Safety Control Method for Preventing Tube Burn-through of Tube Heating Furnace

A tubular heating furnace, safety control technology, applied in the direction of furnace control devices, lighting and heating equipment, furnaces, etc., can solve problems such as poor safety, and achieve the effects of avoiding dangerous consequences, good reliability and usability, and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

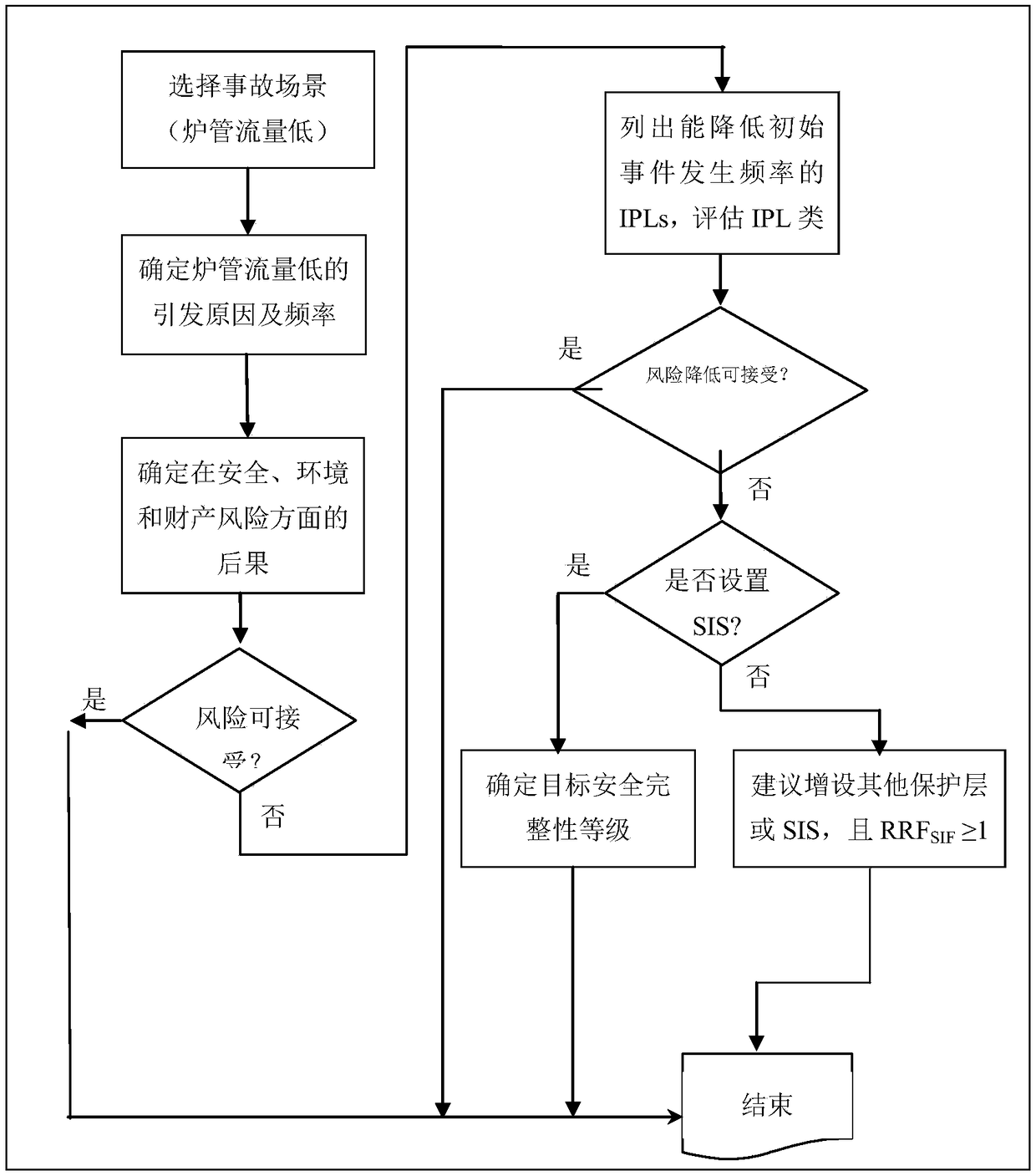

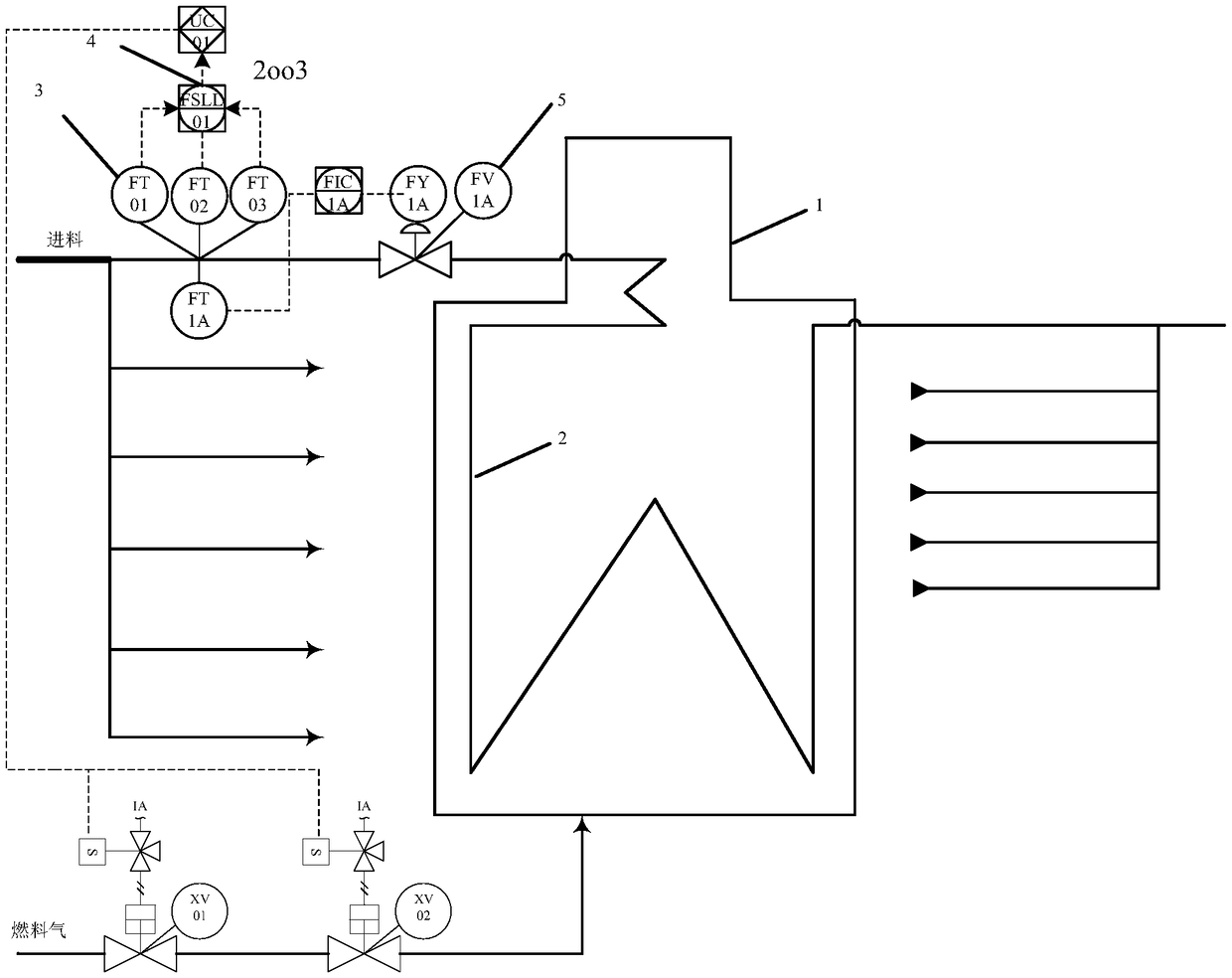

[0024] A safety control method for preventing burn-through of tube heating furnace tubes, such as figure 1 shown, including the following steps:

[0025] 1. Analysis of low risk of heating furnace tube flow

