Road and bridge dotting equipment for construction

A bridge and equipment technology, which is applied in the field of construction road and bridge management equipment, can solve the problems of affecting management operations, dust pollutes the environment, and high labor intensity, and achieves the effects of preventing friction damage, reducing labor intensity, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

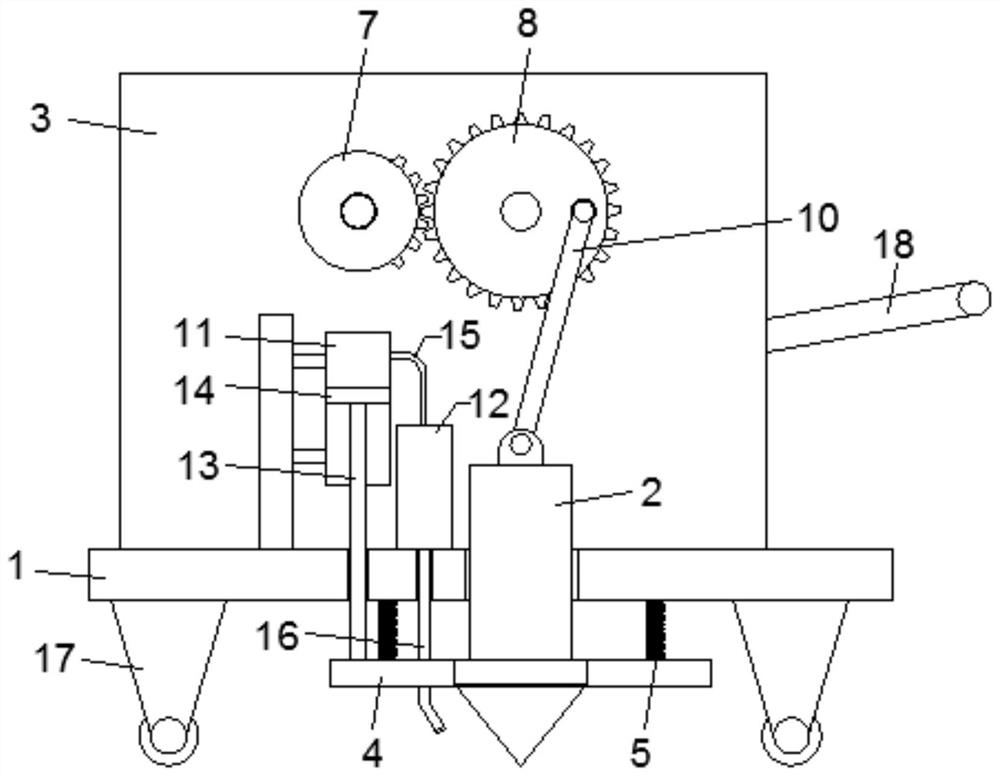

[0032] Such as figure 1 , Figure 4 and Figure 5 Shown, a kind of road bridge dotting equipment for construction, comprises mobile seat 1, dotting column 2, control mechanism and spraying mechanism, the upper side of mobile seat 1 is provided with installation frame 3, and the outer wall of installation frame 3 is provided with push rod 18. The bottom surface of the moving seat 1 is provided with four wheels 17 in a rectangular distribution, and the construction personnel can move the device conveniently through the hand push rod 18. Dotting column 2, control mechanism and spraying mechanism are all arranged on the inside of installation frame 3, and dotting column 2 is movably interspersed on the mobile seat 1, and the bottom end of dotting column 2 is made as conical, after dotting column 2 hits on the road surface, The tip provided can realize the dotting operation on the road surface, the dotting post 2 is fixedly fitted with an auxiliary plate 4, the diameter of the au...

