Eccentric wheel rotation mechanism

A technology of rotating mechanism and eccentric wheel, applied in mechanical equipment, transmission device, transmission device parts, etc., can solve the problems of large acceleration change and difficult to achieve, and achieve the effect of reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

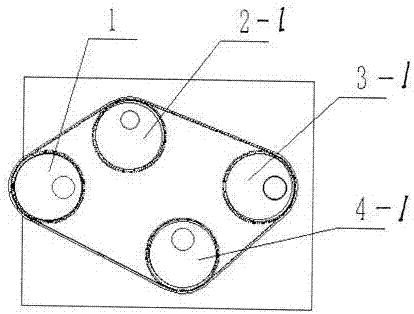

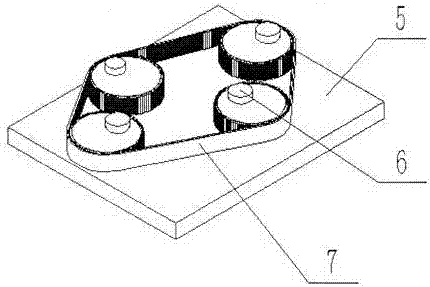

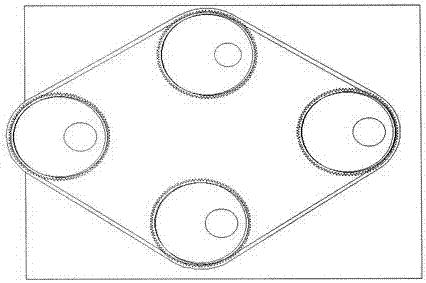

[0008] The embodiment is described in detail in conjunction with the above drawings. The eccentric shafts 6 are respectively arranged on the mounting plate and fastened by set screws. The eccentric 1, eccentric 2-1, eccentric 3-1, and eccentric 4-1 respectively correspond to the eccentric The axles are assembled and connected by a synchronous belt 7 to form an oblique quadrilateral eccentric wheel mechanism. Furthermore, four eccentric wheels are connected to the eccentric wheel shaft 6 through bearings, and the teeth on the belt surface of the synchronous belt are in phase with the teeth on the eccentric wheel. Mesh, the eccentric direction of the eccentric shaft on the eccentric wheel and the eccentric wheel on the diagonal line is consistent, the size of the four eccentric wheels is the same, and the power mechanism is a motor.

[0009] If the eccentric wheel shaft is subjected to clockwise rotation force, it will drive the eccentric wheel 4-1 to rotate clockwise, and the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com