A spinning device based on improved ring spinning and used for auxetic composite yarn with a uniform wrapping angle

A wrapping yarn and ring spinning technology, which is applied in the field of spinning, can solve problems such as strong limitations of spinning methods, unsuitability for continuous production, uneven yarn structure, etc., to achieve improved wrapping effect, simple spinning method, The effect of improving yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

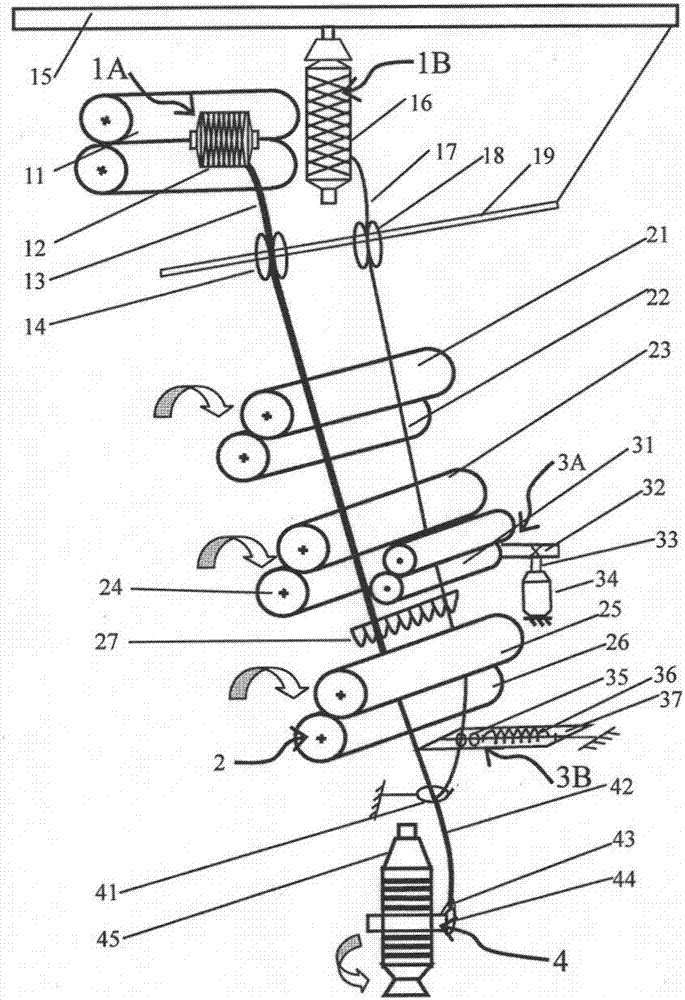

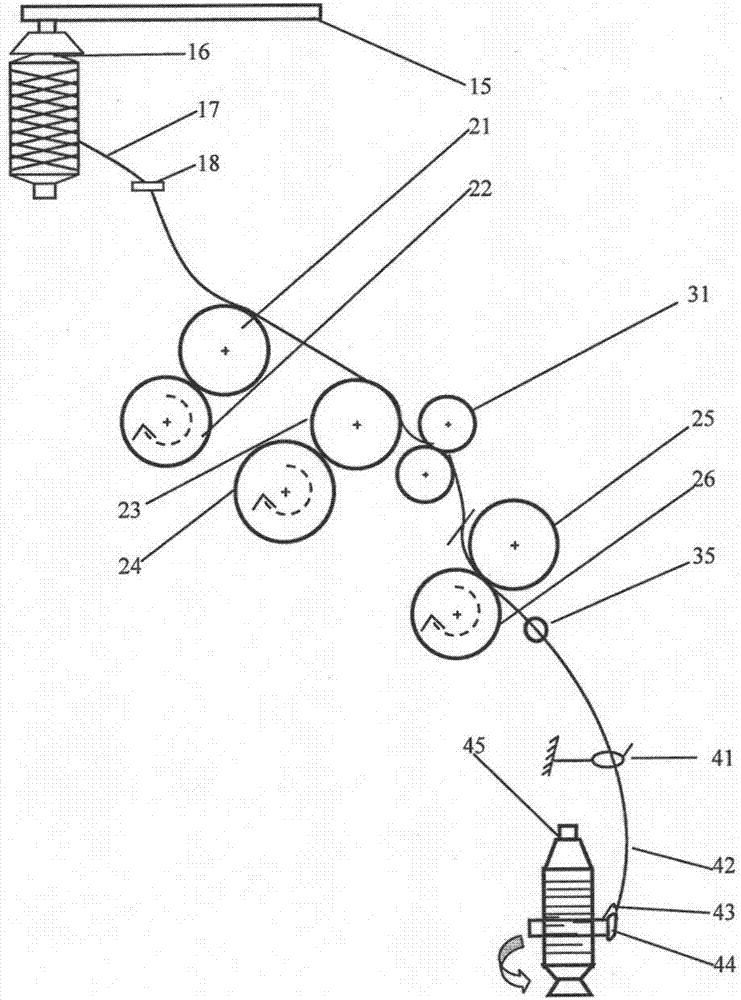

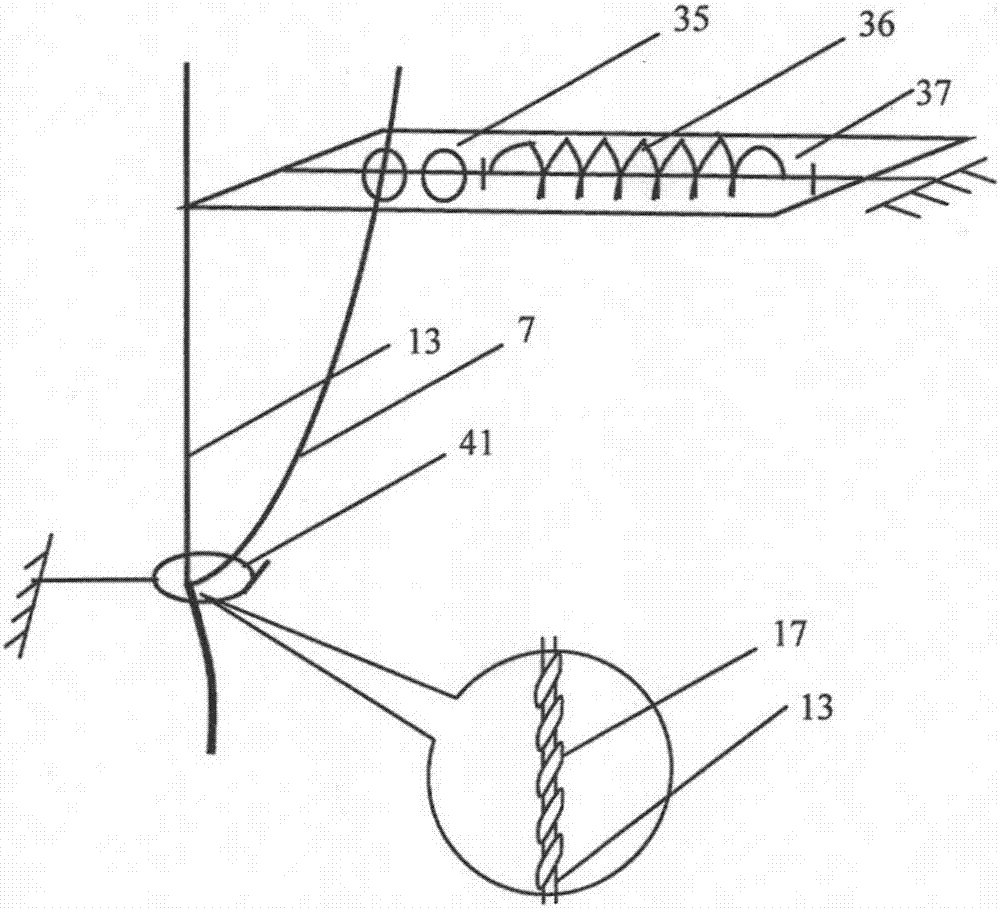

[0041] Example 1 Preparation of spandex / nylon auxetic composite yarn with controllable wrapping angle and uniform structure

[0042] A spinning device and method based on the improved ring spinning auxetic composite yarn with uniform wrapping angle of the present invention is used to prepare spandex / nylon auxetic composite yarn with controllable wrapping angle and uniform structure. Spandex and nylon multifilament are used as core yarn and wrapping yarn, and spandex monofilament bobbin 12 is placed on the roller 11, and spandex monofilament 13 is positively clamped by the first tension clip 14 on the guide bar 19 under the rotation of roller. Feed to the yarn splitter 27 of the drafting mechanism 2; the bobbin 16 of nylon multifilament is suspended on the upper beam 15, and the wrapped yarn 17 is drawn to the wrapped yarn by the second tension clamp 18 on the yarn guide rod 19 The nip of the additional roller 31 of the feeding control mechanism 3A; the spandex monofilament 13 ...

Embodiment 2

[0043] Example 2 Preparation of Spandex / UHMWPE Auxetic Composite Yarn with Controllable Wrapping Angle and Uniform Structure

[0044] Adopt a kind of spinning device and method of the auxetic composite yarn with uniform wrapping angle based on improved ring spinning of the present invention to implement the preparation of spandex / UHMWPE auxetic composite yarn with controllable wrapping angle and uniform structure, Spandex monofilament and ultra-high molecular weight polyethylene multifilament were respectively selected as the core yarn and wrapping yarn, and the rest of the operation steps were the same as those in Example 1, and will not be repeated here. The specific process parameters are shown in Table 1.

Embodiment 3

[0045] Example 3 Preparation of spandex / polyester high-strength yarn auxetic composite yarn with controllable wrapping angle and uniform structure

[0046] Adopt a kind of spinning device and method of the auxetic composite yarn with uniform wrapping angle based on improved ring spinning of the present invention to implement the preparation of spandex / polyester high-strength auxetic composite yarn with controllable wrapping angle and uniform structure. Spandex monofilament and polyester high-strength yarn are used as core yarn and wrapping yarn, and the rest of the operation steps are the same as in Example 1, and will not be repeated here. The specific process parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com