[0026] Using Process Hazard Analysis (PHA) or Hazard and Operability Analysis (HAZOP) methods, according to the furnace process technical regulations and pipeline and instrument flow charts, identify and analyze the causes of low furnace tube flow and the consequences of such deviations, Find out the existing protective measures and determine whether the independent protection layer (IPL) meets the risk reduction requirements, and sort out the existing or proposed additional safety instrumented function loops.

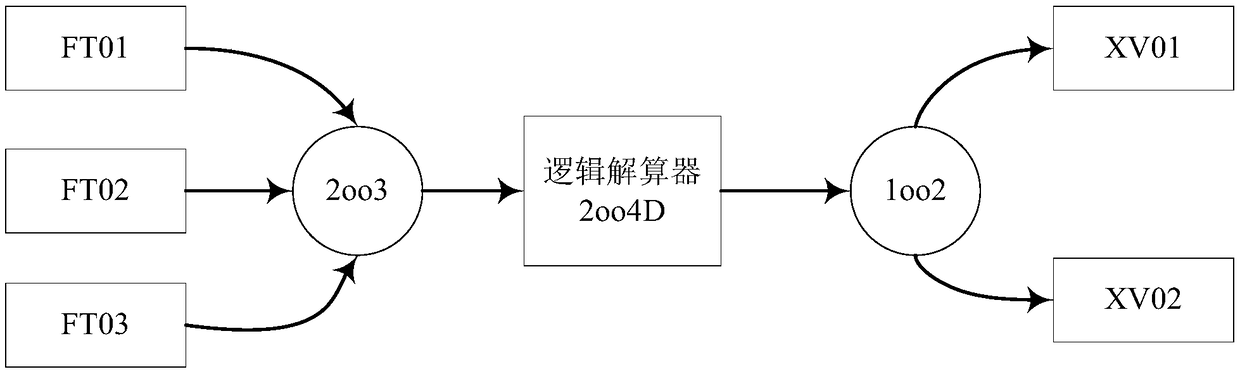

[0027] 2. Determine the SIL level of the safety instrument function

[0028] On the basis of risk analysis, the safety instrument function is identified, and the safety integrity level of the low-low interlocking circuit of the furnace tube flow is determined by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com