Portable non-contact digital device for peeping and measuring inner cavity morphology of object

A non-contact, inner-cavity technology, applied in measuring devices, instruments, optical devices, etc., can solve the problems of inability to obtain inner-cavity data, expensive equipment, and inconvenient portability, and achieve high collection efficiency, quick disassembly and assembly, and Portable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

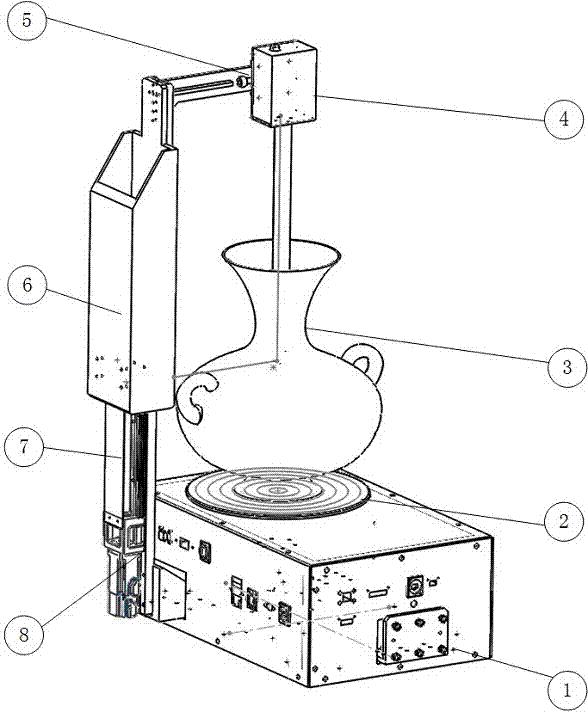

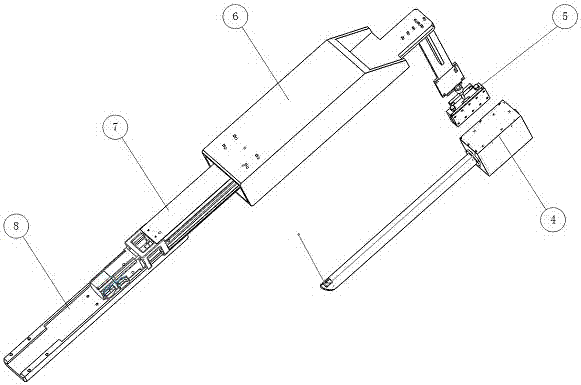

[0032] See figure 1 , The portable non-contact digital device for endoscopic measurement of the inner cavity shape of an object includes an inner cavity acquisition mechanism (4), a control box (1) and a motion support mechanism. It is characterized in that: the inner cavity acquisition mechanism (4) is fixed to one side of the control box through a motion support mechanism to complete the point cloud collection of the inner cavity model of the object under test; the motion support mechanism realizes the movement of the inner cavity acquisition system And support; the inner cavity acquisition mechanism (4) has a mirror and a laser rangefinder, the laser beam of the laser rangefinder is refracted by 90° through the mirror, and the radius value of the inner cavity of the measured object is measured, combined with rotation The angle and the movement value in the up and down direction can be calculated in the host computer to obtain the inner cavity point cloud; the control box (1) ...

Embodiment 2

[0033] The second embodiment, this embodiment is basically the same as the first embodiment, and the special features are:

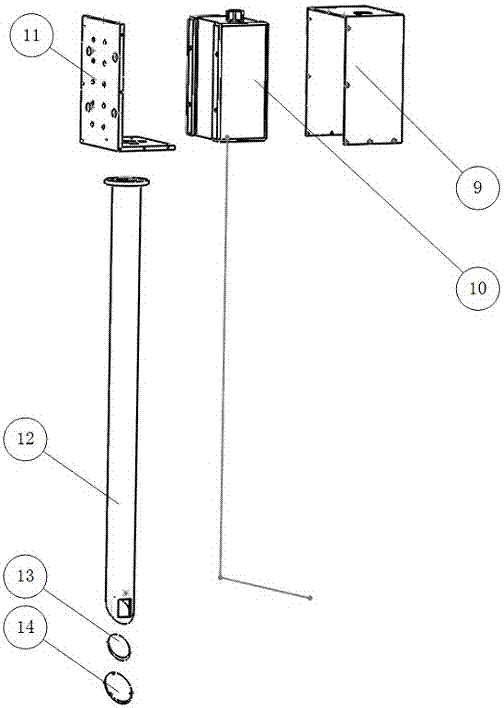

[0034] See Figure 1-Figure 4 The inner cavity acquisition mechanism (4) includes a laser rangefinder (10), an L-shaped laser rangefinder support plate (11), a round tube (12), a mirror (13), and a mirror bottom plate (14) . The laser rangefinder (10) is fixed on the L-shaped laser rangefinder support plate (11), and is used in the laser rangefinder protective cover (9) to measure the distance from the laser emitting point to the cavity; L The support plate (11) of the type laser rangefinder adopts an L-shaped integrated design to ensure the perpendicularity of the laser beam to the horizontal plane and the parallelism of the lower circular tube and the laser beam; the circular tube (12) is fixed on the L-shaped laser rangefinder The lower end of the support plate (11) has a length greater than the depth of the inner cavity of the object to be measured; t...

Embodiment 3

[0038] Such as figure 1 As shown, the portable non-contact type endoscopic measurement digital device for the inner cavity shape of an object includes an inner cavity acquisition mechanism (4), a control box (1) and a motion support mechanism. The inner cavity collection mechanism is fixed on one side of the control box (1) to complete the inner cavity collection work. The inner cavity acquisition mechanism obtains the radius value of the inner cavity through the laser rangefinder (10), and the inner cavity point cloud can be reconstructed by combining the rotation angle and the movement value in the up and down direction. The control box provides power for the motion and laser rangefinder (10) and realizes the control of the motion. The equipment is used for three-dimensional scanning and reconstruction of the internal cavity of an object, so as to further carry out the measurement of the internal cavity of the object, archaeological research and the establishment of a digital...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com