Lens and lens group for plug-in LED lamp beads

A technology of LED lamp beads and lens groups, which is applied to the components of lighting devices, lighting and heating equipment, lighting devices, etc., can solve the problem of failure to meet road lighting design standards, effective application, and secondary light distribution of lamps and lanterns and other issues, to achieve the effect of reducing artificial cleaning operations, low manufacturing cost, and beneficial to light mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

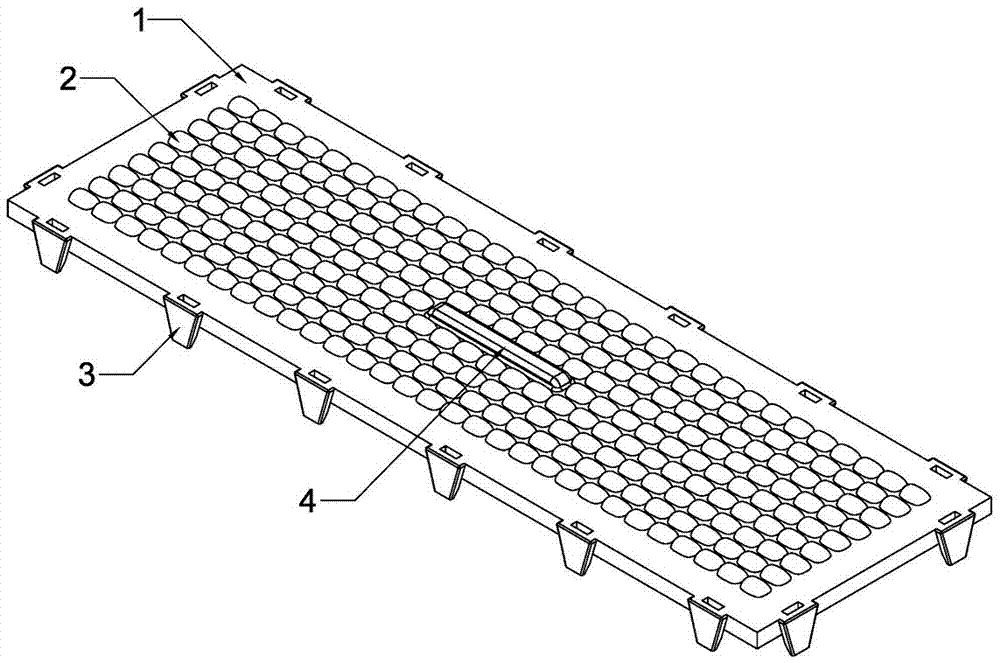

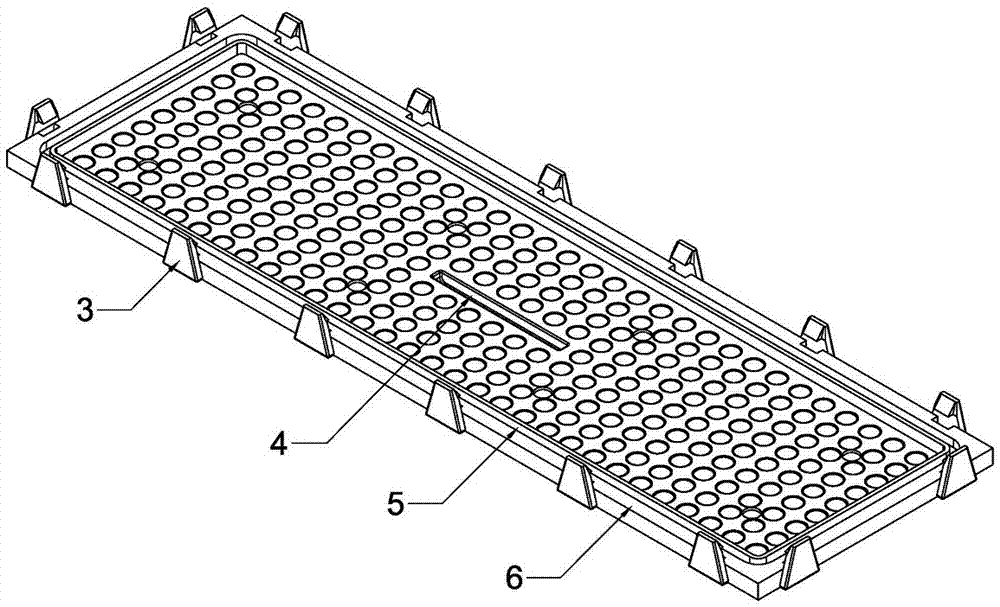

[0029] Attached Figure 1 The device shown realizes plug-in LED bead lens and lens group.

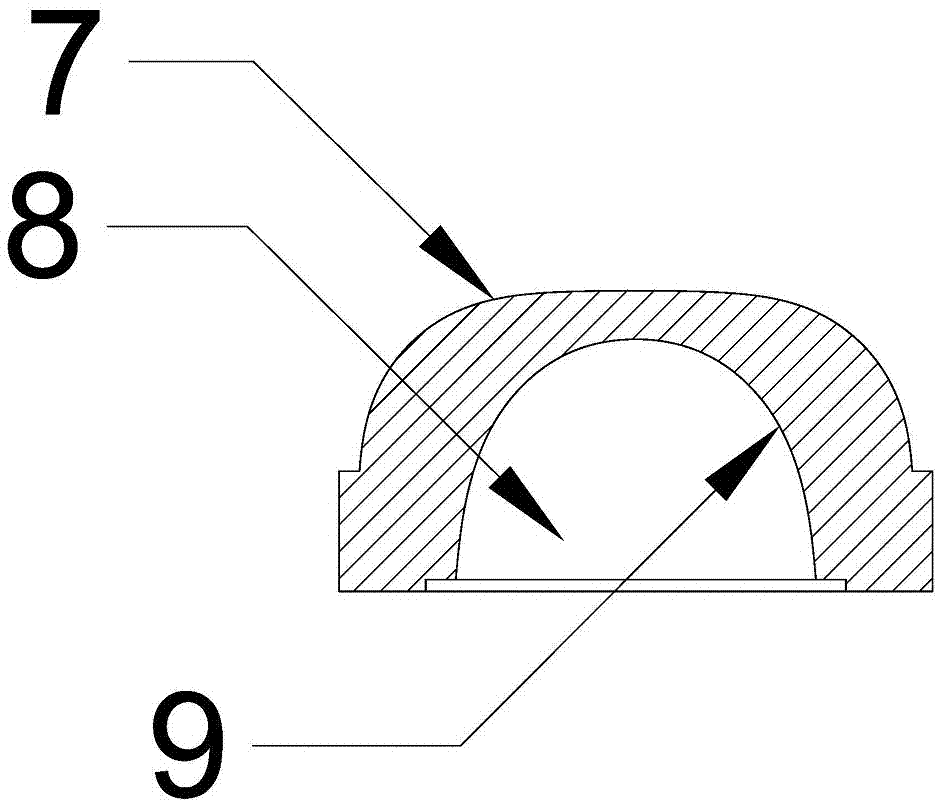

[0030] For the plug-in LED lamp bead lens and lens group, as attached Figure 1 As shown, the optical grade polycarbonate is used as the raw material, and the injection molding process is adopted to form a lens group of 264 single lenses. The lens group includes a waterproof ring groove, a cable accommodation groove, a mounting surface, and an assembly buckle; Insert the waterproof ring into the waterproof ring groove, press down the lens group so that the hook catches the radiator, and the secondary optical design effect can be realized.

[0031] This embodiment realizes the plug-in LED lamp bead lens and lens group device through a series of measures. Compared with other plug-in LED lamp bead lens technologies, it has higher matching adaptability, light distribution accuracy, lower cost, and is more conducive to manufacture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com