Earthquake disaster gas pipeline shutoff valve

A technology for gas pipelines and shut-off valves, applied in valve details, safety valves, balance valves, etc., can solve the problems of complex shut-off valves, inconvenient maintenance and maintenance, and high manufacturing costs

Active Publication Date: 2017-07-21

山东酷品智能科技有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, the closed valves for mechanical earthquake disaster gas pipelines that have been applied for or authorized are very complicated, with high manufacturing costs and inconvenient repair and maintenance.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0009] SUMMARY OF THE INVENTION The specific embodiments of the present invention have been described in detail, and will not be repeated here.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

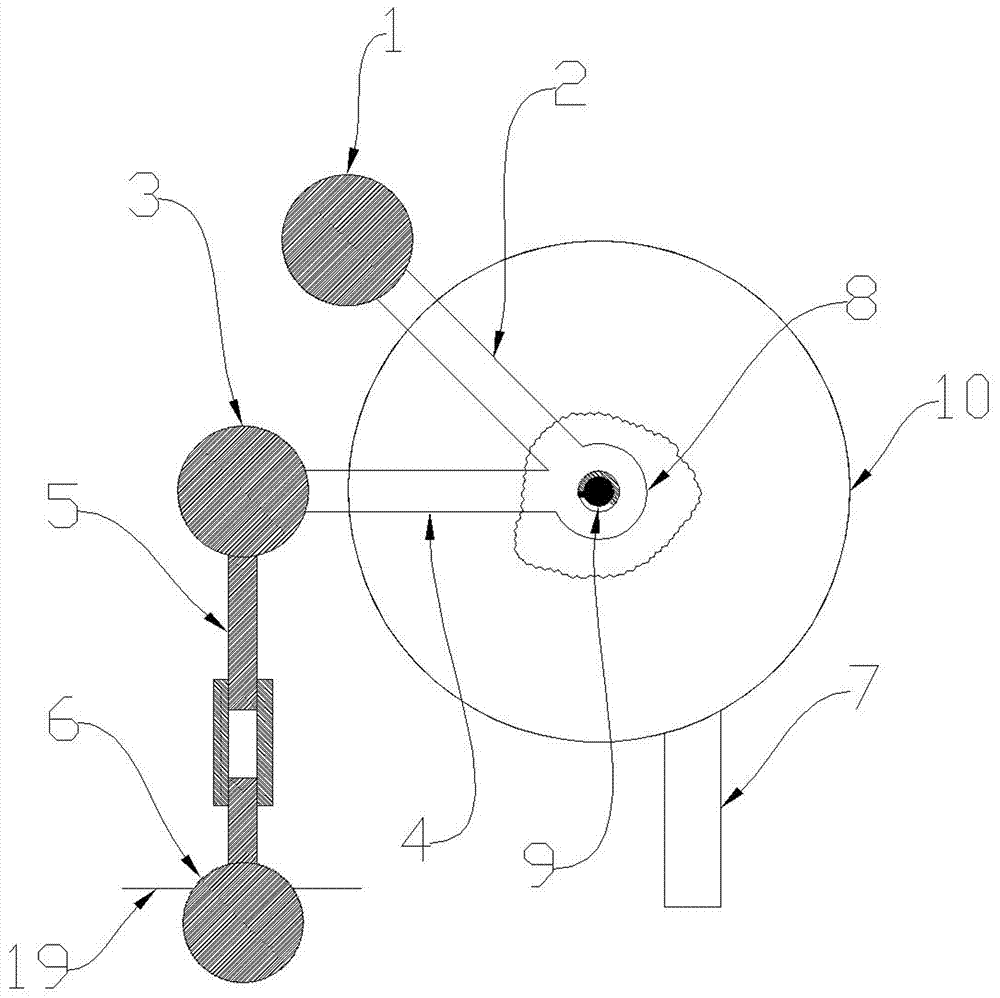

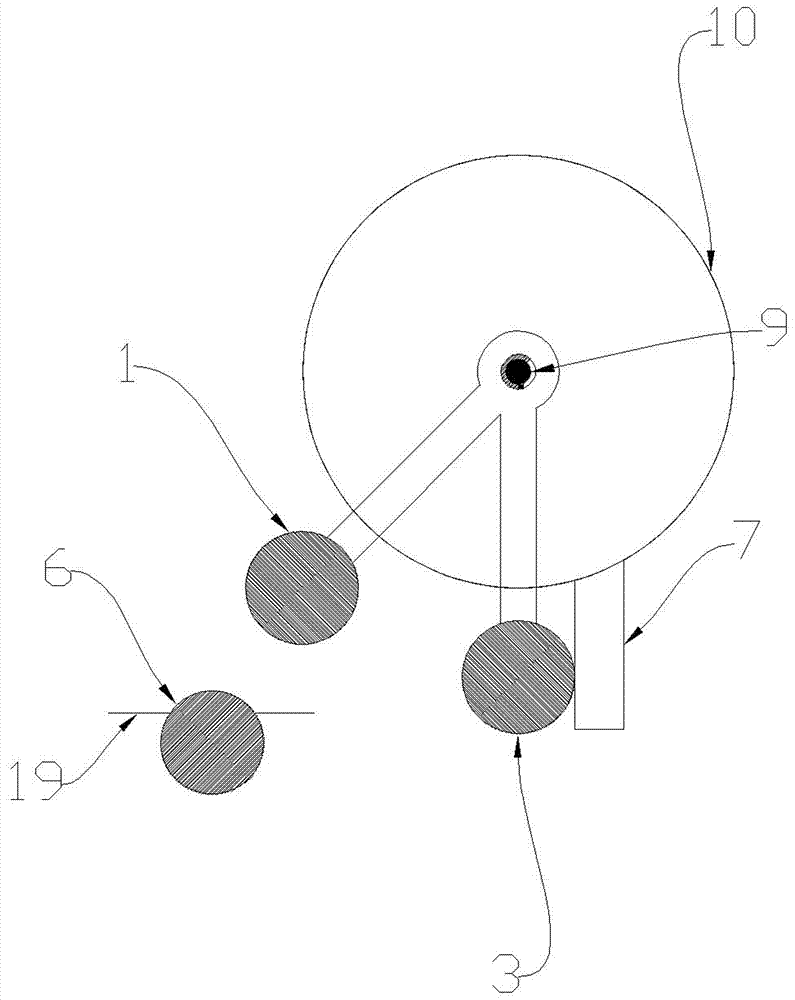

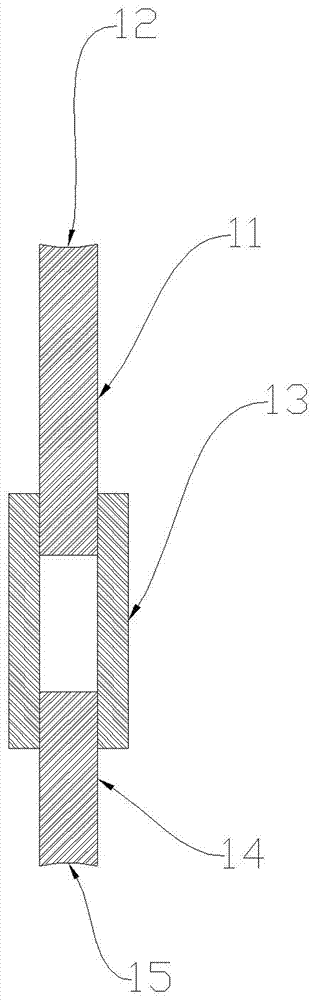

The invention provides an earthquake disaster gas pipeline shutoff valve. The earthquake disaster gas pipeline shutoff valve is mainly used for shutting off a gas pipeline valve body when an earthquake disaster occurs, is simple in structure, low in manufacturing cost and convenient to repair and maintain and is mainly composed of an upper gravity ball, a connecting rod A, a lower gravity ball, a connecting rod B, an ejector rod, a fixed ball, a baffle, a shaft sleeve, a butterfly valve rotary shaft and a butterfly valve body. The main working principle of the earthquake disaster gas pipeline shutoff valve is that the ejector rod is firstly mounted to enable a lower groove of the ejector rod to abut against the upper spherical surface of the fixed ball and meanwhile to enable an upper groove of the ejector rod to abut