Polishing device and automatic metallurgical polishing machine

A technology of polishing device and polishing machine, which is applied in the direction of surface polishing machine tools, grinding drive devices, grinding/polishing equipment, etc., can solve problems such as difficulties and uncertainty of artificial polishing accuracy, and achieve low device cost and convenient installation. The effect of tearing down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

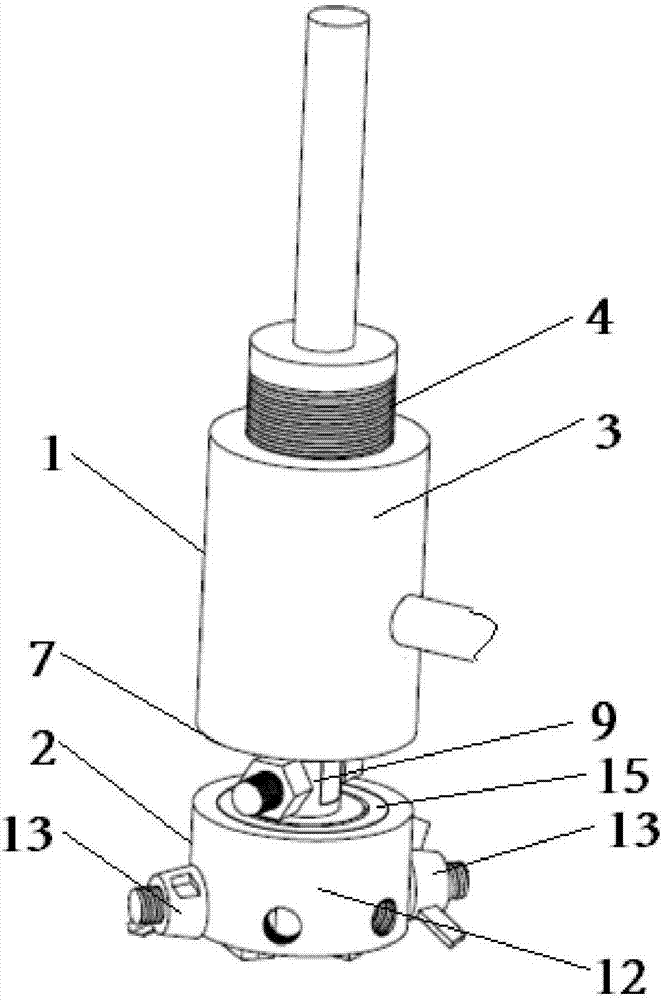

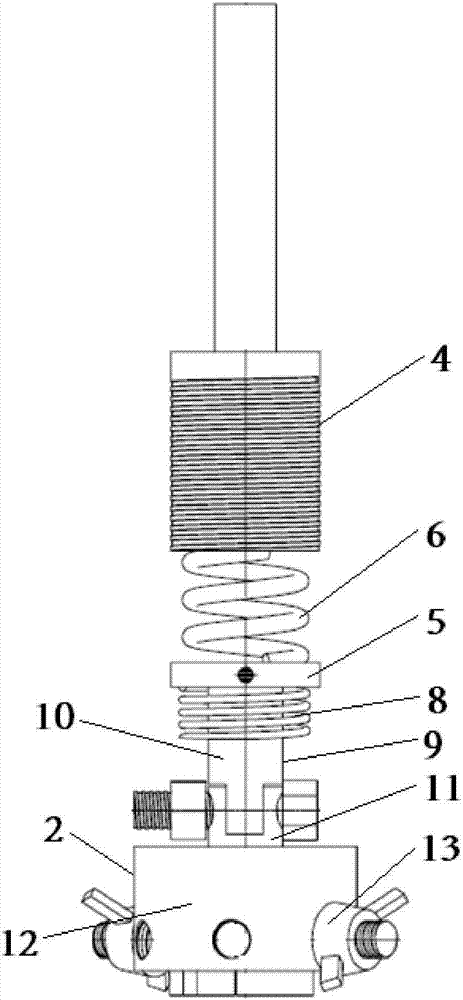

[0028] see figure 1 with figure 2 As shown, a polishing device includes a feed mechanism 1 and a clamping mechanism 2, and the feed mechanism is connected to the clamp mechanism; the feed mechanism includes a housing 3 and an extrusion head 4, and the extrusion The indenter is connected to the housing through threads, and the housing is floatingly connected to the polishing turntable through a support frame. The support frame is slidingly connected to a guide groove arranged on the central axis of the polishing turntable. There is a buffer spring; the housing is provided with a sliding partition 5, and the sliding partition is slidably connected with the box body; an extrusion spring 6 is arranged between the extrusion head and the sliding partition, and