High-voltage insulating overhead ground wire short-coupling device

An overhead ground wire and high-voltage insulation technology, which is applied in the direction of overhead lines/cable equipment, winding connectors, etc., can solve problems such as deficiencies, and achieve the effects of reasonable structure, firm fixation, and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

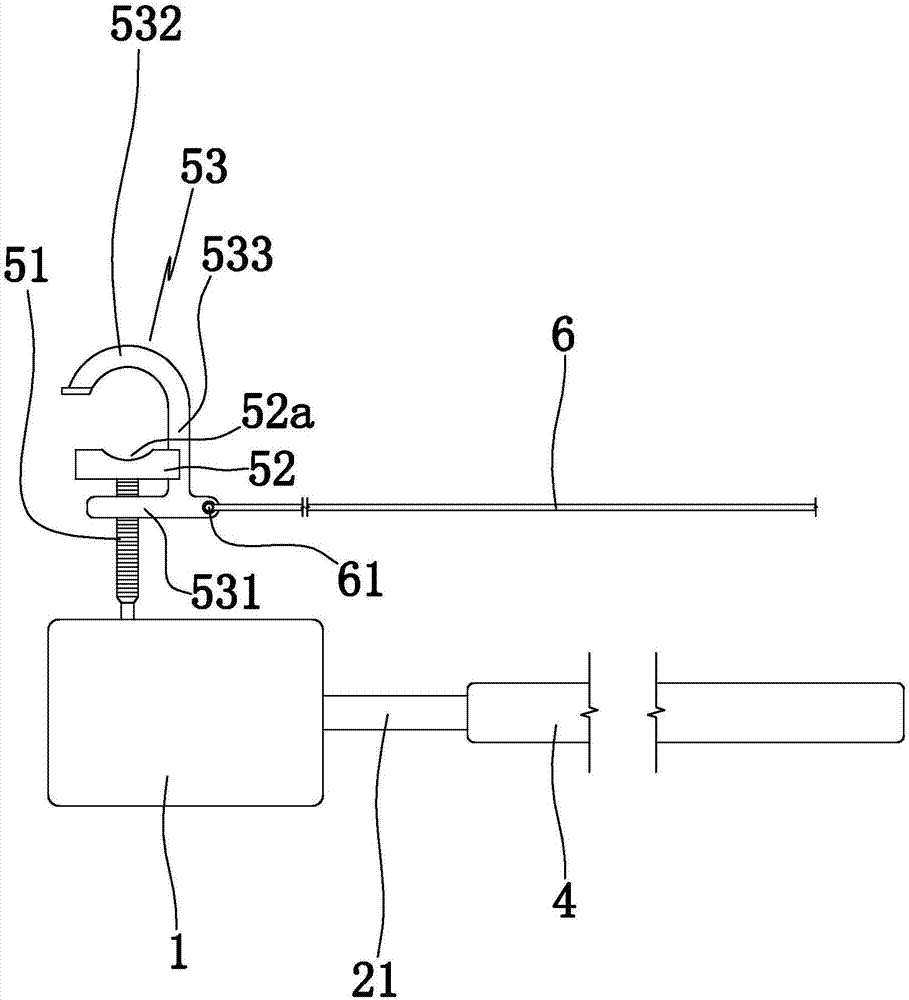

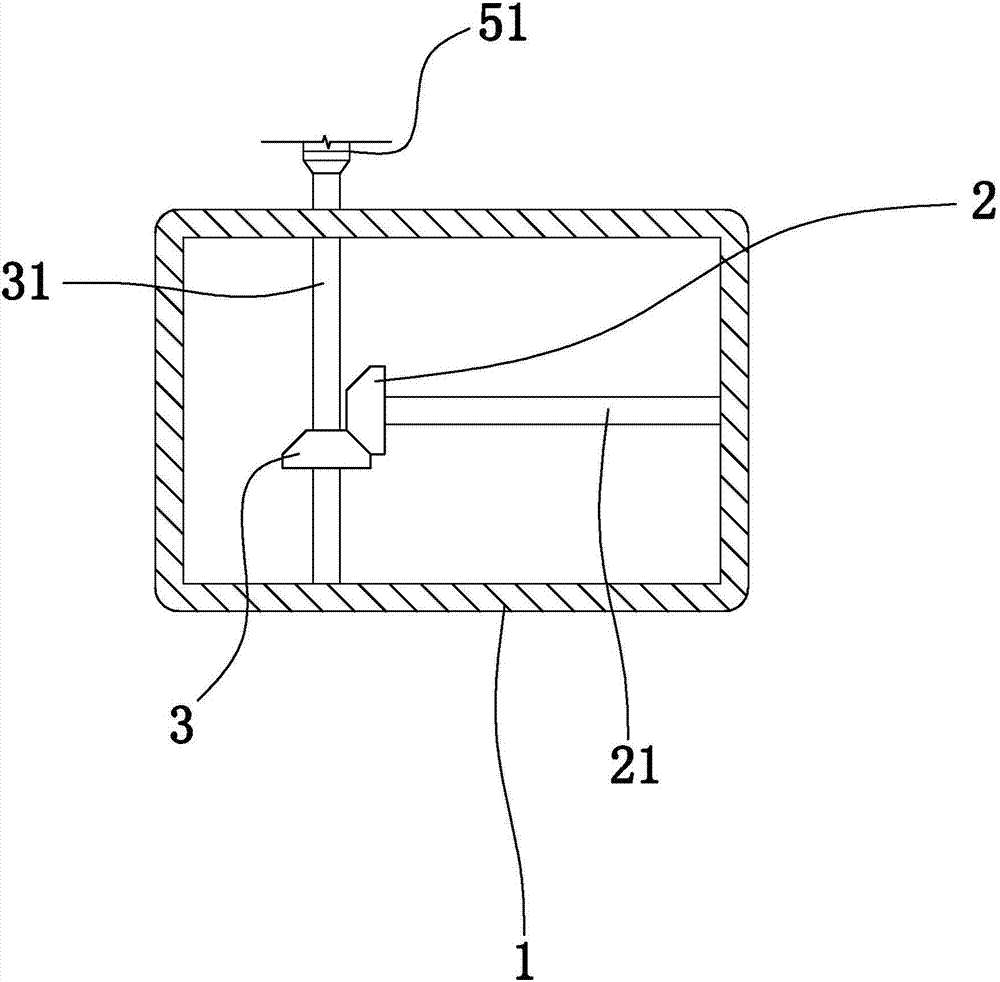

[0021] Embodiment 1: as Figure 1 to Figure 2 As shown in , a high-voltage insulating overhead ground wire short-circuit device includes a box body 1, a driving bevel gear 2, a driven bevel gear 3, an auxiliary transmission rod 31 coaxially connected with the driven bevel gear, and is used to drive the driving bevel gear The rotary handle 4 rotated by the gear and the clamping structure arranged on the box body, the rotary handle bar is coaxially connected with the driving bevel gear, the driving bevel gear meshes with the driven bevel gear, and the auxiliary transmission rod is connected with the box body in rotation, The clamping structure includes a vertical screw 51 coaxially connected with the auxiliary transmission rod, a clamping seat 52 arranged