against the lower spherical surface of the fixed ball; when an earthquake occurs, the ejector rod can only fall towards the ground; the lower gravity ball counterclockwise rotates due the gravity effect and stops rotating after the spherical surfaces of the lower gravity ball collide the baffle; the butterfly valve body is just closed; the lower gravity ball can have certain clockwise resilience after colliding the baffle; and since a dead section exists, the resilience cannot drive the butterfly valve rotary shaft of the butterfly valve body to rotate, and closing of the butterfly valve body is not affected.

Description

Technical field [0001] The invention is mainly used for closing gas pipeline valves when earthquake disasters occur. Background technique [0002] At present, the mechanical shut-off valves for gas pipelines related to earthquake disasters that have been applied for or have been authorized are very complicated, high manufacturing costs, and inconvenient maintenance and maintenance. Summary of the invention [0003] The present invention overcomes the above-mentioned defects. It has simple structure, low manufacturing cost, convenient repair and maintenance. It is mainly composed of upper gravity ball (1), connecting rod A (2), lower gravity ball (3), and connecting rod B (4). , Mandrel (5), fixed ball (6), baffle (7), shaft sleeve (8), butterfly valve shaft (9), butterfly valve (10); the upper end of connecting rod A (2) and the gravity ball (1) ) Fixed, the lower end of connecting rod A (2) is fixed to the shaft sleeve (8), the left end of connecting rod B (4) is fixed to the lo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16K17/36F16K35/00

CPCF16K17/363F16K35/00

Inventor 彭宝安

Owner 山东酷品智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com