Method for manufacturing implantable micro-biosensor

A manufacturing method and micro-biological technology, which can be applied in sensors, medical science, catheters, etc., can solve the problems of high infection risk, large implantation wound, and significant pain, so as to reduce the influence of interfering substances, measure accuracy, and meet the requirements of the manufacturing process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

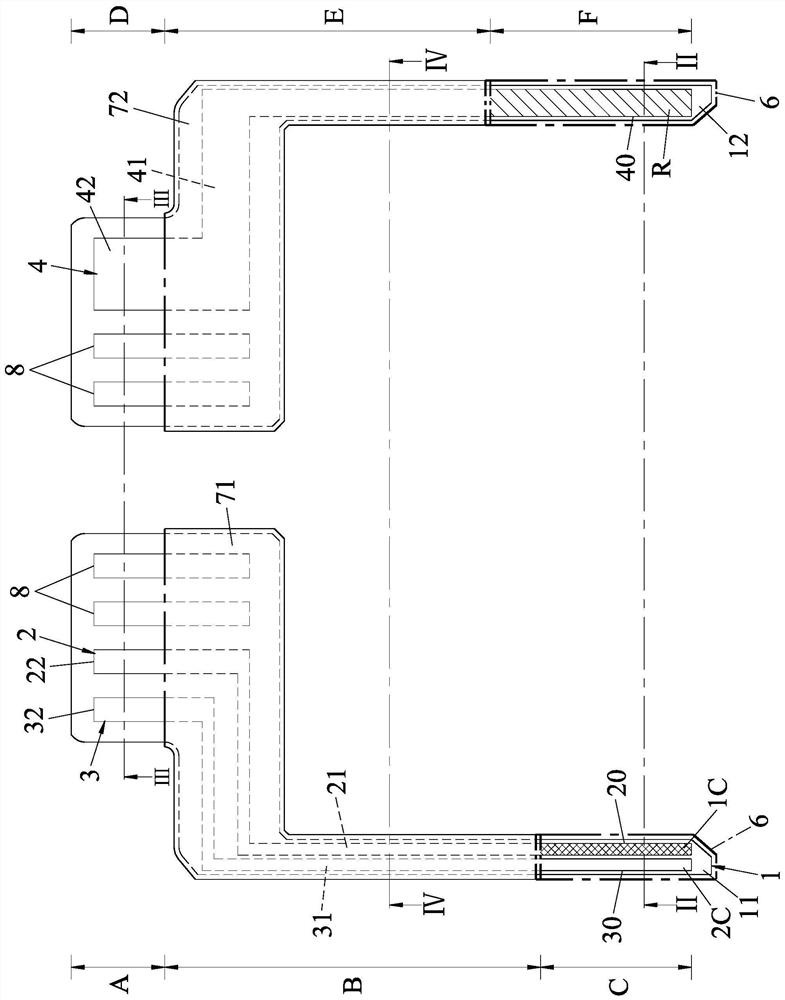

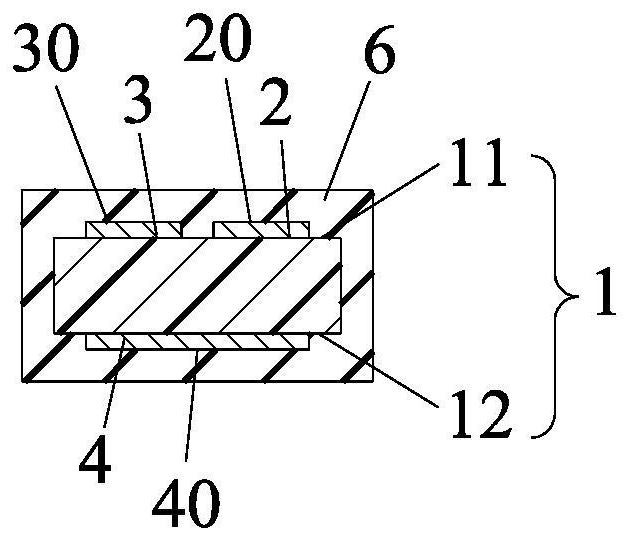

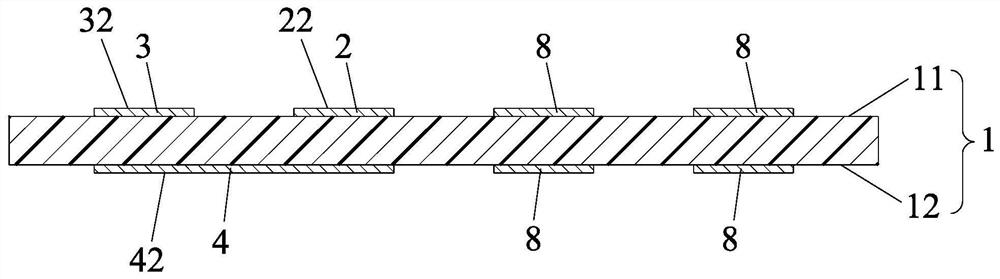

[0097] figure 1 It is a schematic structural diagram of the implantable miniature biosensor of Example 1 of the present invention. In Embodiment 1, the first surface of the implanted miniature biosensor is divided into a first signal output area A for connecting with a transmitter (not shown in the figure), and an area A for measuring the analyte in the organism. A first sensing region C for a physiological parameter (such as concentration, glucose concentration in embodiment 1) and a first signal connection region B connecting the first signal output region A and the first sensing region C. The implantable miniature biosensor is partially implanted under the skin surface of the organism in a manner perpendicular to the skin surface of the organism and has an implant end, and the implant end at least includes the first sensing region c. Specifically, the length of the implant end must at least reach the dermis and measure the depth of glucose in the interstitial fluid, and i...

Embodiment 2

[0131] Please refer to Figure 16 to Figure 19 , the structure of the implantable miniature biosensor of embodiment 2 is roughly the same as that of embodiment 1, the difference is that: in order to effectively reduce the interference of the interfering substance to the measurement of the physiological signal within an error range, the second embodiment of embodiment 2 The two sensing sections 30 are adjacent to at least three sides of the first sensing section 20 with a gap, that is, the second sensing section 30 surrounds at least three sides of the first sensing section 20 with the gap. side. Preferably, the gap is not greater than 0.2mm, but more preferably the gap ranges from 0.02mm to 0.05mm. More specifically, one side of the second sensing section 30 extends along the periphery of the first sensing section 20 and is bent to surround at least three sides of the first sensing section 20 in a U shape. At this time, if Figure 20 As shown, the second sensing section 30 ...

Embodiment 3

[0135] Such as Figure 24 to Figure 26 As shown, the structure of the implantable micro-biosensor of embodiment 3 is substantially the same as that of embodiment 2, the difference is that the implantable micro-biosensor of embodiment 3 also includes a pair of electrodes 4 spaced apart from each other. The reference electrode 9 on the second surface 12, and the surface of the reference electrode 9 contains at least silver / silver halide R. In order to provide sufficient capacity and adjust the amount of silver / silver halide, the area of the counter electrode 4 is larger than that of the reference electrode 9 .

[0136] To elaborate further, such as Figure 24 As shown, the pair of electrodes 4 is specifically arranged on the second surface 12 of the substrate 1 and is designed in the second sensing region F of the implanted end of the implantable micro biosensor to have an electrode along the implantation direction. (that is, the direction perpendicular to the skin surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com