Preparation method of supported catalyst for regenerating amine solution rich in carbon dioxide

A supported catalyst and carbon dioxide-enriched technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, and separation methods, can solve the problems of high energy consumption and high cost of carbon capture, and achieve easy separation, simple process, and high impact small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

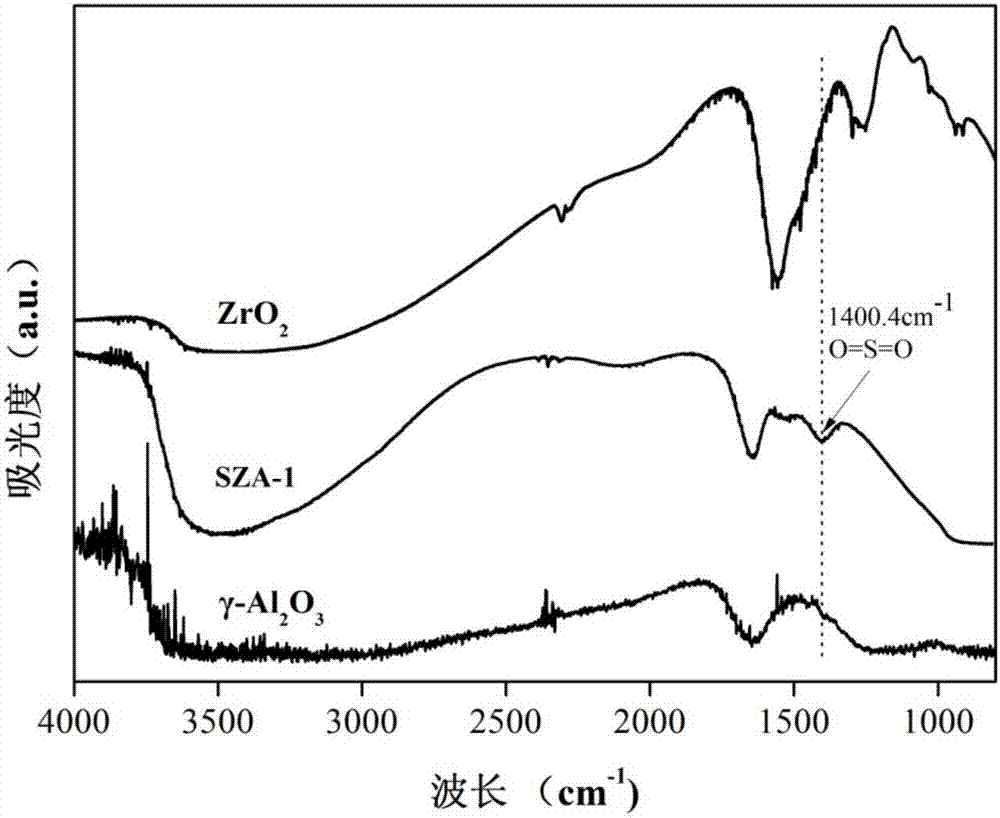

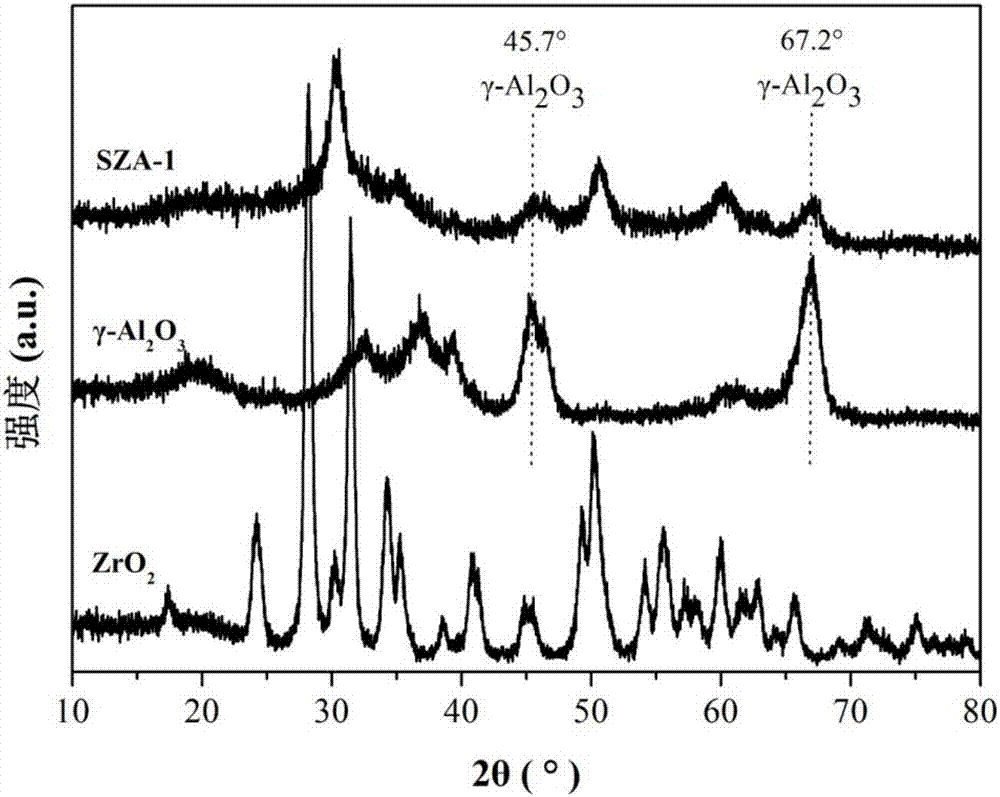

[0034] (1) Supported catalyst SO 4 2- / ZrO 2 -γ-Al 2 o 3 preparation of

[0035] In the first step, 24g zirconium oxychloride ZrOCl 2 ·8H 2O was dissolved in deionized water to obtain a 0.5mol / L aqueous solution, and then 9.2g of γ-Al was added 2 o 3 Thoroughly mix to obtain mixed solution A; vigorously stir and disperse mixed solution A, and add ammonia water to mixed solution A drop by drop to make it hydrolyze and precipitate under alkaline conditions, and leave to stand at room temperature for 12 hours to obtain mixed solution B; The mixture B was filtered, washed, and then dried at 110°C for 6 hours to obtain substance C;

