Buried type tool cabinet

A tool cabinet and underground technology, applied in the field of machinery and equipment, can solve the problems of physical exertion, inconvenient tool handling, etc., and achieve the effects of saving time, convenient access to tools and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

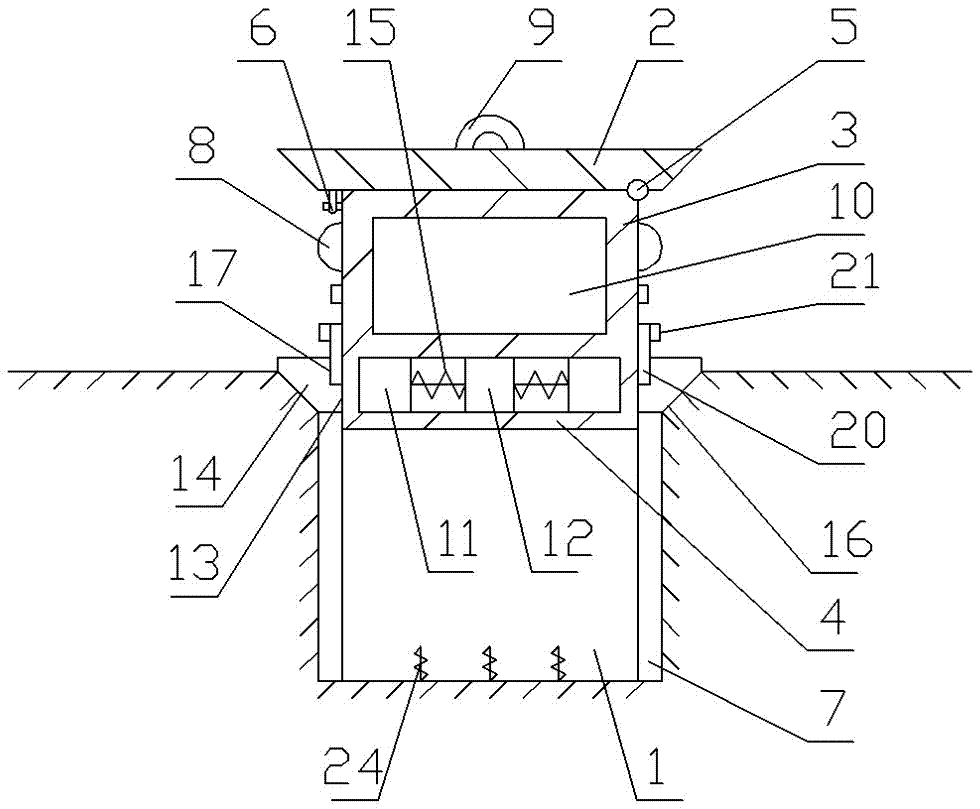

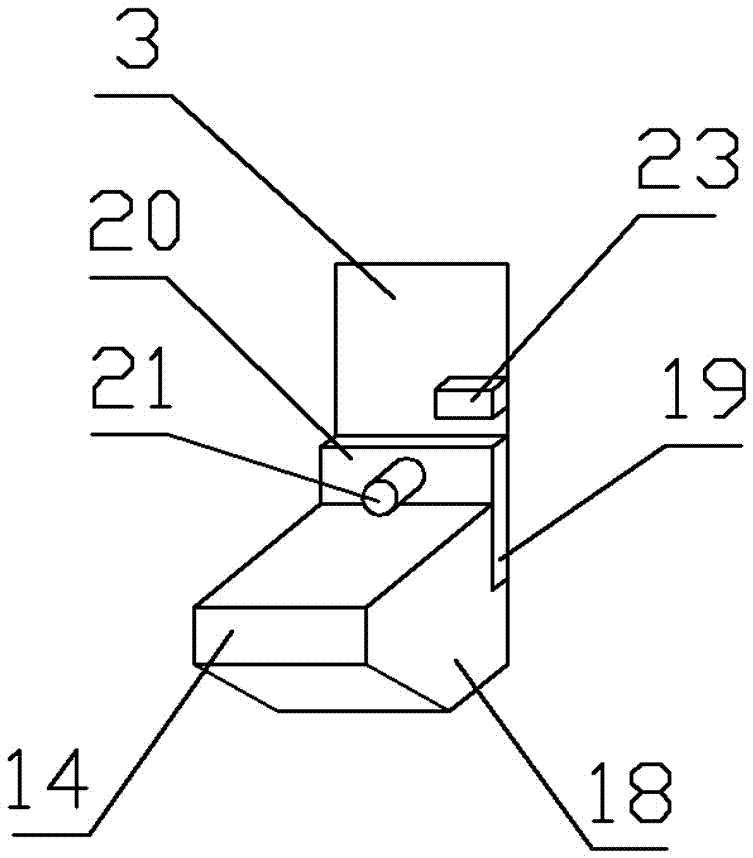

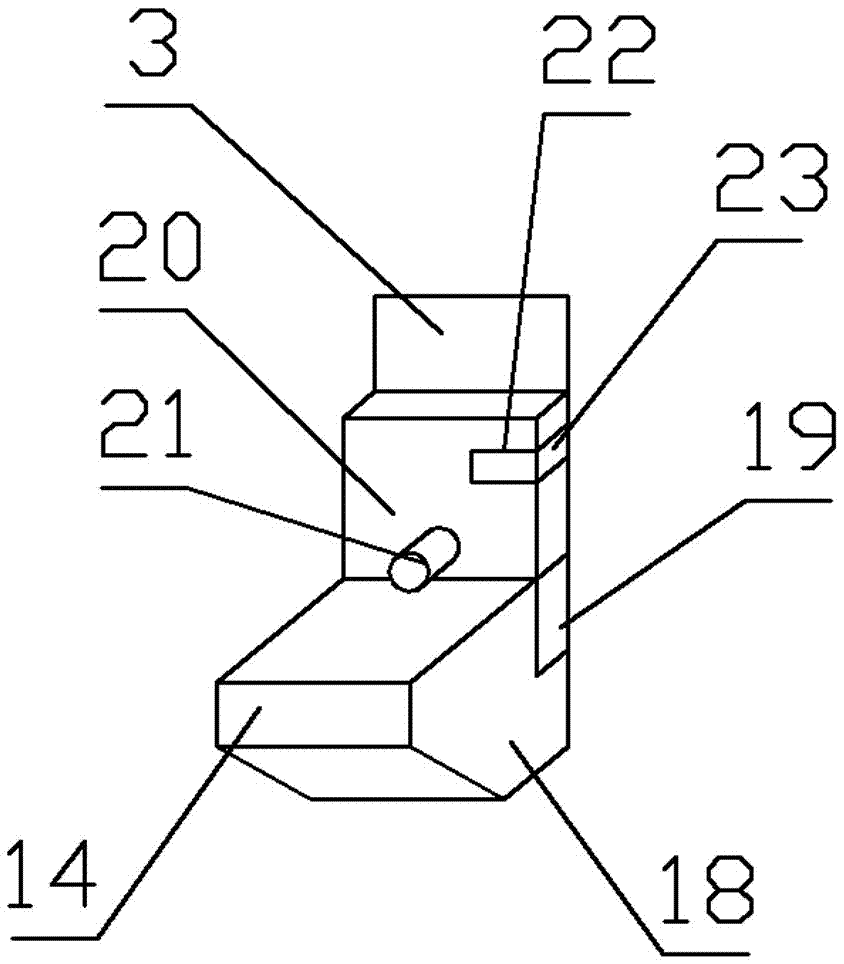

[0028] Such as Figure 1 to Figure 3 As shown, the bottom of the top cover 2 and the top of the side plate 3 are rotatably connected by a hinge 5, and on the side opposite to the hinge 5, the bottom of the top cover 2 and the top of the side plate 3 are connected by a latch 6; the inner wall of the pit 1 is vertically There are two slide rails 7, and each slide rail 7 is evenly distributed in the center of the pit 1; the outer wall of the side plate 3 is provided with pulleys 8, the number of pulleys 8 and the slide rails 7 are equal and the positions correspond to each other; the top of the top cover 2 is provided with handle9.

[0029] From top to bottom in the vertical direction, the interior of the cabinet is divided into a tool compartment 10 and a bottom compartment 11; a column 12 is fixed inside the bottom compartment 11, and the central axis of the column 12 corresponds to the center of the bottom plate 4; the side wall of the bottom compartment 11 is provided with 3...

Embodiment 2

[0035] Such as Figure 1 to Figure 3 As shown, the bottom of the top cover 2 and the top of the side plate 3 are rotatably connected by a hinge 5, and on the side opposite to the hinge 5, the bottom of the top cover 2 and the top of the side plate 3 are connected by a latch 6; the inner wall of the