Cooling box for food processing

A technology of food processing and cooling box, applied in the field of food processing, can solve the problems of slow frosting speed, blade breakage, increase blade brittleness, etc., and achieve the effect of reducing speed and preventing water overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

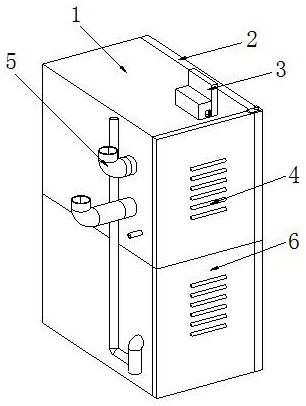

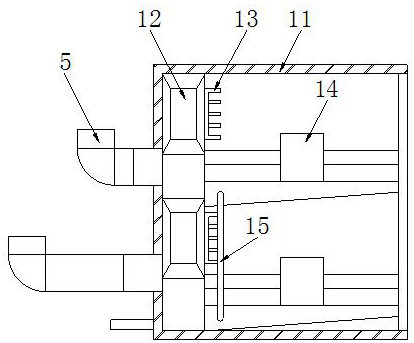

[0022] as attached figure 1 To attach Figure 5 Shown:

[0023] The present invention is a cooling box for food processing, its structure includes a cooling storage box 1, a box door 2, a control panel 3, a cooling groove 4, a copper pipe 5, and a cooling host 6, and the right end surface of the cooling storage box 1 is provided with The box door 2, the upper end of the cooling storage box 1 is provided with a control panel 3, the heat dissipation groove 4 is embedded in the outer surface of the cooling storage box 1, the copper pipe 5 is embedded and installed on the left end surface of the cooling storage box 1, and the cooling The lower end of the placement box 1 is fixed to the top of the cooling host 6. The cooling placement box 1 includes a box body 11, a refrigerator 12, a hydrophilic aluminum sheet 13, a water removal mechanism 14, and a connecting water pipe 15. The inner wall of the box body 11 is fixed and installed There is a refrigerator 12, the refrigerator 12 ...

Embodiment 2

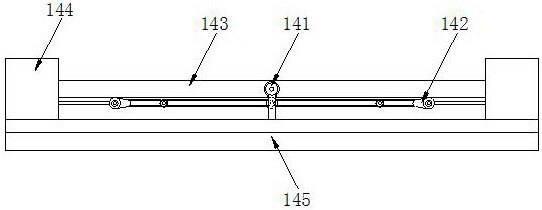

[0030] as attached Image 6 to attach Figure 7 Shown:

[0031] Wherein, the placement plate 143 includes a plate body 43a, a placement groove 43b, a drip opening 43c, a telescopic hose 43d, and an air injection mechanism 43e. Groove 43b, the lower end of the placement groove 43b is connected to the upper end of the drip port 43c, the drip port 43c is embedded inside the lower end of the plate body 43a, the top of the telescopic hose 43d is fixed to the lower surface of the plate body 43a, the telescopic soft The top of the pipe 43d is connected with the air injection mechanism 43e, and the air injection mechanism 43e is embedded inside the upper surface of the plate body 43a. The placement groove 43b is in an arc-shaped groove structure, and there are nine of them, which is beneficial to separate and place the leafy vegetables , reduce the collision and extrusion between leafy vegetables, improve the effect of placing and fixing leafy vegetables at the same time, and avoid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com