Preparation method of high purity graphite

A production method and high-purity graphite technology, applied in the production field of ultra-high-purity graphite, can solve the problems of increased total cost, increased production cost, low recovery rate, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

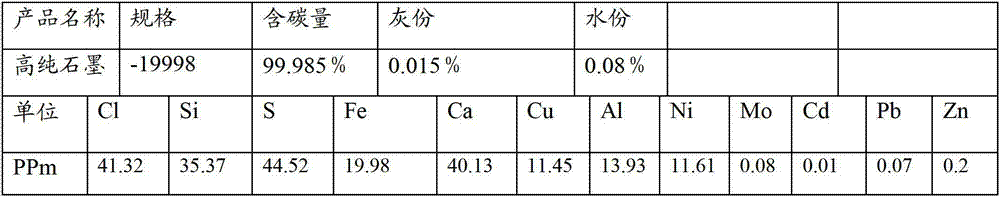

Embodiment 1

[0058] Add 1.6 tons of flake graphite with a specification of 100 mesh and a carbon content of 95% and 800 kilograms of water into a polyethylene plastic tank, and then add 200 kilograms of hydrofluoric acid aqueous solution with a concentration of 47% by weight. 400 kg of 30% hydrochloric acid aqueous solution, first pass in compressed air to make the materials mix evenly, then pass in steam to react for 10 hours, add a large amount of pure water, stir it with an air pump for 10 minutes until it is uniform, put it into the suction filter device, open The Roots vacuum pump performs suction filtration, and when only about 1 / 4 of the water and materials are left in the reaction tank, add pure water into the reaction tank again and stir, and then filter; repeat this 3-5 times until the pure water in the reaction tank is used. pH test paper is measured as neutral. 300 kg of aqueous hydrochloric acid with a concentration of 30% by weight and HNO with a concentration of 30% by weigh...

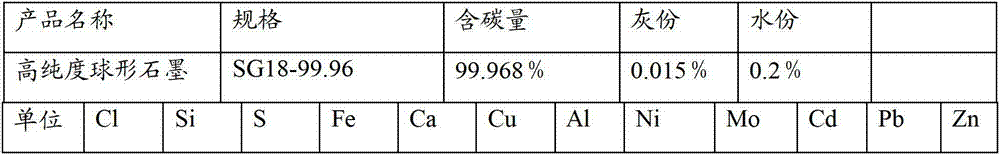

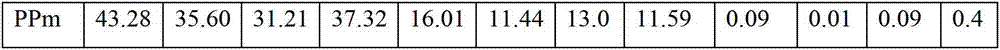

Embodiment 2

[0064] Add 2 tons of spherical graphite materials with a particle size of 18 microns and 1.5 tons of water into a polyethylene plastic tank, add 400 kilograms of hydrofluoric acid aqueous solution with a concentration of 45% by weight, and 200 kilograms of hydrochloric acid aqueous solution with a concentration of 30% by weight. After 12 hours of reaction, add a large amount of pure water, stir evenly and then put it into a polytetrafluoro suction filter device for suction filtration, suction filter until the material and water are 1 / 3 of the original volume, then add pure water for suction filtration, so Repeat 3 to 5 times until the washed water is neutral (with pH test paper), then add 300 kg of hydrochloric acid aqueous solution with a concentration of 30% by weight and HNO with a concentration of 30% by weight 3 100 kilograms of aqueous solution, after reacting for 8 hours, add 18 kilograms of concentrated nitric acid aqueous solution (concentration is 65% by weight) as ox...

Embodiment 3

[0071] Put 1.2 tons of spherical graphite with a particle size of 13 microns and 600 kg of water into a polyethylene plastic tank, add 150 kg of hydrofluoric acid aqueous solution and 250 kg of hydrochloric acid aqueous solution in proportion, react at a temperature of 80-110 for 9 hours, and then add a large amount of Pure water, after mixing evenly, put it into the suction filtration device for suction filtration, add a large amount of pure water again after the suction filtration, and suction filtration 3 to 5 times, until the filtered water is neutral with pH test paper; start the second Secondary reaction: add 600 kg of pure water, then add 300 kg of dilute hydrochloric acid aqueous solution and 100 kg of dilute nitric acid aqueous solution, react for 6 hours and then discharge and wash to obtain high-purity high-purity graphite. The aqueous solutions of the various acids used above have the same concentration as in the previous example.

[0072] According to the GB / T3521...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com