Preparation method of simulated tobacco shreds and method for analyzing and researching maillard reaction in cigarette tobacco shred drying procedure by using simulated tobacco shreds

A Maillard reaction, analysis and research technology, applied in the preparation of simulated cut tobacco and the field of Maillard reaction, can solve problems such as research interference and research complication, and achieve the effect of avoiding interference, accurate research and more targeted effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

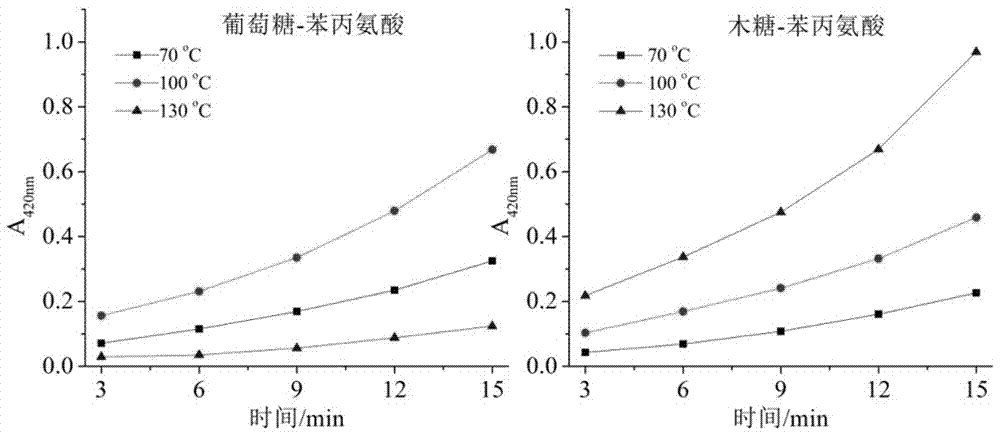

[0029] Using glucose, xylose and phenylalanine as raw materials, prepare 1000 mL of glucose-phenylalanine solution and xylose with reducing sugar concentration of 0.05mol / L according to the ratio of reducing sugar and amino acid molar ratio of 1:1 - phenylalanine solution with K 2 HPO 4 or KH 2 PO 4 Buffer to adjust its pH to 5.5. Take 100 g of qualitative filter paper and soak them evenly in 1000 mL of glucose-phenylalanine solution and xylose-phenylalanine solution for 2 h, then take out the filter paper and spread it out to dry, and place it at a temperature of (22±1) o C and relative humidity (60±2)% in a constant temperature and humidity environment for 48 hours, and then shredded with a tobacco leaf cutter to obtain two kinds of simulated shredded tobacco. Use a throat sprayer to adjust the moisture content of the simulated cut tobacco to about 20%. Then put each group of 2 g cut tobacco at 70 o C. 100 o C and 130 o C Dries silk for 3 min, 6 min, 9 min, 12 min an...