Embodiment 2

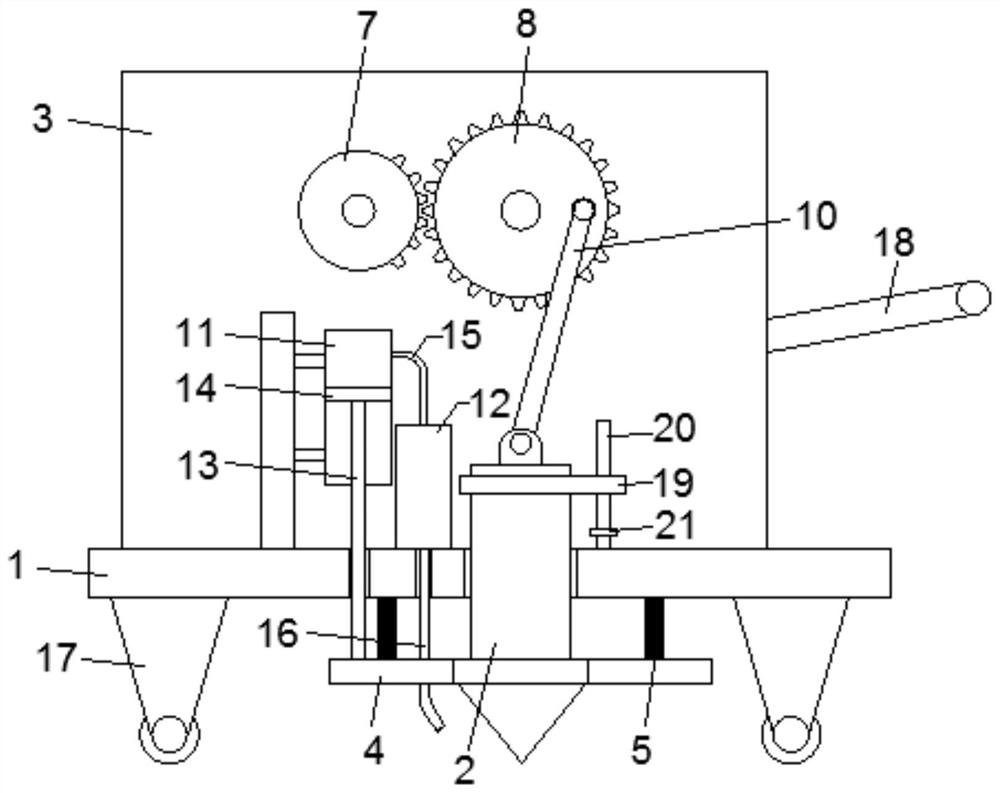

[0036] On the basis of embodiment 1, dotting post 2 is also provided with regulating mechanism, as figure 2 , Figure 4 and Figure 5 As shown, the adjustment mechanism includes a limit plate 19 and a threaded rod 20, the limit plate 19 is fixedly fitted on the upper end of the dotting column 2, the limit plate 19 is located above the moving seat 1, and the limit plate 19 is provided with a through hole; Threaded rod 20 is fixedly connected on the mobile seat 1, and is positioned at the right side of dotting post 2, and the top of threaded rod 20 runs through the through hole, and threaded rod 20 is connected with adjusting nut 21, and adjusting nut 21 is positioned at the below of limiting plate 19. Can control the striking degree of dotting post 2 to road surface by regulating mechanism. When the adjusting nut 21 is turned upwards, the closer the adjusting nut 21 is to the limit plate 19, the smaller the space for the dotting column 2 to descend, and the degree of impact ...

Embodiment 3

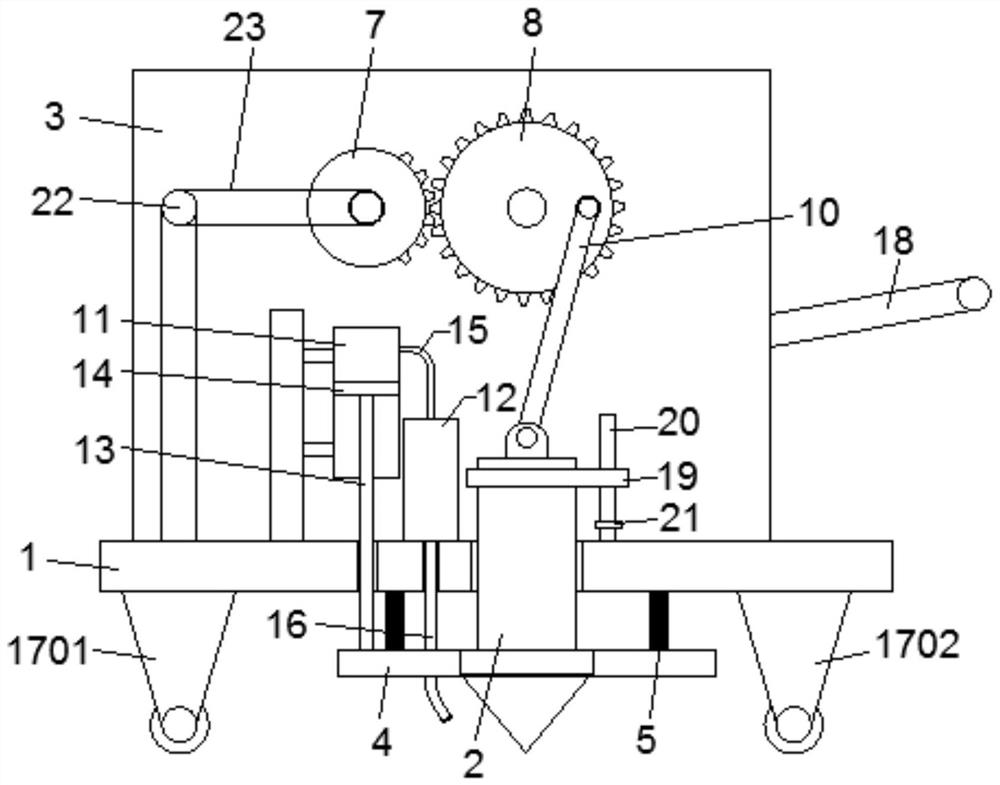

[0038] Above-mentioned embodiment needs construction personnel to push mobile seat 1, realizes multiple dotting operations, such as image 3 , Figure 4 and Figure 6 As shown, in this embodiment, the wheels 17 are divided into driving wheels 1701 and driven wheels 1702, wherein the driving wheels 1701 and the driven wheels 1702 are respectively provided with two, and the two driving wheels 1701 are located on the same side. The second rotating shaft is connected between the wheels 1701. When the second rotating shaft is rotated under force, the two driving wheels 1701 can rotate synchronously; The three rotating shafts 22 and between the third rotating shaft 22 and the second rotating shaft are connected through a transmission assembly, wherein the transmission assembly includes a belt 23 and a pulley 24 . When the motor 6 starts to work, the motor shaft rotates, and under the action of the third rotating shaft 22 and the transmission assembly, the second rotating shaft wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com