[0036] In the second step, substance C is ground into powder, and in 0.5mol / L H 2 SO 4 (The volume mass ratio of the liquid in milliliters to the solid in grams is 15:1) Stir and impregnate in the solution for 1 hour, then dry at 110°C for 6 hours, and finally place the sample in a horse-boiling furnace and calcinate at 650°C for 3 hours to o...

Embodiment 2

[0049] With embodiment 1, its difference is that in catalyst preparation process, ZrO 2 and γ-Al 2 o 3 The mass ratio of is 2:1, and the obtained catalyst is marked as SZA-2. Similarly, the desorption experiment of carbon dioxide-rich amine solvent was carried out, and the results showed that compared with the blank MEA, SZA-2 can reduce the desorption energy consumption by 24.8%.

Embodiment 3

[0051] With embodiment 1, its difference is that in catalyst preparation process, ZrO 2 and γ-Al 2 o 3 The mass ratio of is 1:2, and the obtained catalyst is marked as SZA-3. Similarly, the desorption experiment of carbon dioxide-rich amine solvent was carried out, and the results showed that compared with the blank MEA, SZA-3 could reduce the desorption energy consumption by 27.8%.

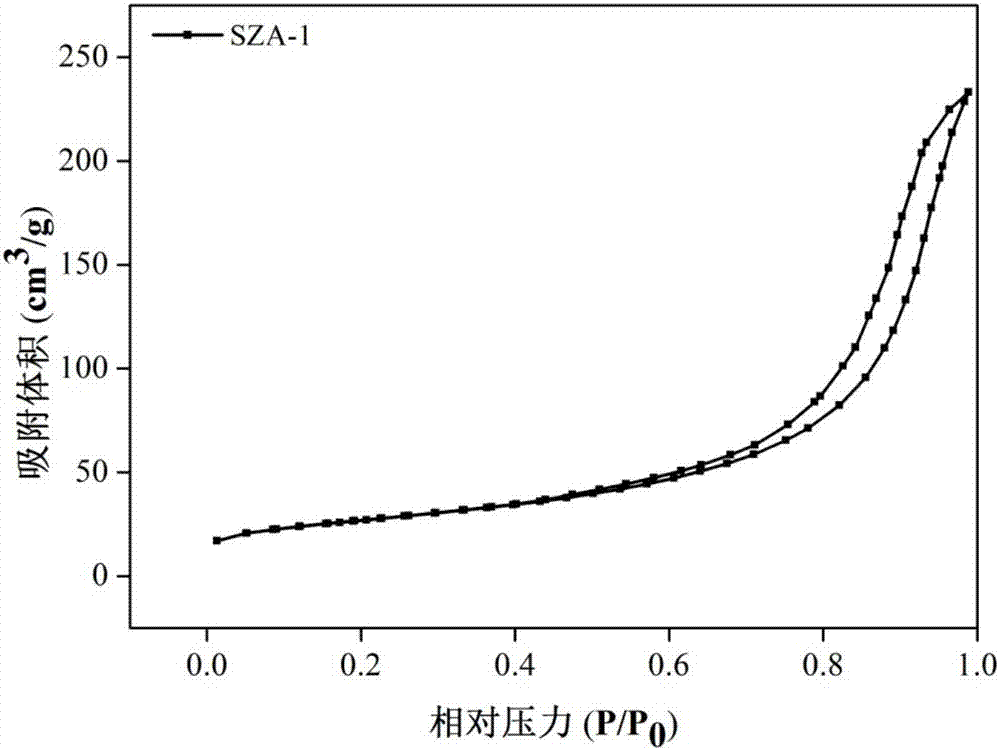

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com