pit 1 is vertically There are two slide rails 7, and each slide rail 7 is evenly distributed in the center of the pit 1; the outer wall of the side plate 3 is provided with pulleys 8, the number of pulleys 8 and the slide rails 7 are equal and the positions correspond to each other; the top of the top cover 2 is provided with handle9.

[0036] From top to bottom in the vertical direction, the interior of the cabinet is divided into a tool compartment 10 and a bottom compartment 11; a column 12 is fixed inside the bottom compartment 11, and the central axis of the column 12 corresponds to the center of the bottom plate 4; the side wall of the bottom compartment 11 is provided with 3...

Embodiment 3

[0041] Such as Figure 1 to Figure 3 As shown, the bottom of the top cover 2 and the top of the side plate 3 are rotatably connected by a hinge 5, and on the side opposite to the hinge 5, the bottom of the top cover 2 and the top of the side plate 3 are connected by a latch 6; the inner wall of the pit 1 is vertically There are two slide rails 7, and each slide rail 7 is evenly distributed in the center of the pit 1; the outer wall of the side plate 3 is provided with pulleys 8, the number of pulleys 8 and the slide rails 7 are equal and the positions correspond to each other; the top of the top cover 2 is provided with handle9.

[0042] From top to bottom in the vertical direction, the interior of the cabinet is divided into a tool compartment 10 and a bottom compartment 11; a column 12 is fixed inside the bottom compartment 11, and the central axis of the column 12 corresponds to the center of the bottom plate 4; the side wall of the bottom compartment 11 is provided with 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com