Aperture measurement tool

A technology for measuring tools and apertures, applied in the field of measuring tools, can solve the problems of inability to measure, long length, etc., and achieve the effect of convenient and fast measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

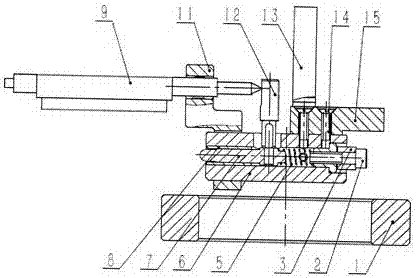

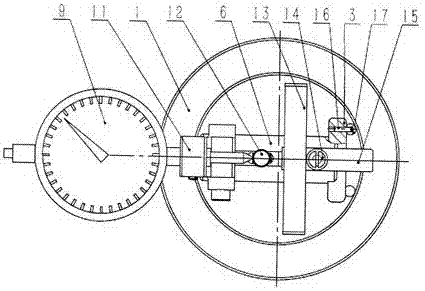

[0007] The present invention is in order to solve the above-mentioned defect that prior art exists, the technical scheme of the present invention, such as Figure 1-2 As shown, the base body 6 is provided with a transverse hole slidingly matched with the measuring shaft 7. A bushing 8 is provided in the transverse hole. The measuring shafts are left and right measuring shafts. The left and right measuring shafts A spring 5 is arranged between the shafts, and the connecting plate 3 is connected with the right measuring shaft by a screw 2. A pin shaft 16 is respectively provided at the front and rear of the outside of the connecting plate, and a steel ball 17 is provided at the end of the pin shaft, and the left measuring shaft The outer end surface of the base body is a hemispherical surface. In order to ensure the accuracy of the measurement, the plane where the center of the two steel balls of the above connecting plate and the center of the spherical surface of the outer end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com