Primary treatment equipment used for construction site sewage

A preliminary treatment and construction site technology, applied in water/sewage treatment, multi-stage water/sewage treatment, adsorption water/sewage treatment, etc., can solve problems such as affecting the environment and wasting water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

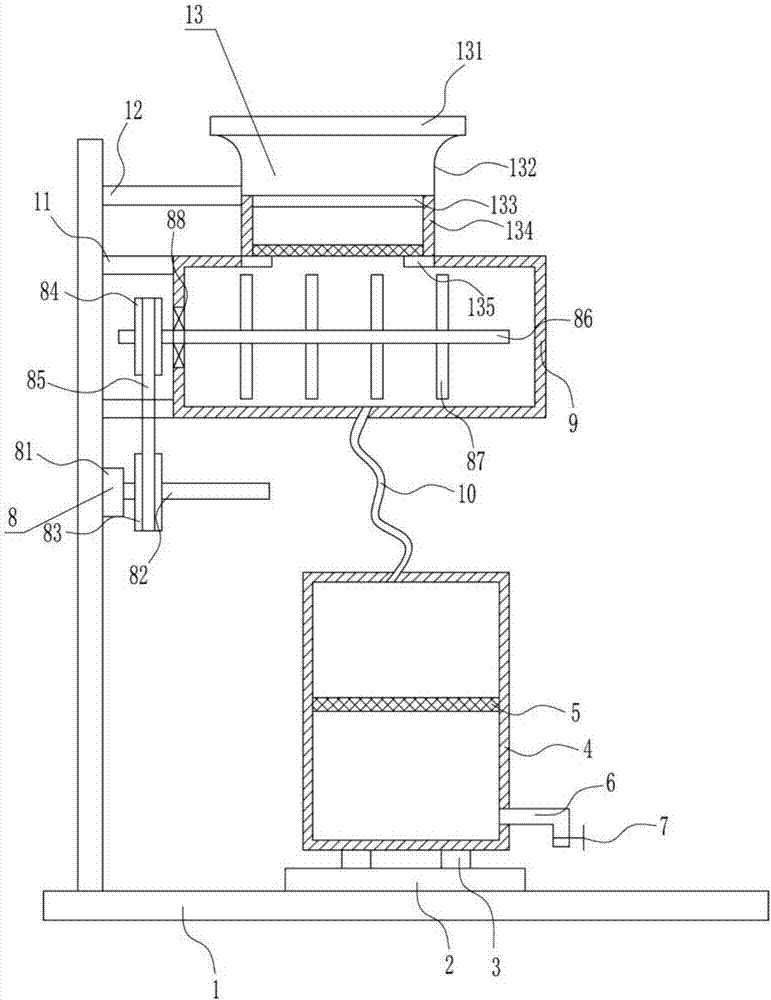

Embodiment 1

[0021] A primary treatment equipment for construction site sewage, such as Figure 1-3As shown, it includes bottom plate 1, slide rail 2, slider 3, first box body 4, screen plate 5, first water pipe 6, valve 7, stirring device 8, second box body 9, second water pipe 10, the first A cross bar 11, a second cross bar 12 and a blanking device 13. A slide rail 2 is installed in the middle of the top of the bottom plate 1 through a bolt connection. The slide rail 2 is horizontally arranged, and the slide rail 2 is provided with a sliding block 3 matching it. , the slide rail 2 is slidingly matched with the slider 3, and the top of the slider 3 is connected with a bolt to install the first box body 4, the first box body 4 is provided with a mesh plate 5, the mesh plate 5 is arranged horizontally, and the mesh plate 5 The left side and the right side are connected to the inner side of the first box body 4 by means of bolt connection, the first water pipe 6 is connected to the lower ri...

