Digital display torsion testing machine for teaching

A torsion testing machine and torsion angle technology, applied in teaching models, educational appliances, torque measurement, etc., can solve problems such as waste, roughness, and complicated operation, and achieve the effect of intuitive principle, simple structure, and safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

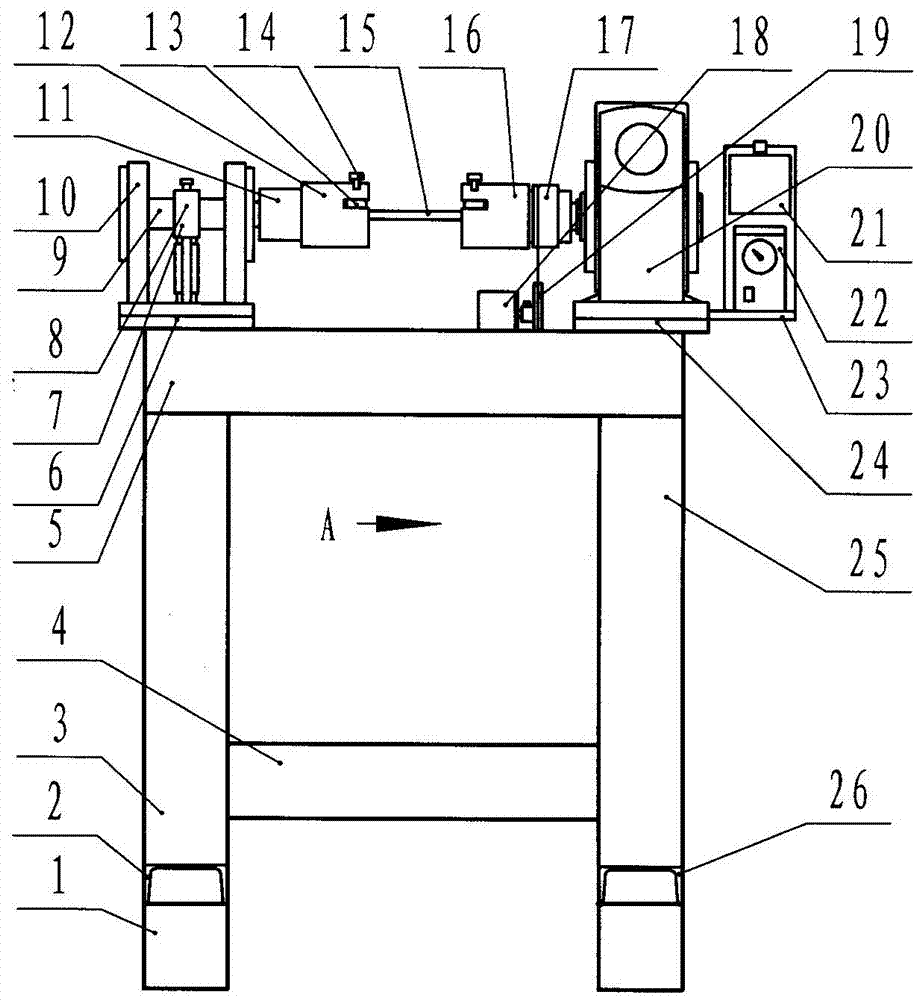

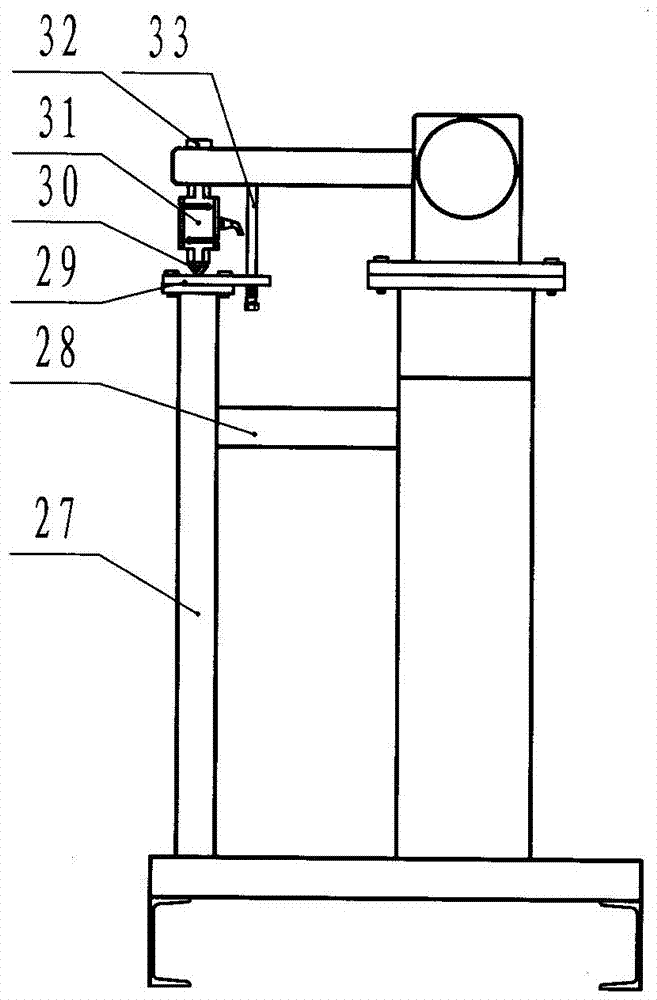

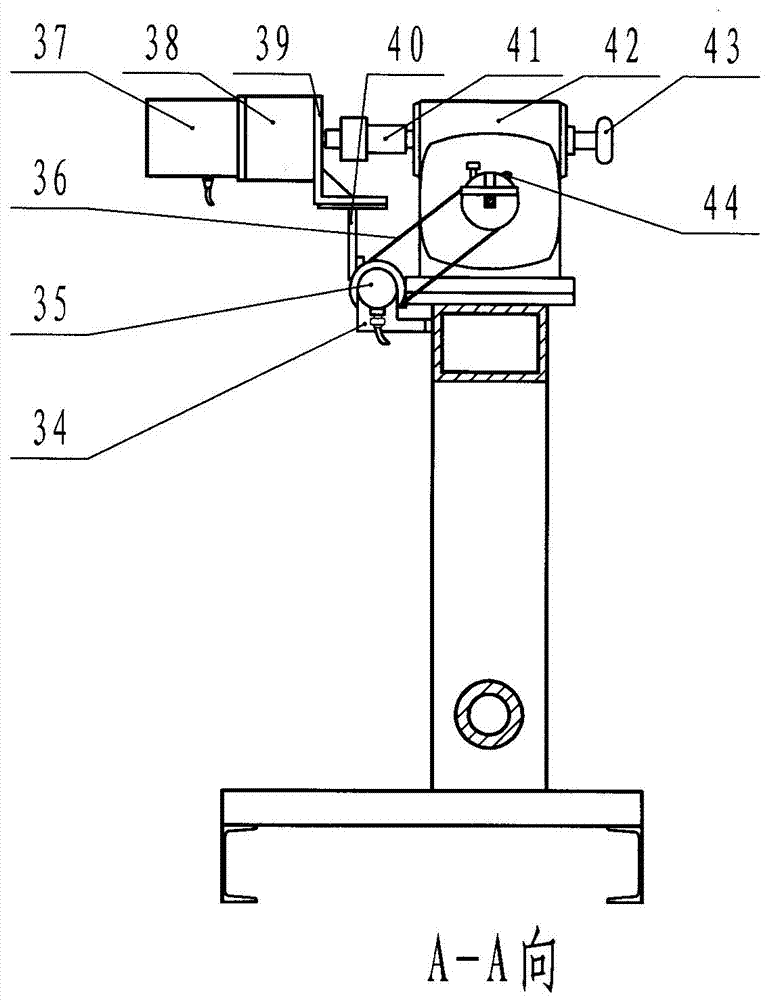

[0046] Such as figure 1 , figure 2 , image 3 with Figure 4 The shown digital display torsion testing machine for teaching includes: frame 1, variable speed loading assembly 20, torque measurement assembly 7, chuck assembly 11, torsion angle measurement assembly 18, and display recording assembly 45;

[0047] The frame 1 includes: a left base 2, a left column 3, a transverse connecting pipe 4, a seat beam 5, a left seat plate 6, a right seat plate 24, a right column 25, a right base 26, a small column 27, and a small beam 28;

[0048] Wherein, the left column 3, the seat beam 5, and the right column 25 are made of frame-shaped section square pipe steel, the left base 2, the right base 26, the small column 27, and the small beam 28 are made of channel steel, and the transverse connecting pipe 4 is a circle Steel pipe, each piece is firmly electric welded together.

[0049] As a preferred structure, the variable speed loading assembly 20 includes: reversing switch 21, spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com