Heat storage type air source heat pump direct condensation type floor heating system

An air source heat pump and direct-condensing technology, applied in the field of radiant heating, can solve the problems of frequent defrosting, short range of use seasons, and low defrosting efficiency, so as to improve energy efficiency ratio, slow down frosting speed, and improve defrosting efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

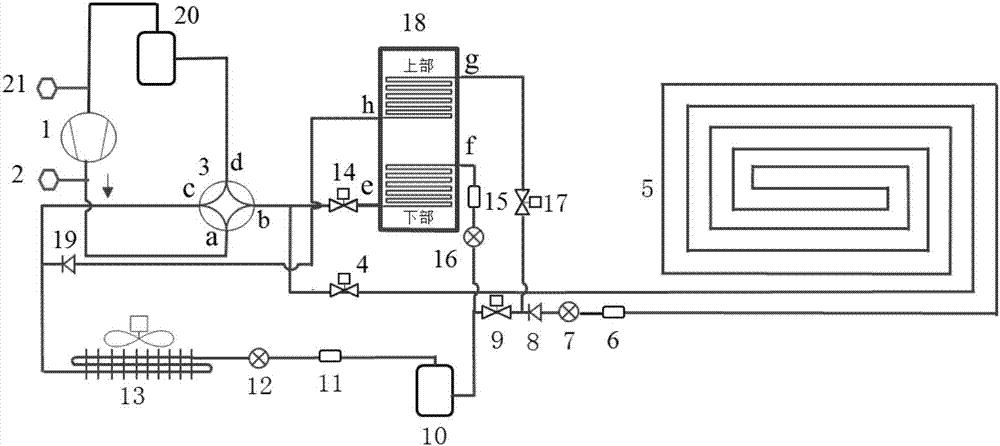

[0016] Such as figure 1 Shown is the principle diagram of the present invention, a thermal storage type air source heat pump direct-condensing floor heating system, the connection mode of each component of the system is: the compressor 1 is connected to the high-voltage protection switch 2 through the pipeline, and the high-voltage protection switch 2 The a port of the four-way valve 3 is connected through a pipeline, and the b port of the four-way valve 3 is respectively connected with the solenoid valve 4 and the solenoid valve 14 through the pipeline. First, the solenoid valve 4 is connected to the inlet of the floor heating coil 5 through a pipeline, the outlet of the floor heating coil 5 is connected to the dry filter 6, the dry filter 6 is connected to the electronic expansion valve 7 through the pipeline, and the electronic expansion valve 7 passes through The pipeline is connected to the shut-off valve 8, and the shut-off valve 8 is respectively connected to the soleno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com