Device and method for measuring clearance and rigidity of ball screw

A ball screw and measuring device technology, applied in the field of measurement, can solve problems such as troublesome operation and low precision, and achieve the effects of convenient processing and assembly, high measurement precision, and adjustable damping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

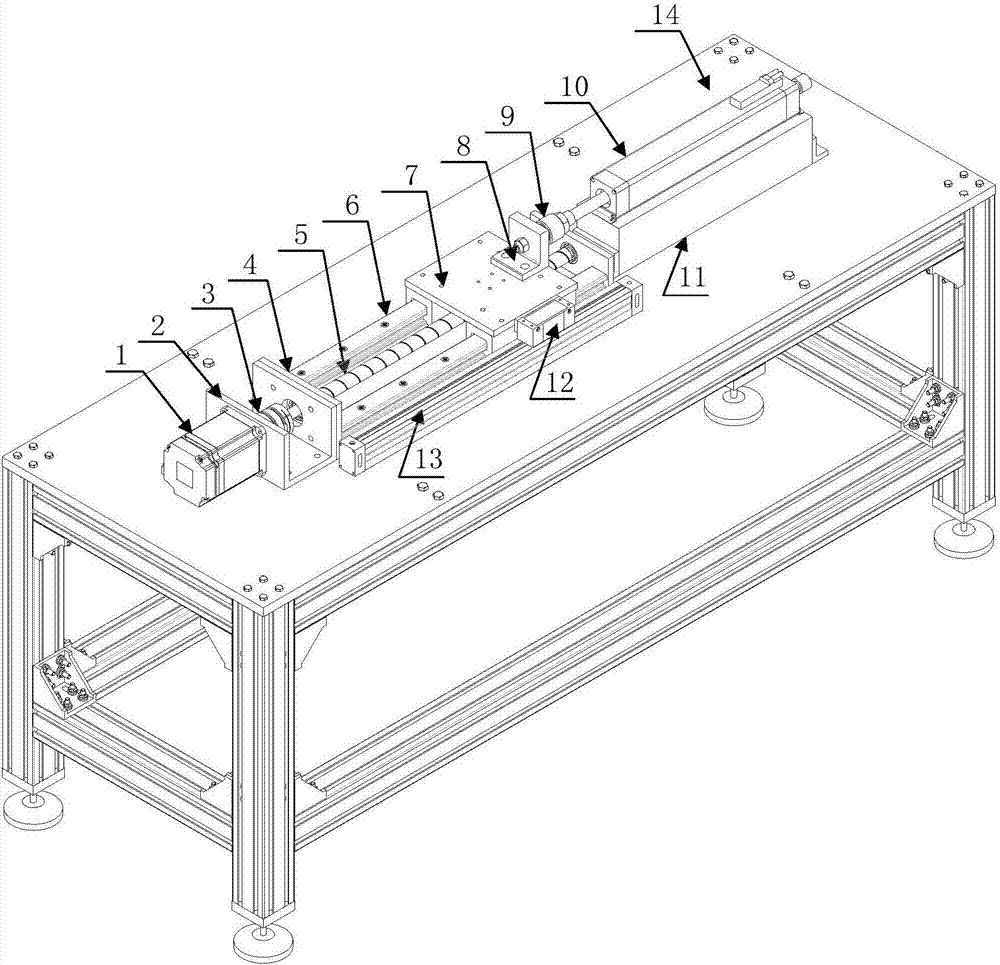

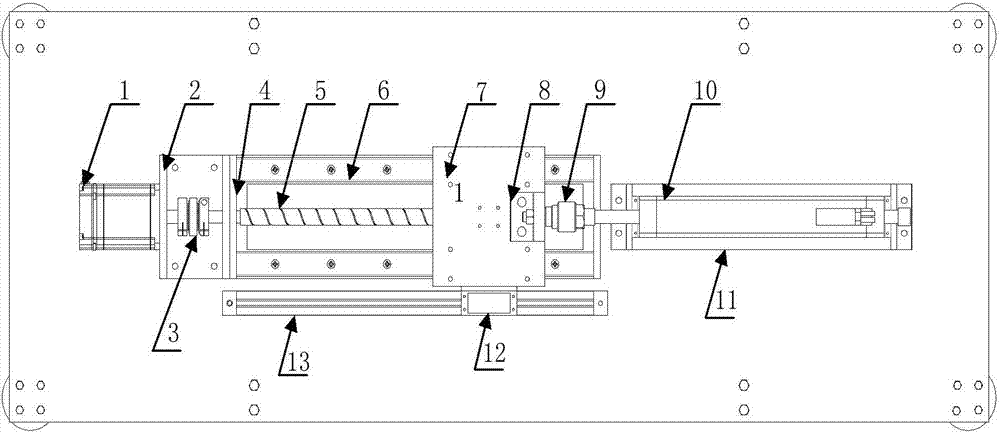

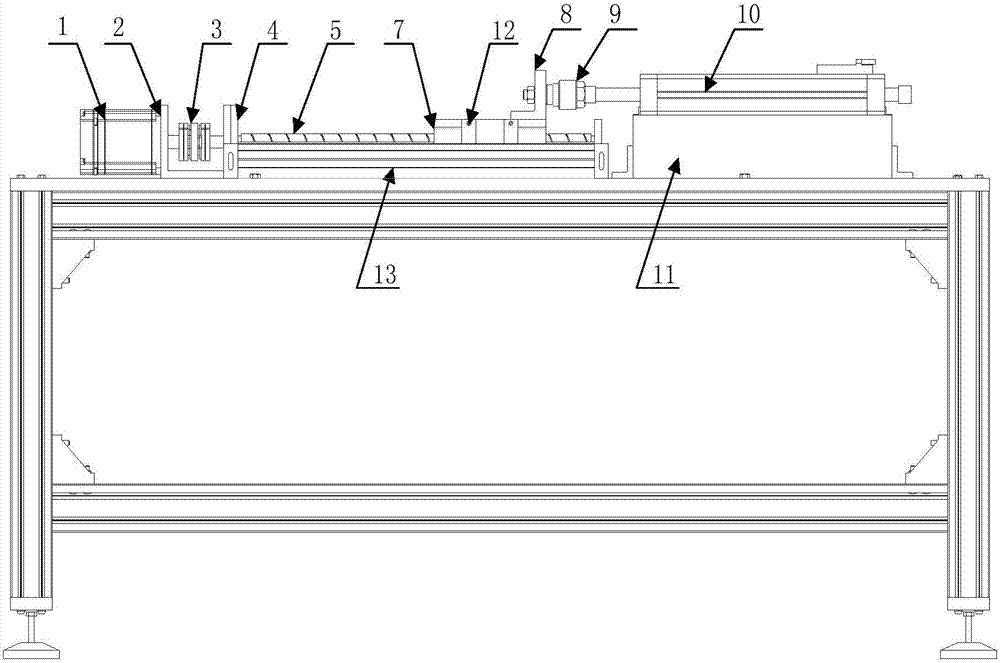

[0035] Such as Figure 1-Figure 5 As shown, a ball screw clearance and stiffness measuring device, including a ball screw transmission unit, a displacement detection unit and a damping loading unit;

[0036] The ball screw transmission unit includes a servo motor 1, a shaft coupling 3, a ball screw 5, a slider 7 and two linear guide rails 6, the servo motor is mechanically connected to one end of the motor base 2, and the other end of the motor base is mechanically connected. One end is mechanically connected to one end of the lead screw base 4, and the bottom plate of the motor base is fixed on the test bench 14 by bolts. The motor base has a U-shaped structure, and the coupling 3 is located in the hollow of the motor base. The input of the coupling The output end of the coupling is directly connected to the output end of the servo motor, and the output end of the coupling is connected to one end of the ball screw lever. The ball screw is placed on the screw base, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com