Particle diameter monitoring system and fuzzy control method for traditional Chinese medicine powder grinding and processing production line

A technology of grinding and fuzzy control, applied in grain processing and other directions, can solve the problems of difficulty in forming a network, different requirements for crushing, complex parameters, etc., and achieve the effect of free assembly and disassembly and good immediacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

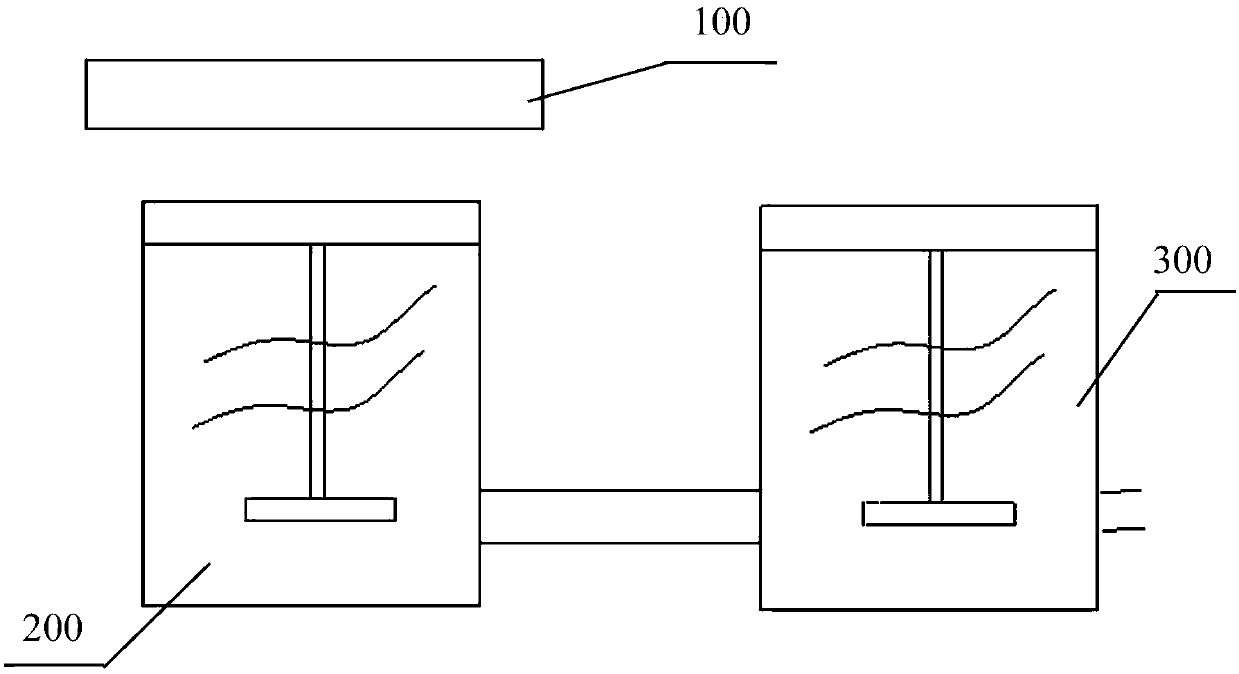

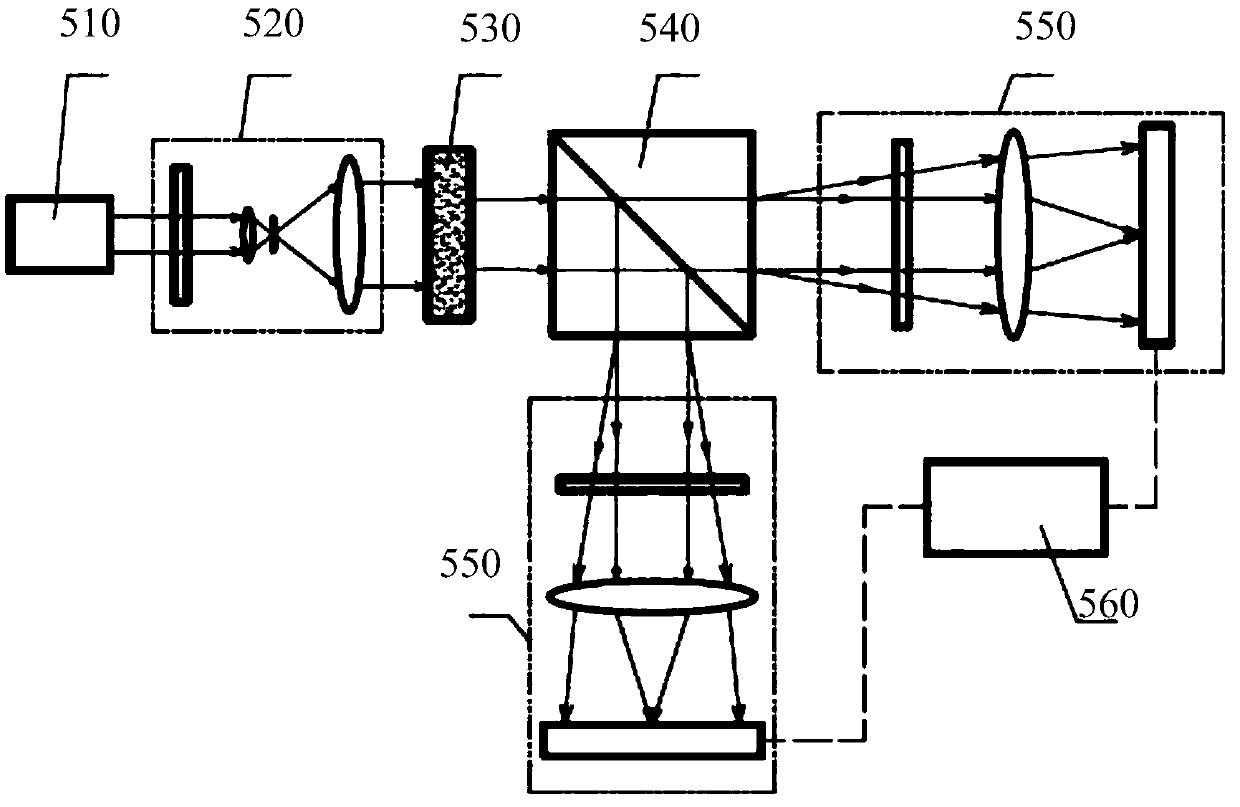

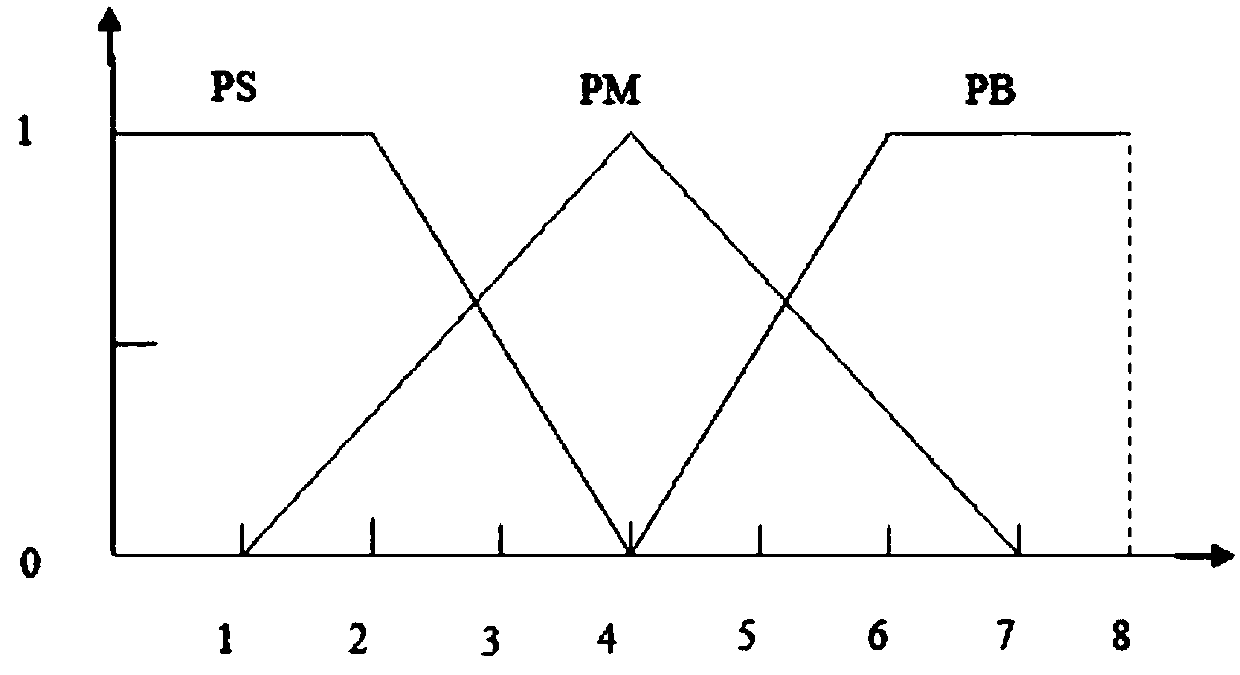

[0041] like figure 1 As shown, the present invention provides a particle size monitoring system for a traditional Chinese medicine powder grinding and processing production line, including: a plurality of sensing devices, the sensing devices include: a weighing sensor, which is arranged at the position of the feed port of the traditional Chinese medicine powder grinding and processing production line; a speed sensor, which It is arranged on the grinding machine to detect the rotational speed of the grinding machine; the screening device, which is a sieve with different apertures, is arranged at the feed port of the coarse grinding process device of the traditional Chinese medicine powder grinding and processing production line; the particle size detection device is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com