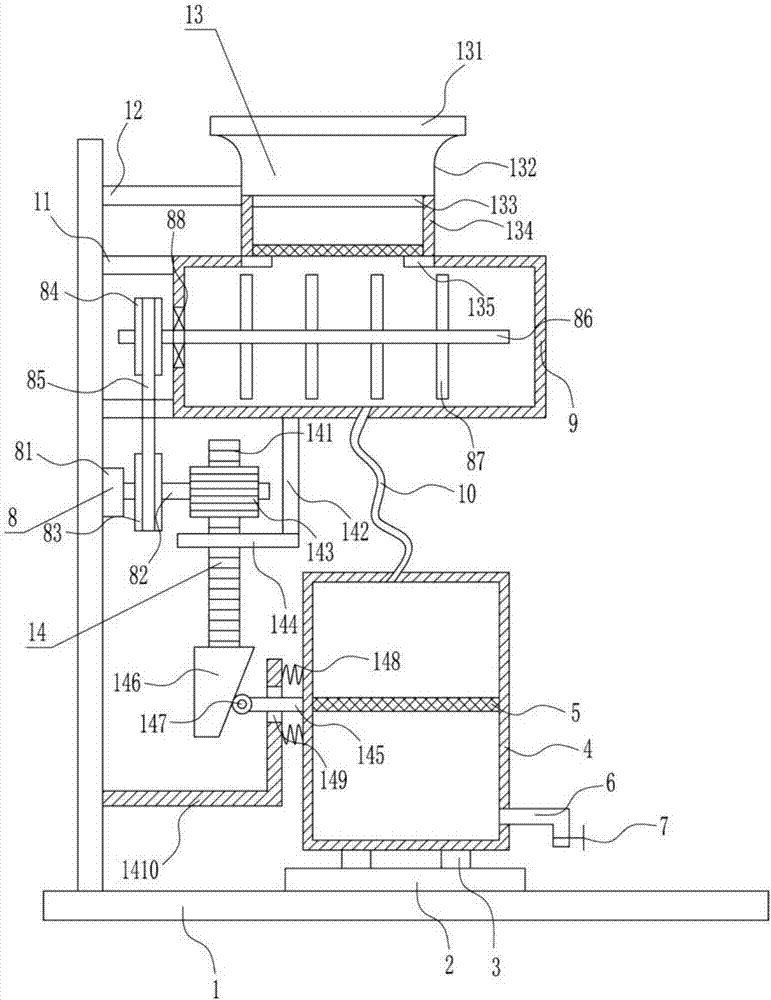

Embodiment 2

[0023] A primary treatment equipment for construction site sewage, such as Figure 1-3 As shown, it includes bottom plate 1, slide rail 2, slider 3, first box body 4, screen plate 5, first water pipe 6, valve 7, stirring device 8, second box body 9, second water pipe 10, the first A cross bar 11, a second cross bar 12 and a blanking device 13. A slide rail 2 is installed in the middle of the top of the bottom plate 1 through a bolt connection. The slide rail 2 is horizontally arranged, and the slide rail 2 is provided with a sliding block 3 matching it. , the slide rail 2 is slidingly matched with the slider 3, and the top of the slider 3 is connected with a bolt to install the first box body 4, the first box body 4 is provided with a mesh plate 5, the mesh plate 5 is arranged horizontally, and the mesh plate 5 The left side and the right side are connected to the inner side of the first box body 4 by means of bolt connection, the first water pipe 6 is connected to the lower r...

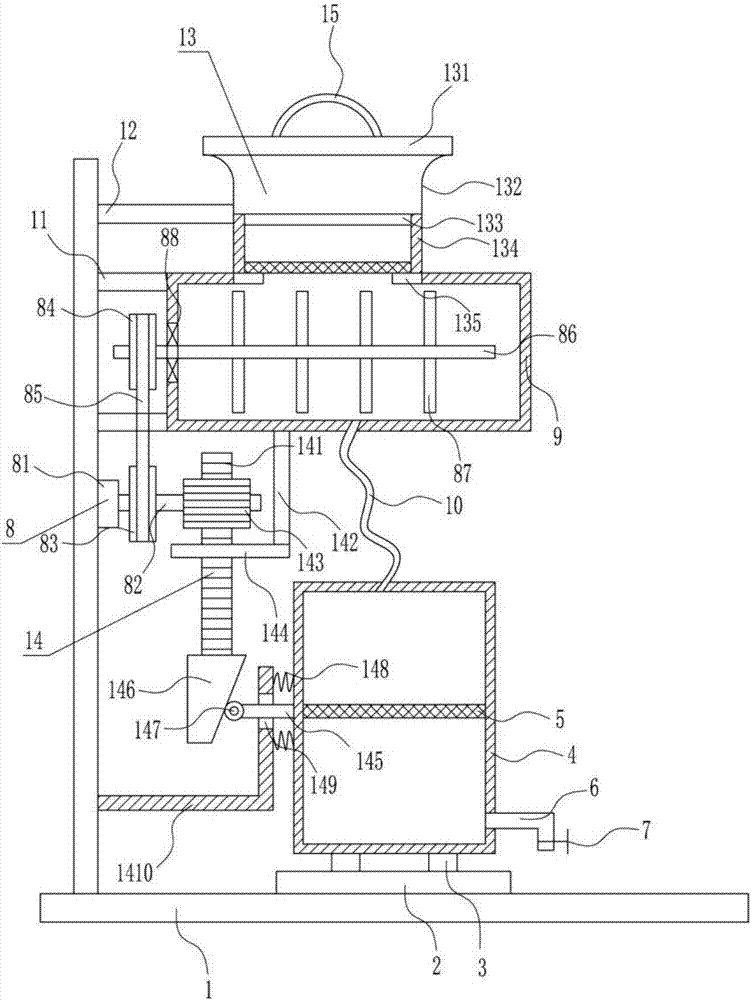

Embodiment 3

[0026] A primary treatment equipment for construction site sewage, such as Figure 1-3 As shown, it includes bottom plate 1, slide rail 2, slider 3, first box body 4, screen plate 5, first water pipe 6, valve 7, stirring device 8, second box body 9, second water pipe 10, the first A cross bar 11, a second cross bar 12 and a blanking device 13. A slide rail 2 is installed in the middle of the top of the bottom plate 1 through a bolt connection. The slide rail 2 is horizontally arranged, and the slide rail 2 is provided with a sliding block 3 matching it. , the slide rail 2 is slidingly matched with the slider 3, and the top of the slider 3 is connected with a bolt to install the first box body 4, the first box body 4 is provided with a mesh plate 5, the mesh plate 5 is arranged horizontally, and the mesh plate 5 The left side and the right side are connected to the inner side of the first box body 4 by means of bolt connection, the first water pipe 6 is connected to the lower r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com