on the top of the vertical screw, and a metal hook 53 arranged on the vertical screw. The metal hook includes a hook seat that is threadedly matched with the vertical screw 531, the hook 532 above the clamping seat and the conn...

Embodiment 2

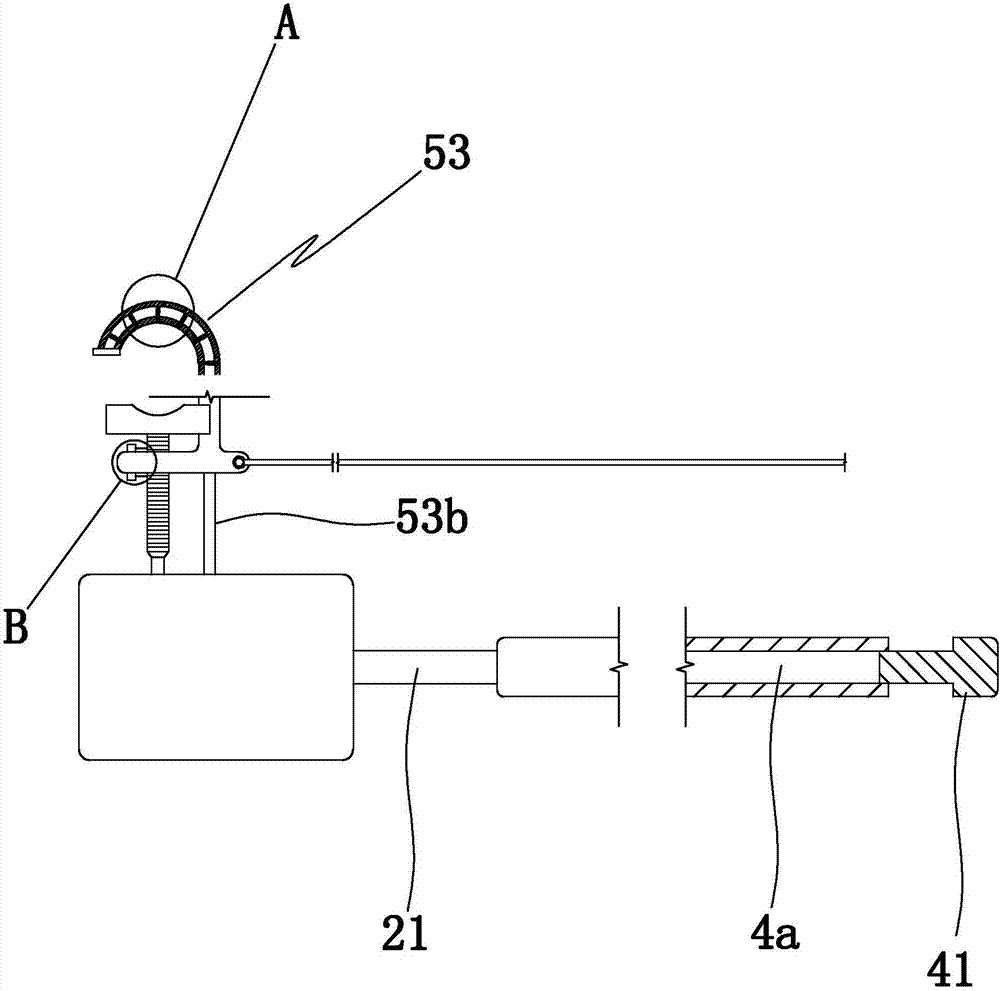

[0026] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 3 to Figure 6 As shown in , the metal hook is provided with a hook inner oil passage 53a and a plurality of extruding rods 71, the hook inner oil passage communicates with the inside of the box through the oil pipe 53b, and the main transmission rod is provided with a connection with the inside of the box. Rod inner oil passage 21a, the main regulating oil passage 4a connected with the rod inner oil passage is provided on the rotary handle rod, and the end of the rotary handle rod away from the box is provided with an oil pressure screw 41 threadedly matched with the rotary handle rod, and the oil pressure screw One end is outside the main regulating oil passage, and the other end of the oil pressure screw extends into the main regulating oil passage. The extrusion rod and the metal hook slide and seal. The inner end of the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com