes the following steps:

[0025] 1) According to the bending shape and size of the prefabricated temperature-sensing package insert, compile the automatic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com