A method of machining a workpiece and a linear hammer

A technology for processing workpieces and linearity, applied in the field of linear hammers, can solve the problems of small application range and high cost of forging hammers, and achieve the effects of reduced waste, repeatable quality, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

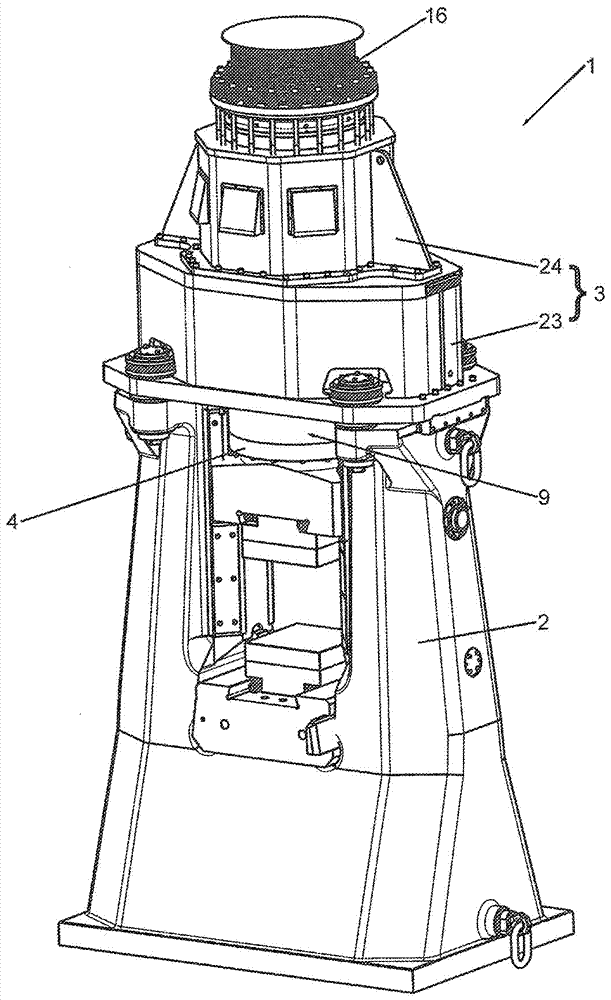

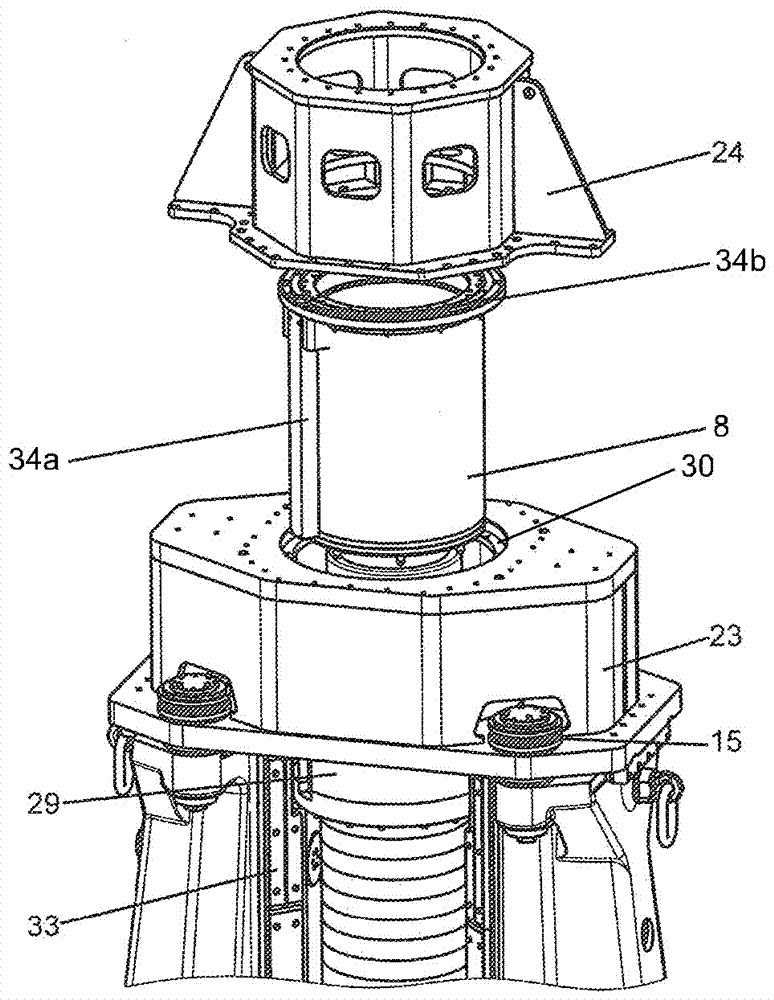

[0086] figure 1 A perspective illustration of the linear hammer 1 is shown. It comprises an anvil 2 which has a U-like profile. A head section 3 is arranged on the anvil 2 . In the exemplary embodiment shown, the head section 3 is composed of a lower head section 23 and an upper head section 24 .

[0087] In a manner not shown further, the header section 3 can also be designed in one piece.

[0088] A cover 16 is arranged on the head section 3 or on the upper head section 24 . A striker 4 is formed in the anvil 2 . The linear hammer 1 comprises an upper part 7 of a forging die 6 and a lower part 5 of the forging die 6 for machining a workpiece (not shown).

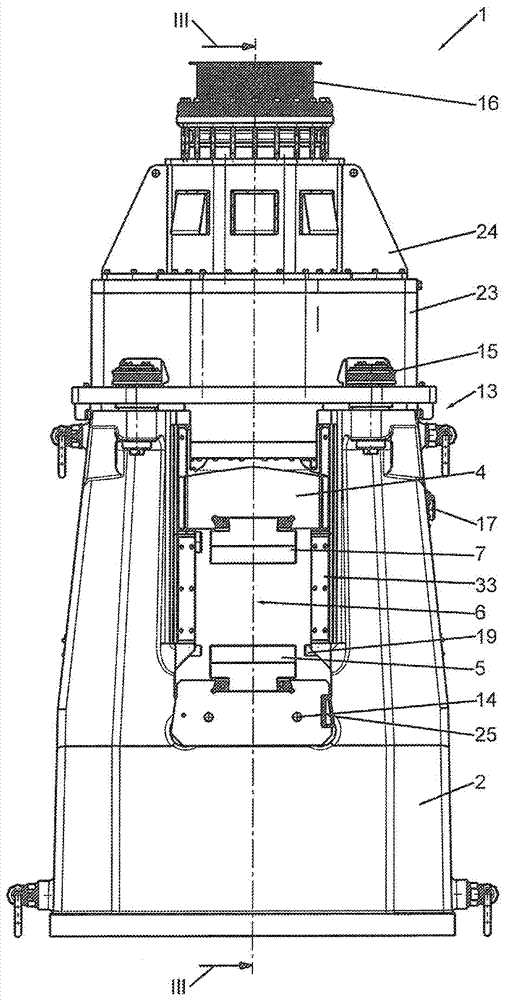

[0089] exist figure 2 is shown in schematic side view already in figure 1 The linear hammer shown in 1. The linear hammer 1 is here designed as a short-stroke die hammer. The linear hammer 1 comprises the mentioned anvil 2 , an anvil insert 14 , a head section 3 and a hammer head 4 .

[0090] The head section 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com