the The sliding partition is connected with the clamping mechanism. A sealing plate 7 is provided at the end of the housing opposite to the extrusion head, the sealing plate is fixed to the housing, and a support spring 8 i...

Embodiment 2

[0030] Embodiment 2. This embodiment is improved on the basis of Embodiment 1. The content described in Embodiment 1 is also included in this embodiment, and will not be repeated here.

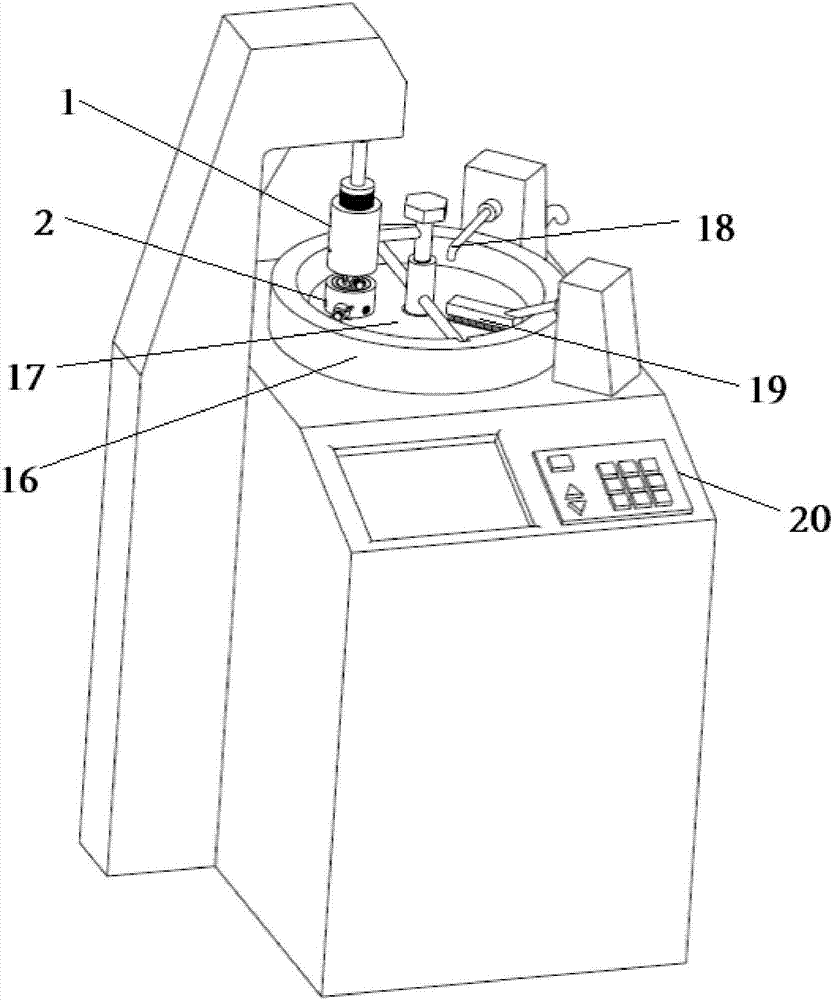

[0031] see image 3 with Figure 4 As shown, an automatic metallographic polishing machine is also provided in this embodiment, including the polishing device; the automatic metallographic polishing machine also includes a polishing turntable 16, and the polishing turntable corresponds to the position of the polishing device Setting, a polishing cloth 17 is arranged inside the polishing turntable. The automatic metallographic polishing machine also includes a water inlet mechanism 18 and a cleaning mechanism 19, and the water inlet mechanism and the cleaning mechanism are arranged corresponding to the positions of the polishing turntable. The automatic metallographic polishing machine also includes a controller 20, and the power mechanism is electrically connected to the controller. The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com