A weaving method for an elastic warm-keeping woven fabric

A woven fabric and elastic technology, applied in the field of functional clothing fabrics, can solve problems such as uneven dyeing, limited application range, and difficult dyeing, and achieve good comfort and novel and unique appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Choose strong 32s / 1 primary color cotton yarn as the warp yarn, 48s / 1 PTT spun yarn, and 42s / 1 cotton colored yarn as the weft yarn, wherein the PTT spun yarn is the inner weft, and the cotton colored yarn is the outer weft.

[0020] (1) Winding the primary color cotton yarn, and warping in batches;

[0021] (2) starch size is used for sizing, the temperature of the size tank is controlled at 92°C, and the speed of the sizing machine is controlled at about 30-50m / min;

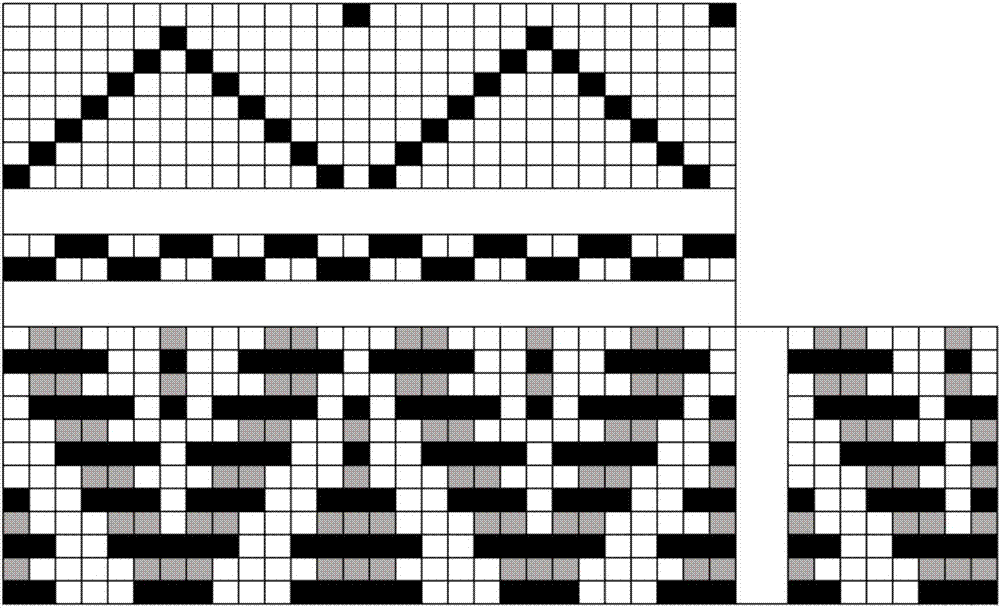

[0022] (3) After sizing, the warp beams are threaded and reeded; according to the machine diagram on the fabric, 8 pages of heald frames are required excluding the selvedge; while the selvage is made of plain weave, two pages of heald frames are required, so a total of 10 pages are required. When drawing in the heald frame, use the straight threading method and thread it according to the picture; because the weft density of the weft double structure is relatively large, the warp density should not be too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com