Radial tire with two steel rings and single cord fabric layer

A technology for radial tires and plies, applied to tire parts, reinforcement layers of pneumatic tires, transportation and packaging, etc., can solve the problems of increasing the density of outer rings and excessive density of inner rings, etc., to expand the bearing capacity The effect of large force range and load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

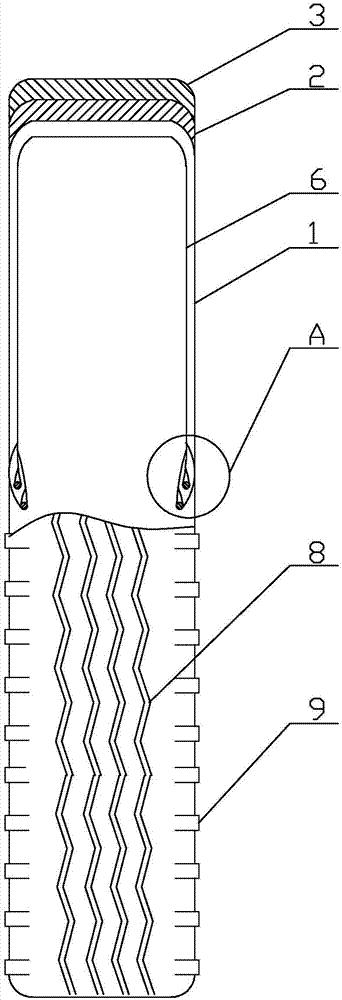

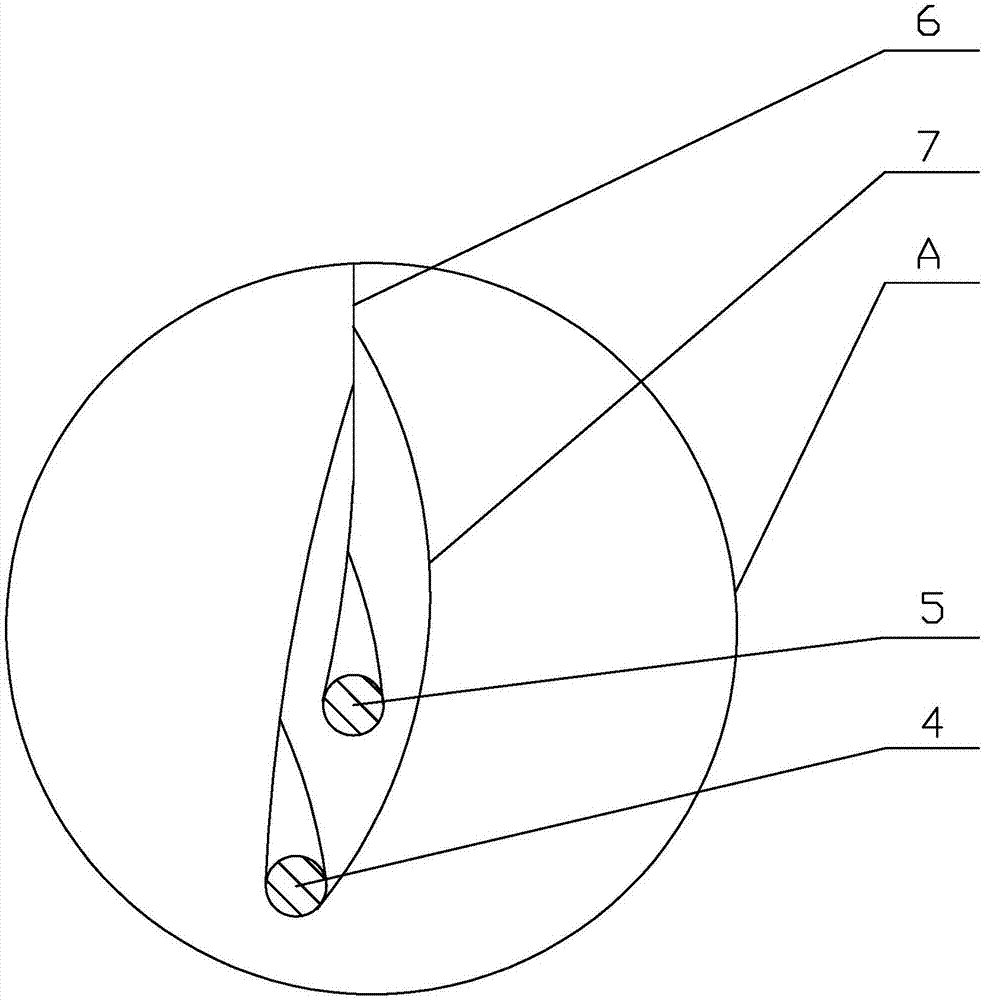

[0015] Embodiment one, such as figure 1 , 2 As shown in , the present invention provides a double-steel ring single-ply radial tire, which includes a ply 1, a belt 2 and a crown 3 from the inside to the outside, and the inner circles on the left and right sides of the ply 1 are respectively A double-layer traveler is provided, the double-layer traveler includes an inner traveler 4 and an outer traveler 5, the ply 1 is provided with steel cords 6, and the adjacent steel cords 6 are staggered and turned outwards in sequence Wrapped on the inner traveler 4 and the outer traveler 5 . The present invention changes the design of only one traveler in the prior art, adopts two layers of traveler inside and outside, and the adjacent steel cords 6 are sequentially staggered and turned over to wrap the inner traveler 4 and the outer traveler 5 On the other hand, the density of the steel cords 6 on the inner circumference of the carcass layer 1 is greatly increased without contacting ea...

Embodiment 2

[0017] Embodiment two, such as figure 1 , 2 As shown in , the present invention provides a double-steel ring single-ply radial tire, which includes a ply 1, a belt 2 and a crown 3 from the inside to the outside, and the inner circles on the left and right sides of the ply 1 are respectively A double-layer traveler is provided, the double-layer traveler includes an inner traveler 4 and an outer traveler 5, the ply 1 is provided with steel cords 6, and the adjacent steel cords 6 are staggered and turned outwards in sequence Wrapped on the inner traveler 4 and the outer traveler 5, the steel cords 6 are evenly distributed on the double-layer traveler. The steel cords 6 are evenly arranged, and the force on the tire is more uniform.

[0018] The length of the steel cord 6 wrapped on the outer bead ring 5 is shorter than the length of the steel cord 6 wrapped on the inner bead ring 4 . Since the diameter of the outer bead 5 is greater than the diameter of the inner bead 4, if al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com