Cutting and walking servo-actuated regulating system of combined harvester

A technology of combine harvester and adjustment system, which is applied in the field of combined harvester cutting and walking follow-up adjustment system, can solve the problems of heavy cutting and missing cutting, excessive head strike, crop accumulation, etc., and achieves small and good crop strike. The effect of cutting performance, increased versatility and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

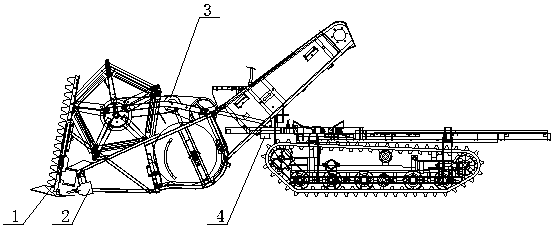

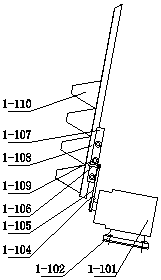

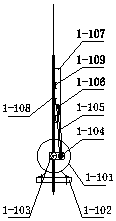

[0025] like figure 1 As shown in the figure, a combined harvester cutting and walking follow-up adjustment system includes a double vertical cutter transmission device 1, a main cutter transmission device 2, a reel and screw conveyor auger transmission device 3, a speed measurement and follow-up adjustment system 4. The double vertical cutter transmission device 1 is divided into a left vertical cutter transmission device 1-1 and a right vertical cutter transmission device 1-2, which are respectively arranged on the left and right sides of the advancing direction of the header, and the main cutter transmission Device 2 is located on the left side of the advancing direction of the header and behind the left vertical cutter transmission device 1-1. The reel and screw conveyor auger transmission device 3 are located on the right side of the advanci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com