A kind of separation method of triethylamine and water

A separation method, triethylamine technology, applied in amino compound purification/separation, organic chemistry, etc., can solve problems such as high residual amount of triethylamine, secondary pollution of lye, affecting purity, etc., to reduce content and improve purification Purity, the effect of improving the amount of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

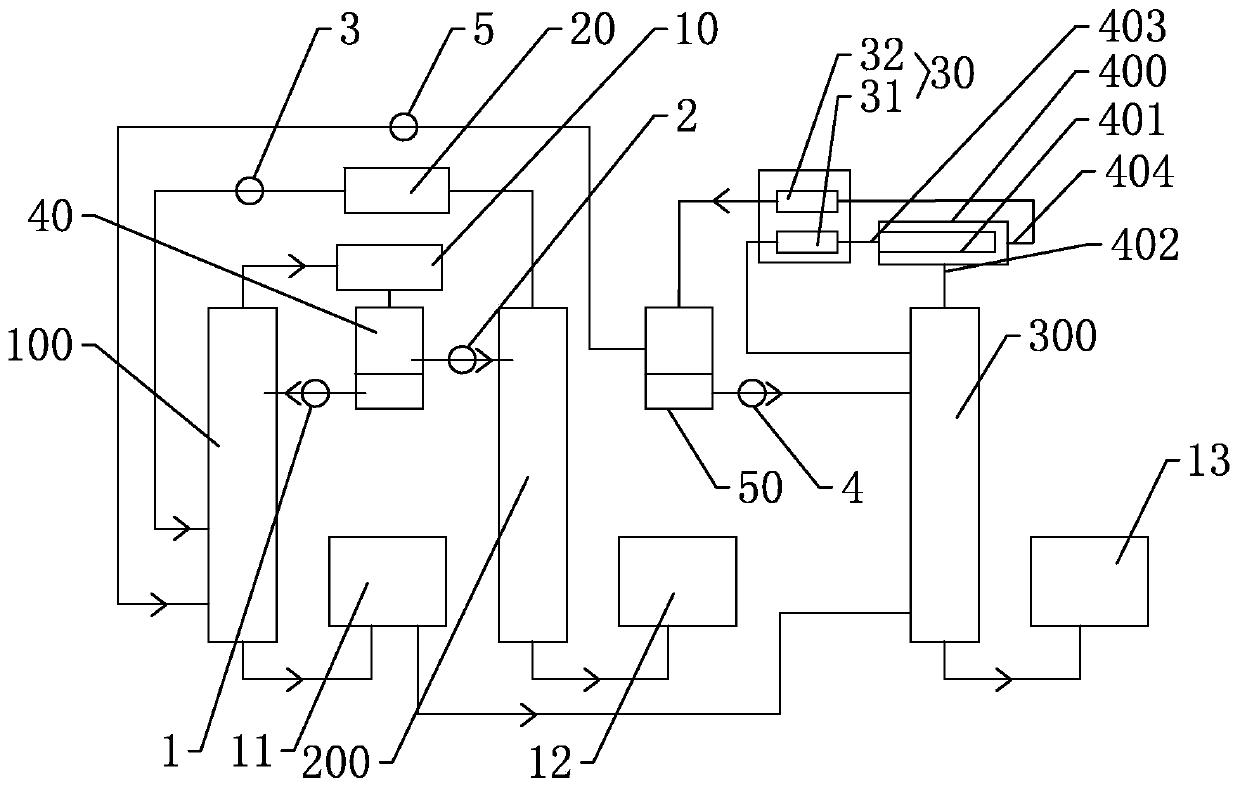

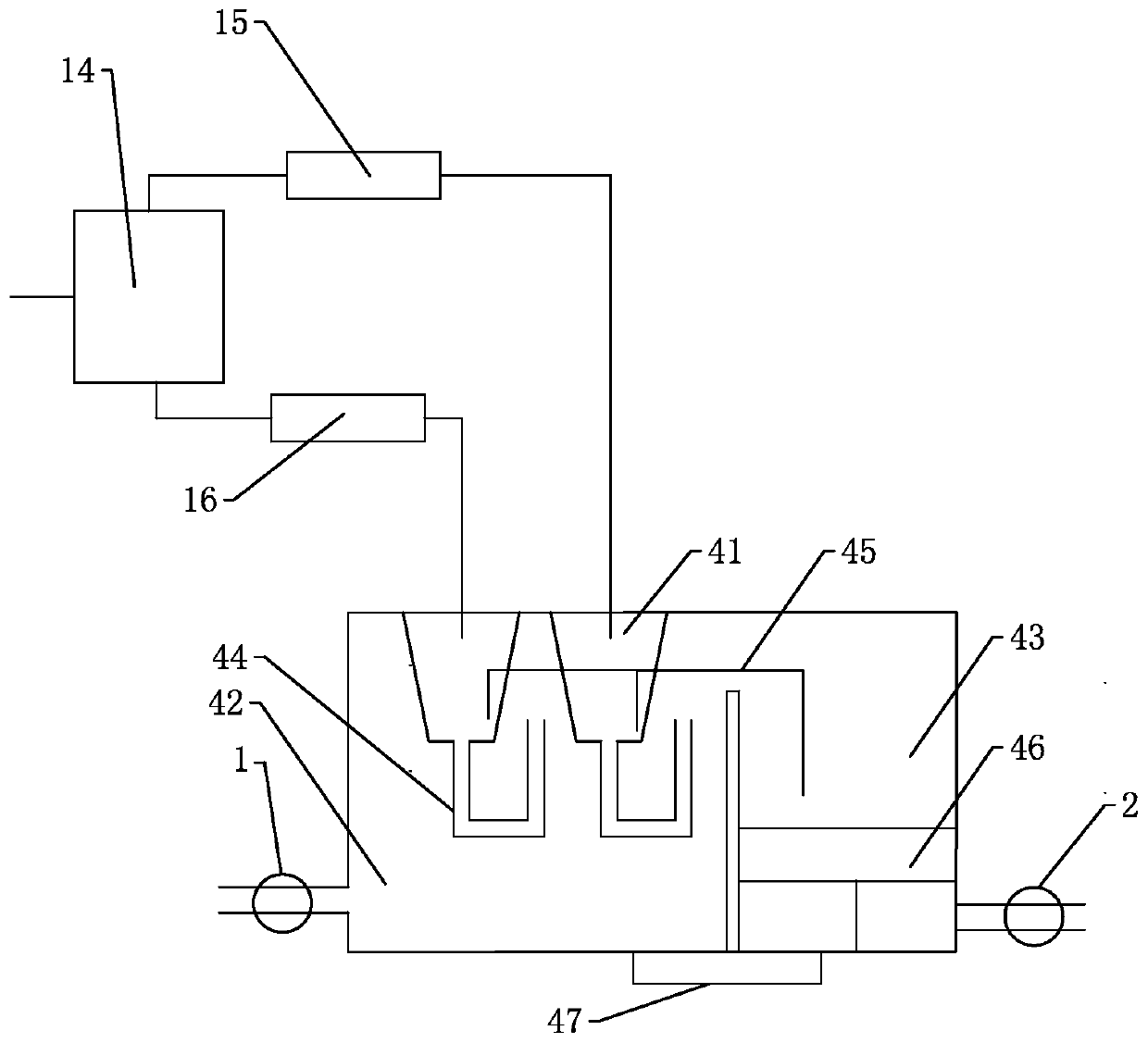

[0020] refer to Figure 1 to Figure 2 A kind of separation method embodiment of triethylamine and water of the present invention is described further.

[0021] A method for separating triethylamine and water, comprising the following steps:

[0022] 1. When the temperature is above 18.7°C, triethylamine is slightly soluble in water, and it is found in production practice that water will also remain in the triethylamine solution, so the triethylamine aqueous solution will be heated to 30°C in a heater. Layered, separated into a triethylamine solution with a water content of ≤5% and an aqueous solution with a triethylamine content of ≤5%, the mixed solution of triethylamine and water is separated first, and introduced into different distillation towers for simultaneous separation , improve the separation rate, and the purity after separation.

[0023] Two, the pressure value of the first rectifying tower 100 is set as normal pressure, the pressure value setting of the second r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com