Separation system for bottle bodies, labels and covers of waste plastic bottles and machining method of separation system

A waste plastic and separation system technology, applied in the label and cap separation system and its processing, the bottle field, can solve the problems of easy secondary pollution, tight label bonding and other problems, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

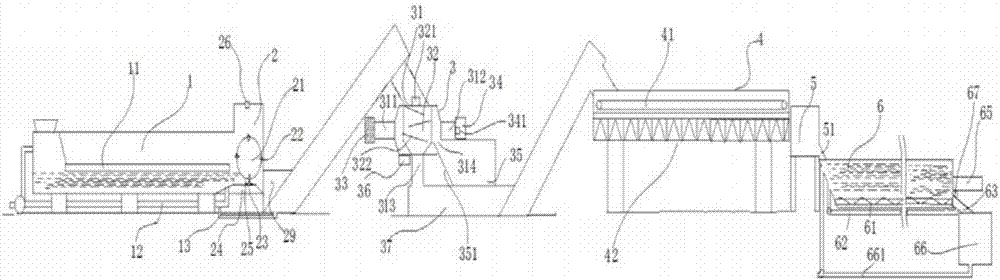

[0050] The separation system of the bottle of the waste plastic bottle of the present embodiment, label and cap, as figure 1 As shown, it includes soaking tank 1, stripping mechanism 2, air selection mechanism 3 and selection platform 4 arranged in sequence according to the process, and the soaking pool 1 and stripping mechanism 2 are connected; stripping mechanism 2, wind selection mechanism 3 and selection platform 4 are sequentially arranged Connected through the feeding auger; the tail end of the selection platform 4 is dropped into the crusher 5; the crusher 5 communicates with the beginning of the separation tank 6 through the discharge port 51; the end of the separation tank 6 passes through the plastic particle discharge port 63 It communicates with the plastic particle collection box 66; the separation pool 6 is filled with separation liquid.

[0051] The bottle, label and cap separation system of waste plastic bottles in this embodiment, in the specific use process, ...

Embodiment 2

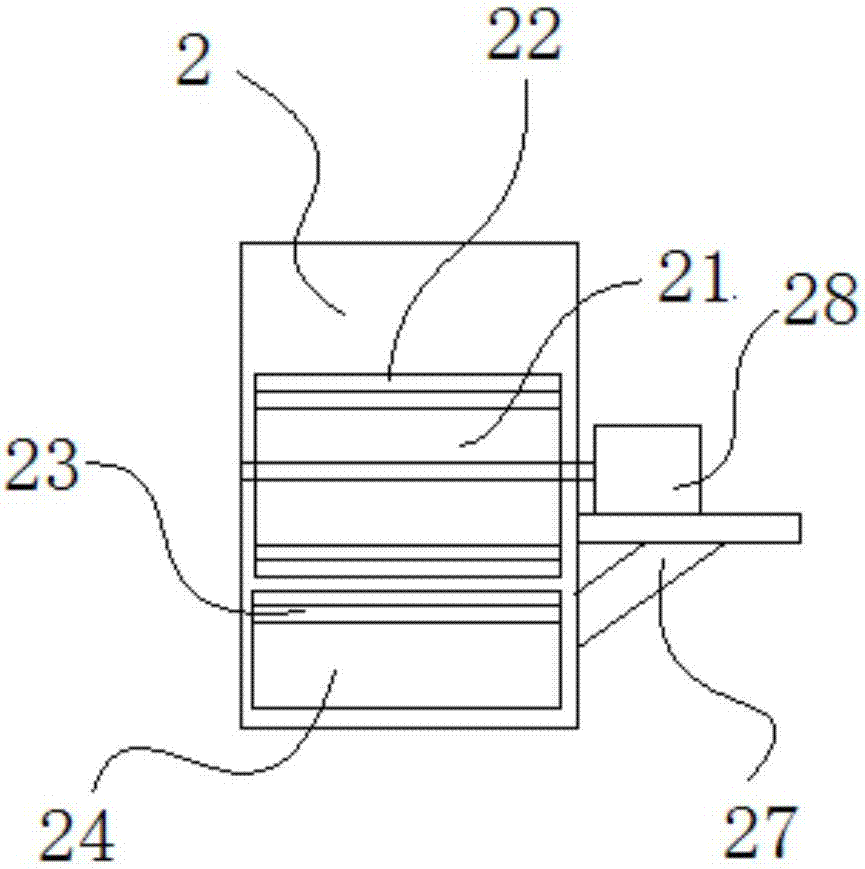

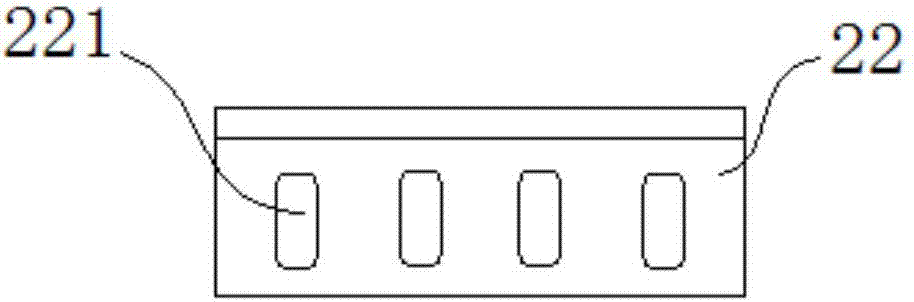

[0053] The separation system of the bottle of the waste plastic bottle of the present embodiment, label and cap, basic structure is the same as embodiment 1, difference and improvement are: as figure 2 As shown, a rotating cylinder 21 is fixed horizontally inside the peeling mechanism 2, a movable knife 22 is fixed on the outer edge of the rotating cylinder 21, a knife seat 24 is fixed below the rotating cylinder 21, and a knife seat 24 is fixed on the surface of the knife seat 24 to cooperate with the movable knife 22. The fixed knife 23, the gap between the movable knife 22 and the fixed knife 23 forms a knife edge 25, and the knife edge 25 is connected to the bottle collection box 29; 32. The upper end of the roller net cylinder 32 is externally connected to the discharge port of the feeding auger, and the lower end is externally connected to the waste bottle collection and transfer mechanism 37 through the waste bottle discharge pipe 313; one side of the horizontal barrel ...

Embodiment 3

[0063] The separation system of bottles, labels and caps of waste plastic bottles of this embodiment has the same basic structure as that of Embodiment 2, the difference and improvement are: a circulating water pipe 12 is arranged at the bottom of the soaking pool 1, and the circulating water in the soaking pool 1 flows to After the knife edge 25, return to the lower part of the feeding port of the feeding auger, through the flow of water, the bottle body is moved towards the direction of the knife edge, which improves the separation production efficiency; the stripping mechanism 2 is a box structure, and the top of the box is provided with a spray The shower nozzle 26 sprays the blade of the movable knife 22 to keep the blade in a clean state, so as to avoid the remaining mark paper on the blade from affecting the separation efficiency; The air outlet pipe 312 is externally connected to avoid air backflow affecting separation; at the bottom of the air outlet pipe 312, the hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com