Paper shredder based on automatic detection

An automatic detection and paper shredder technology, which is applied in the direction of measuring devices, weighing equipment with special properties/forms, instruments, etc., can solve problems such as the inability to detect the weight of the containing cavity, save cleaning time and improve cleaning speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

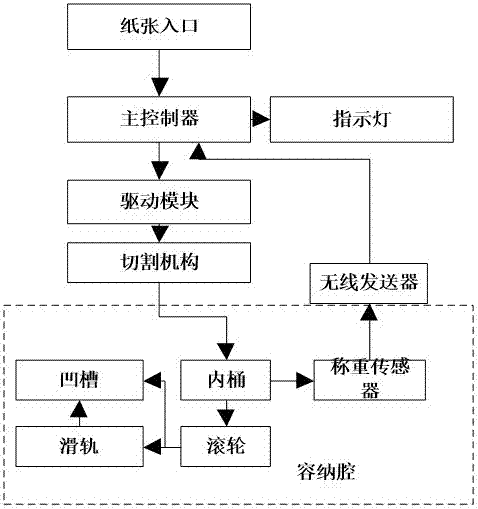

[0019] like figure 1 As shown, the present invention designs a paper shredder based on automatic detection, which includes a paper inlet, a main controller, a drive module, a cutting mechanism, and an accommodating chamber, wherein the main controller is connected with the driving module and the cutting mechanism in sequence, and the accommodating The cavity of the cavity is provided with an inner barrel with rollers on the top, and the inner wall of the cavity is provided with grooves for fixing the rollers and slide rails for providing sliding of the rollers; it also includes a load cell, a wireless transmitter, and an indicator light, among which The weighing sensor is arranged inside the inner bucket; the weighing sensor is used to detect the weight of shredded paper in the inner bucket to obtain a detection signal; the wireless transmitter is used to send t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com