Turnover production line for articles large in surface friction coefficient difference

A technology with surface friction and large differences, applied to impact-sensitive items, types of packaging items, conveyor items, etc., can solve the problems of error-prone, high cost, small ceramic identification features, etc., and achieve high reliability of flipping , the effect of high turning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific embodiments:

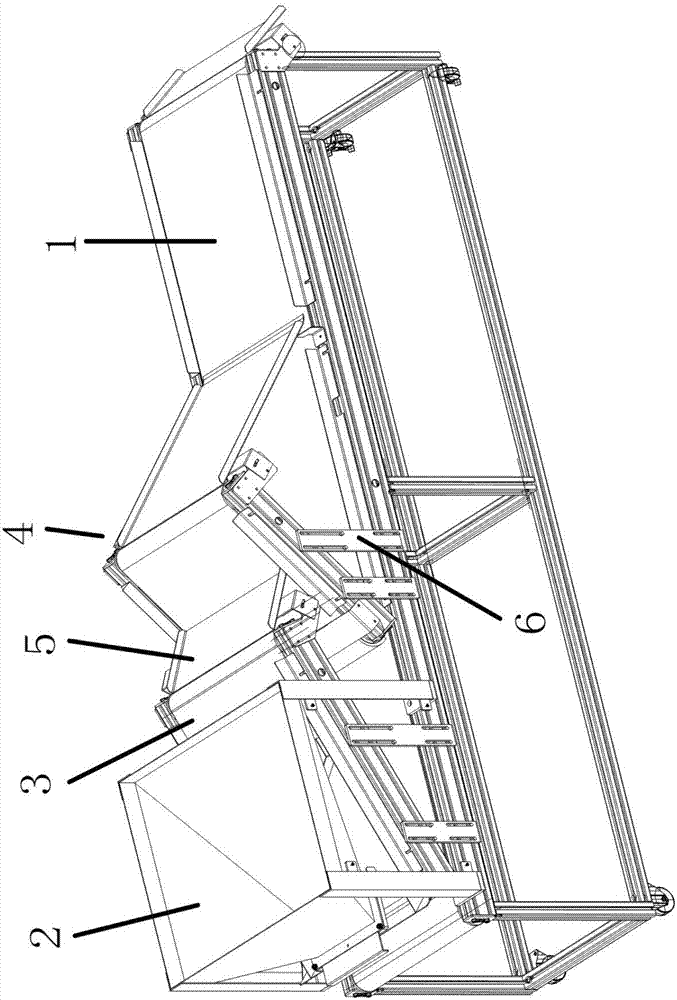

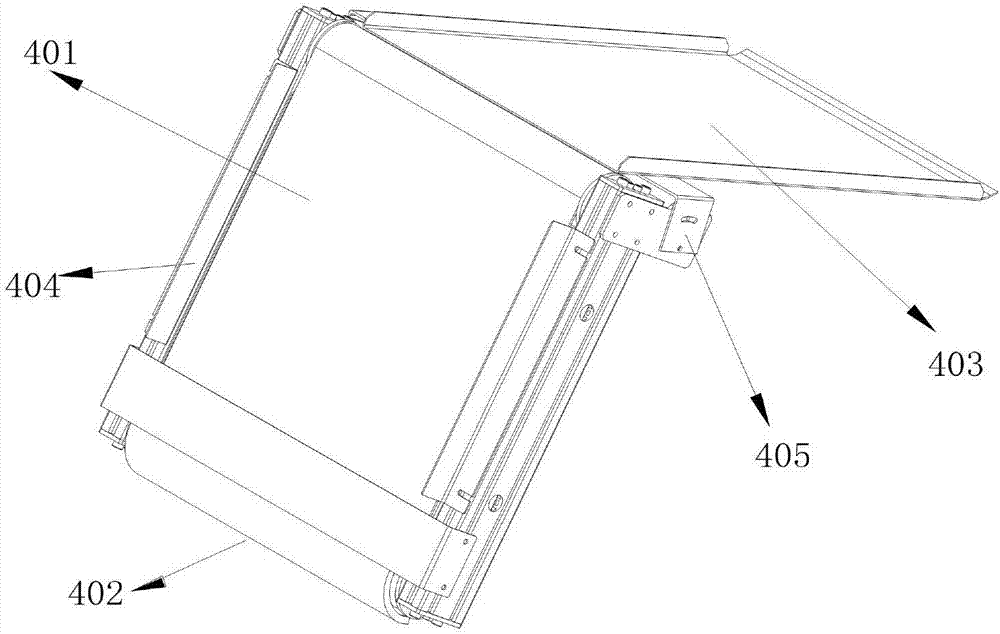

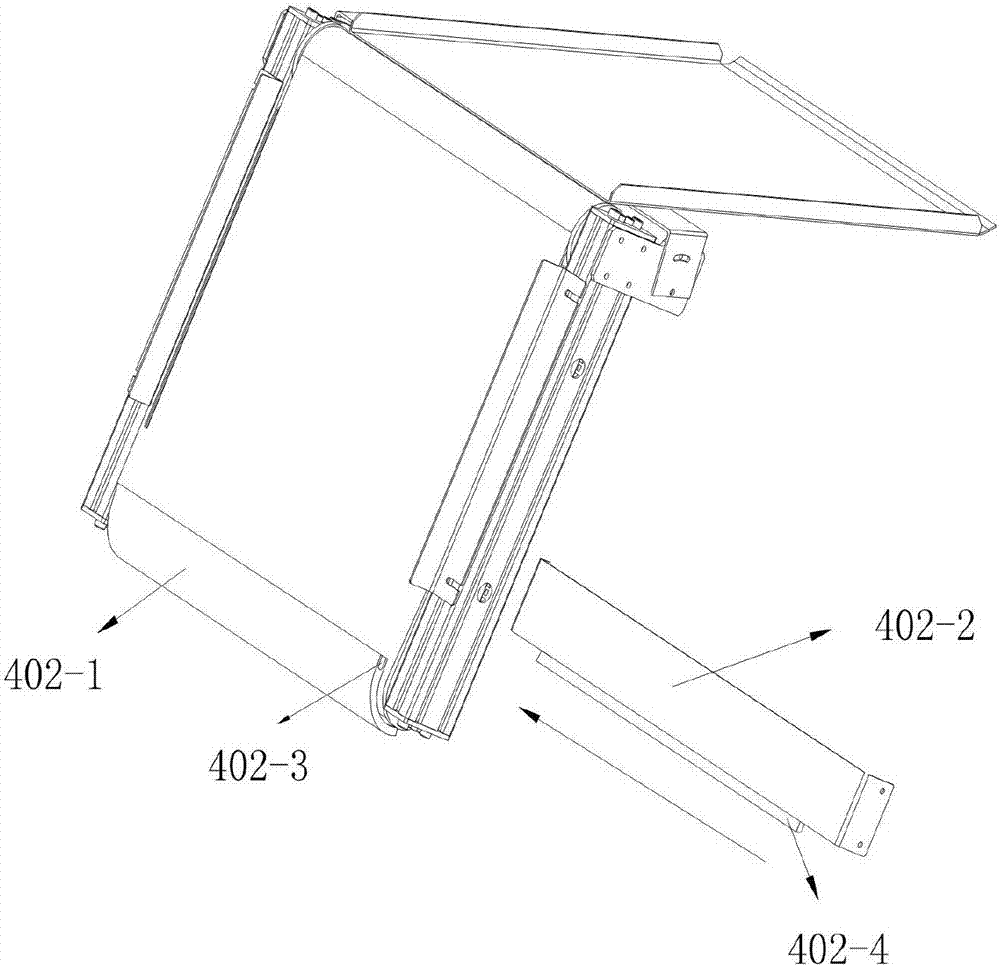

[0017] See attached Figure 1 to 3 As shown, the reversing line for items with large differences in surface friction coefficients in this embodiment includes a discharge conveyor line 1, a storage hopper 2, a shunt conveyor line 3, and a reversing device 4. The items have two different surface friction coefficients. Larger ceramics. Among them, the storage hopper 2 and the turning device 4 are successively erected in the downstream direction above the discharge conveying line 1. The branching conveying line 3 is located between the storage hopper 2 and the turning device 4, and the branch is conveyed There is a transition slide 5 for transition between the line 3 and the transmission conveying mechanism 401, which transports the ceramics from the storage hopper 2 to the turning device 4; the turning device 4 is transmitted by a transmission and conveying mechanism 401 using a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com