Minority carrier lifetime tester probe and minority carrier lifetime tester

A technology of minority carrier lifetime and tester, which is applied in the direction of single semiconductor device testing, semiconductor characterization, etc., can solve the problems of measuring semiconductor material surface unevenness, large measurement error, inconvenient use, etc., and achieve compact and reasonable structure layout and accurate voltage value , the effect of overall structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

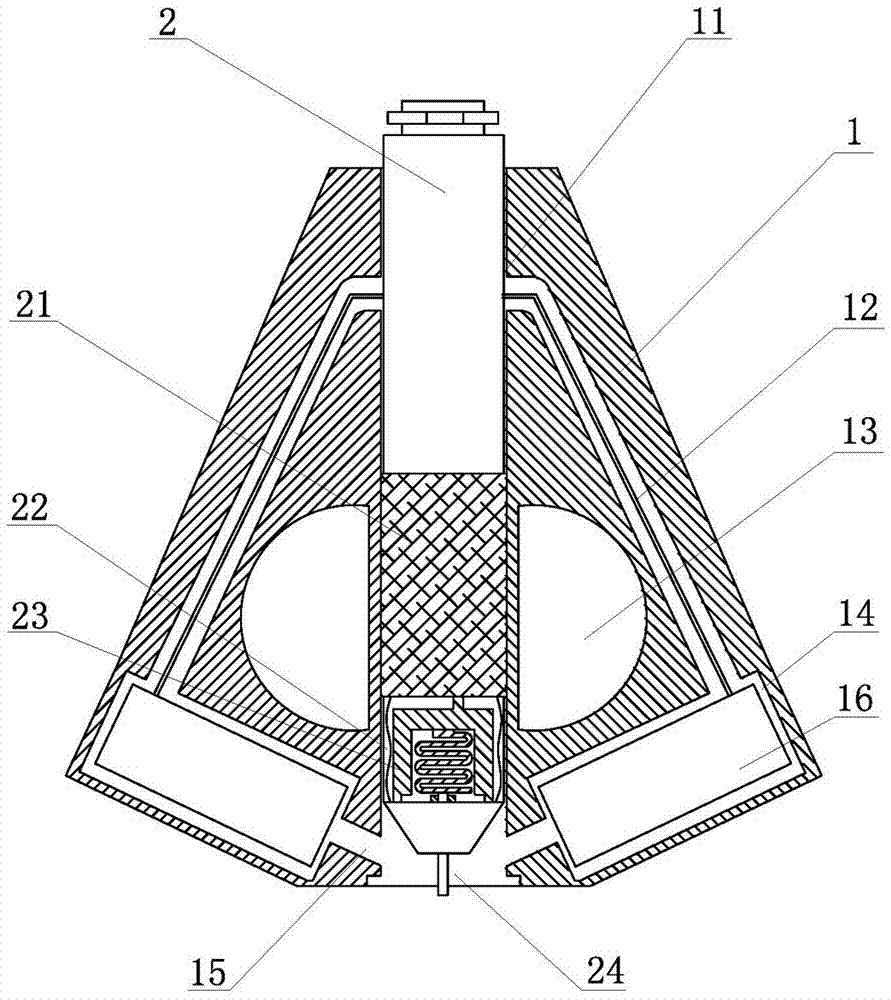

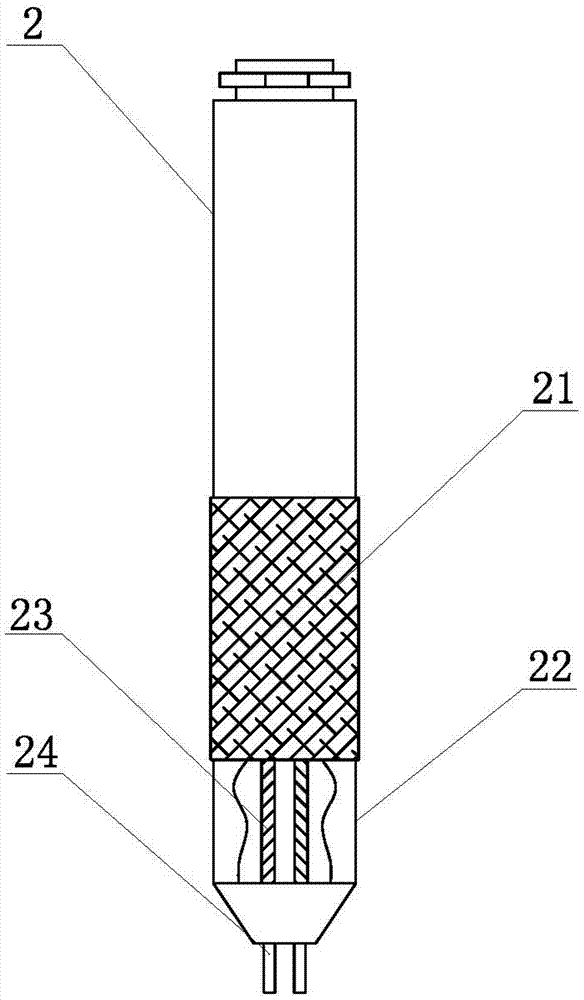

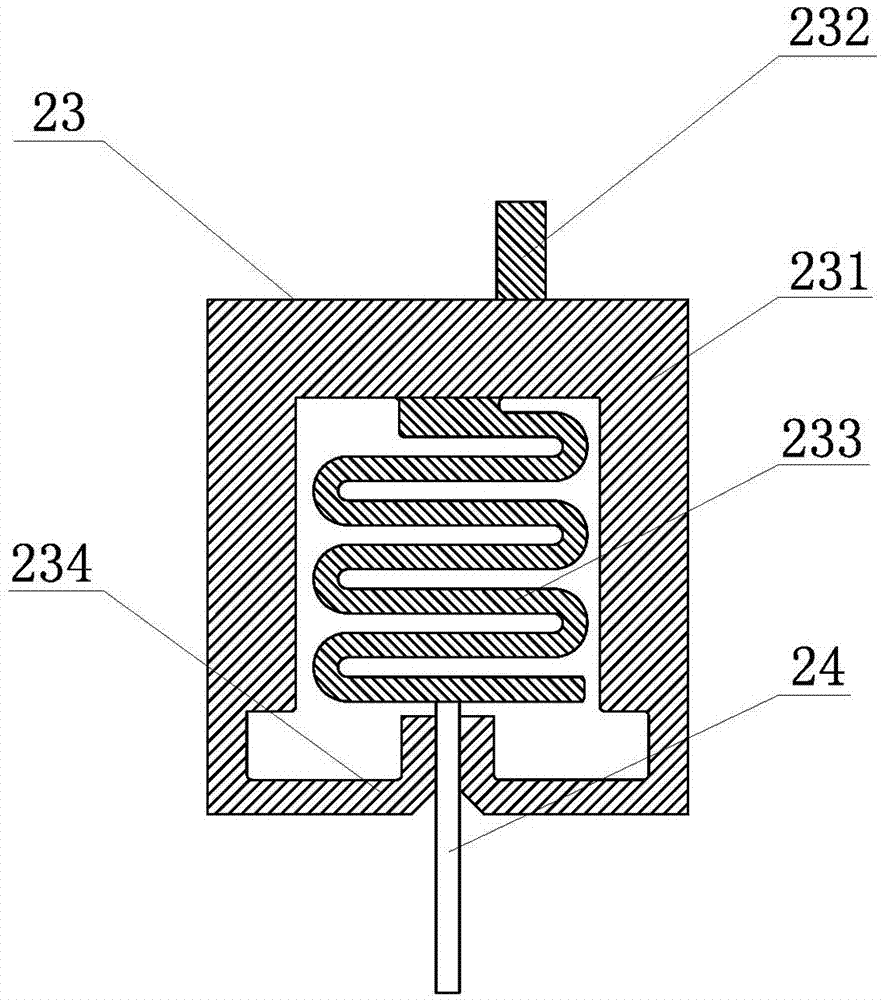

[0040] Embodiment: The process of using the present invention to measure semiconductor materials is to firstly carry out surface cleaning treatment on the semiconductor material to be measured to remove the pollutants and oil stains on the surface; Two probes 24 are in contact with the semiconductor material to be tested, and the AD acquisition module 6 in the host computer 3 monitors in real time whether the voltage value between the two probes 24 is stable through the analog input port 61, and transmits the signal to the control module 4, when the measured When the voltage value is unstable, the control module 4 prompts to re-contact until the voltage detection value is stable, and the control module 4 drives the constant current source circuit 51 in the power supply module 5 to select a suitable constant current source gear according to the resistivity of the sample. Real-time and intuitive monitoring of the unevenness of the material surface improves the accuracy of the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com