Hydraulic support crane based on hydraulic buffer principle

A hydraulic buffer and hydraulic technology, applied in cranes, transportation and packaging, etc., can solve problems such as poor buffering effect, car collision accidents, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

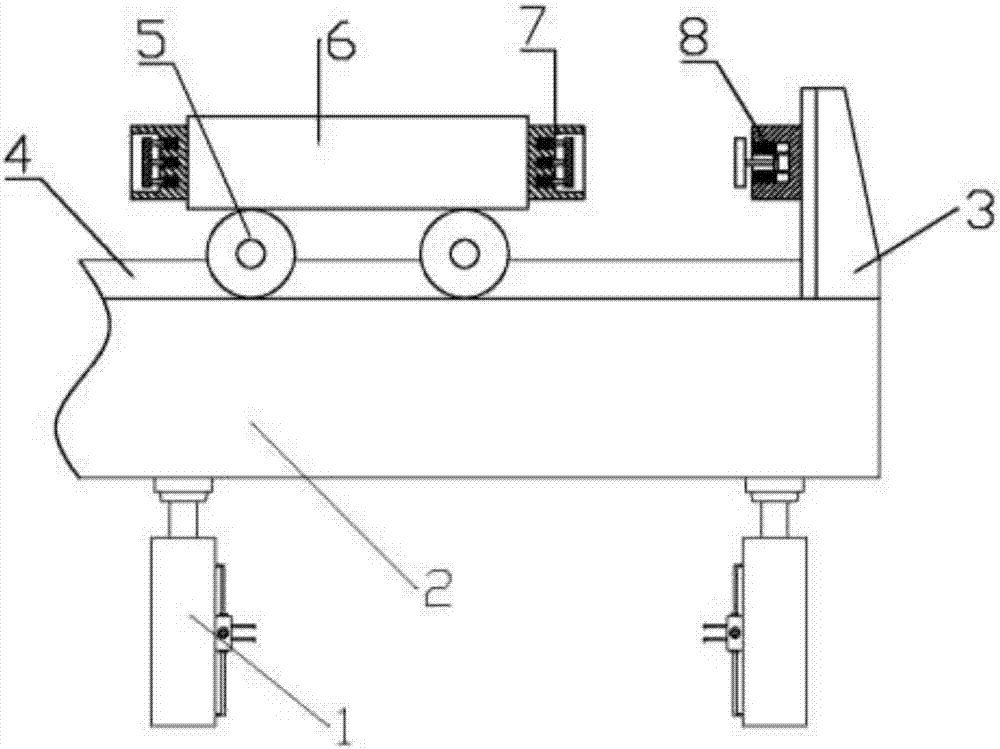

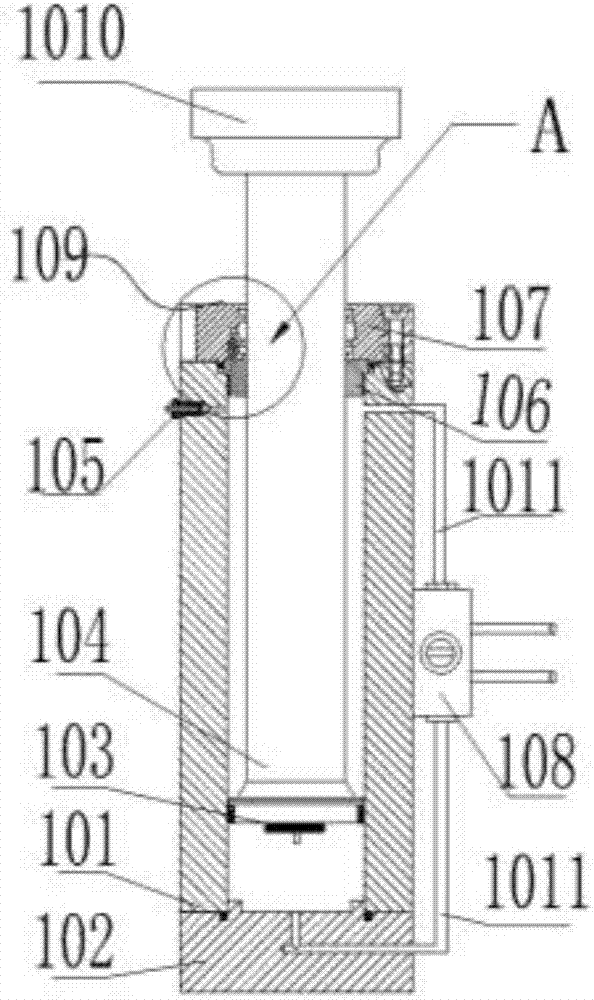

[0024] see Figure 1-Figure 5 , a hydraulic support crane based on the hydraulic buffer principle, including a support beam 2, four hydraulic legs 1 are provided on the underside of the support beam 2, and the hydraulic legs 1 include a cylinder 101, which is characterized in that the The lower end of the cylinder barrel 101 is connected to the cylinder bottom 102, and the cylinder barrel 101 contains a piston 104 rod inside, and a hydraulic cylinder displacement sensor 103 is installed at the tail end of the piston rod 104, and the hydraulic cylinder displacement sensor 103 can grasp the extension of the piston rod 104 conveniently and quickly. Adjust the extension length of several other hydraulic outriggers 1 accordingly to ensure the level of the crane;

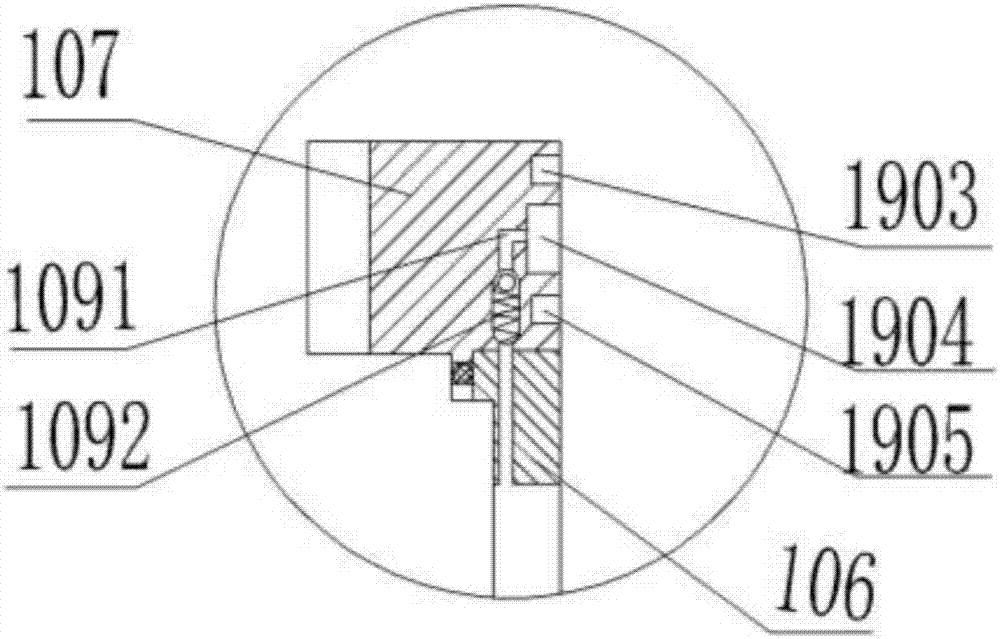

[0025] The vent hole plug is located on the left side of the upper part of the cylinder 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com