Self-propelled drill hole repairing device and method

A self-advancing, in-drilling technology, which is used in wellbore drilling drives, drilling equipment, and earth-moving drilling, etc., can solve problems such as blockage, hole collapse, and impact on gas drainage efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

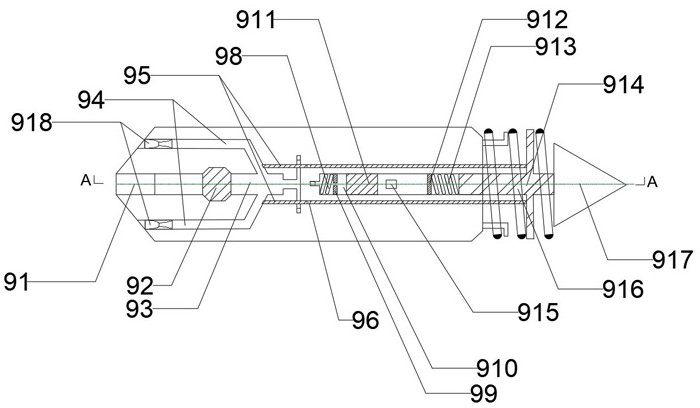

[0028] The head described in the text starts with figure 2 The right side of the center prevails, and the tail is figure 2 Center left.

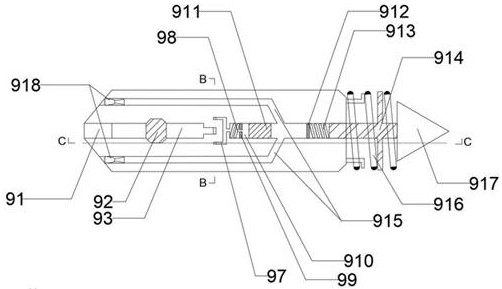

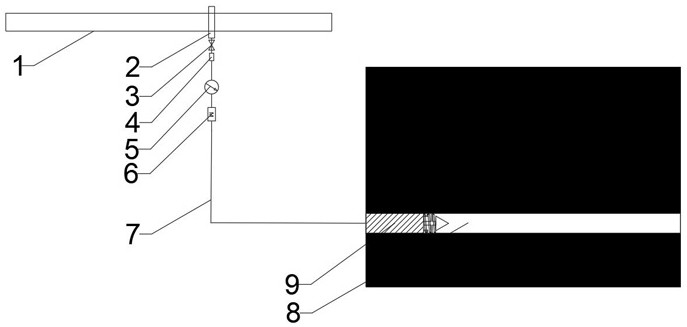

[0029] As shown in the figure, a self-propelled drilling repair device includes a pressure air pipe 1 located in the downhole, and a hose 7 communicating with the pressure air pipe 1 through an adapter 4. The downhole pressure air pipe 1 is provided with Useful wind point flange 2, with a valve 3 on the wind point flange 2, the valve 3 is connected with the adapter 4, the hose 7 at the lower part of the adapter 4 is provided with a pressure gauge 5 and a flow rate 1, the other end of the hose 7 is connected to the tail of the percussion drill 9, the percussion drill 9 is located in the borehole to be repaired, the percussion drill 9 includes a chamber at the tail and a drill at the head , the center of the chamber is provided with an air passage 93 communicating with the hose 7, a check valve 92 is arranged in the air passage 93, and a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com