Embodiment 2

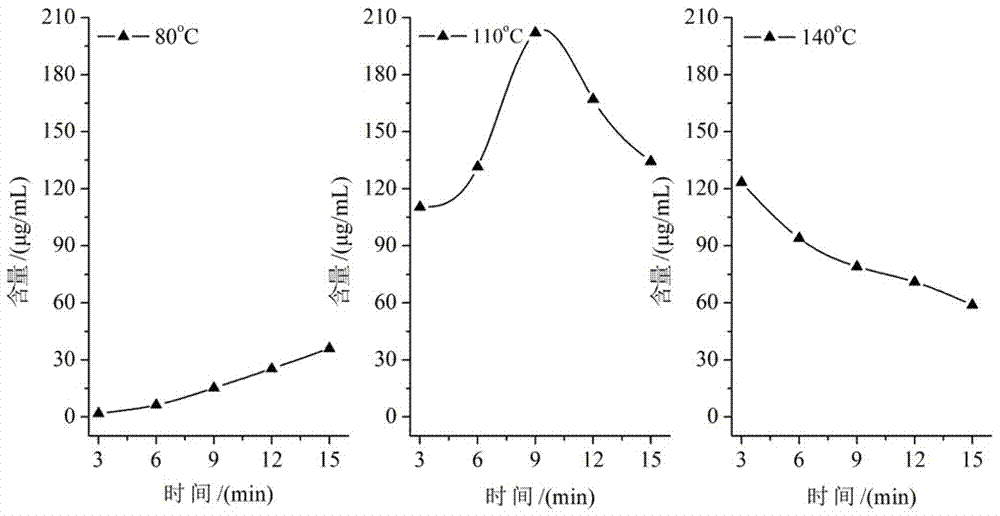

[0031] Prepare 1000 mL of a solution with a fructose concentration of 0.1 mol / L according to the molar ratio of fructose and proline at a ratio of 1:1, and use Na 2 HPO 4 or NaH 2 PO 4 Adjust the pH of the buffer solution to 7.4 to obtain a fructose-proline solution. Take 100 g of qualitative filter paper and soak it in 1000 mL of fructose-proline solution evenly for 1 h, then take out the filter paper and spread it out to dry, and place it at a temperature (22 ± 1) o C and relative humidity (60±2)% in a constant temperature and humidity environment for 48 hours, and then shred it with a tobacco leaf cutter to obtain simulated shredded tobacco. Use a throat sprayer to adjust the moisture content of the simulated cut tobacco to about 20%. Then each group of 2 g simulated tobacco at 80 o C. 110 o C and 140 o C Dries silk for 3 min, 6 min, 9 min, 12 min and 15 min respectively. The shredded tobacco after drying was shaken and extracted with 50 mL of distilled water for 1 ...

Embodiment 3

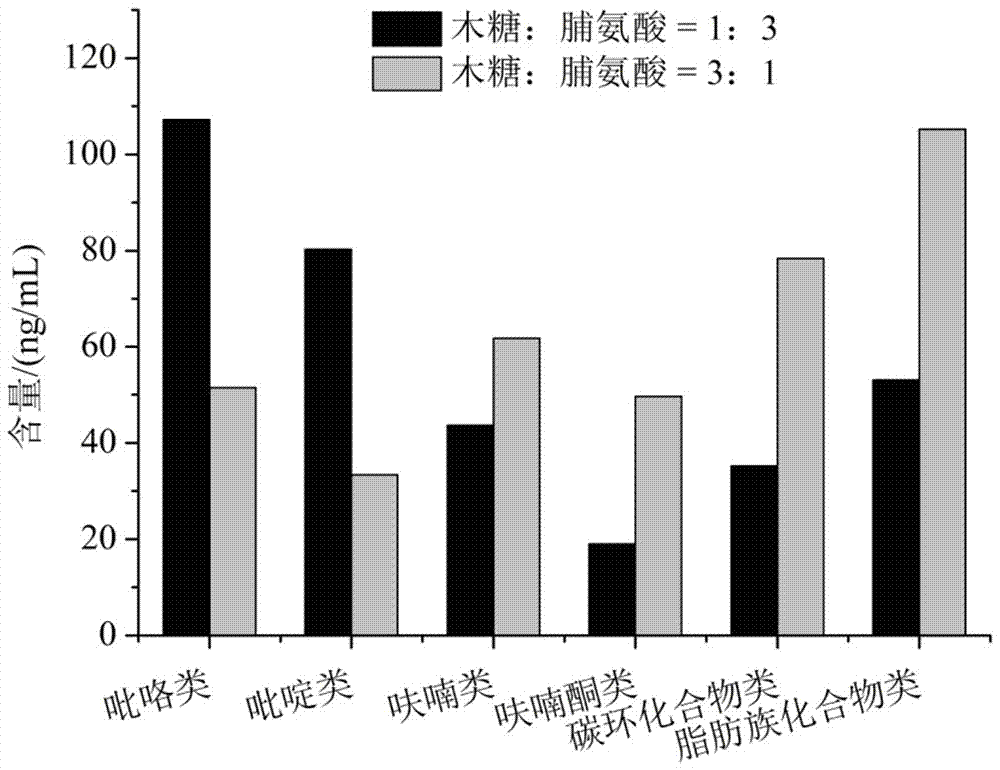

[0037] According to the ratio of xylose and proline molar ratio of 3:1 or 1:3, prepare 1000 mL solution with xylose concentration of 0.1 mol / L and 1000 mL solution with proline concentration of 0.1 mol / L, and use K 2 HPO 4 and KH 2 PO 4 The pH of the buffer was adjusted to 9.0 to obtain two xylose-proline solutions. Take 100 g of qualitative filter paper and soak them evenly in these two xylose-proline solutions for 1 h, then take out the filter paper and spread it out to dry, and place it at a temperature of (22±1) o C and relative humidity (60±2)% in a constant temperature and humidity environment for 48 hours, and then shred it with a tobacco leaf cutter to obtain simulated shredded tobacco. Use a throat sprayer to adjust the moisture content of the simulated cut tobacco to about 20%. Take 10 g simulated shredded tobacco at 120 o C and dry silk for 10 min. After drying, place it in a conical flask, add 50 ml CH 2 Cl 2 , and then add 10 μL of phenethyl acetate (CH 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com