Light intensity-based objective lens positioning method

A positioning method and objective lens technology, applied in the optical field, can solve problems such as positioning error improvement, and achieve the effects of improving positioning accuracy, avoiding errors, and avoiding mechanical complexity operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with embodiment, the present invention is described further, but does not constitute any restriction to the present invention, any limited number of modifications done in the scope of claims of the present invention is still within the scope of claims of the present invention.

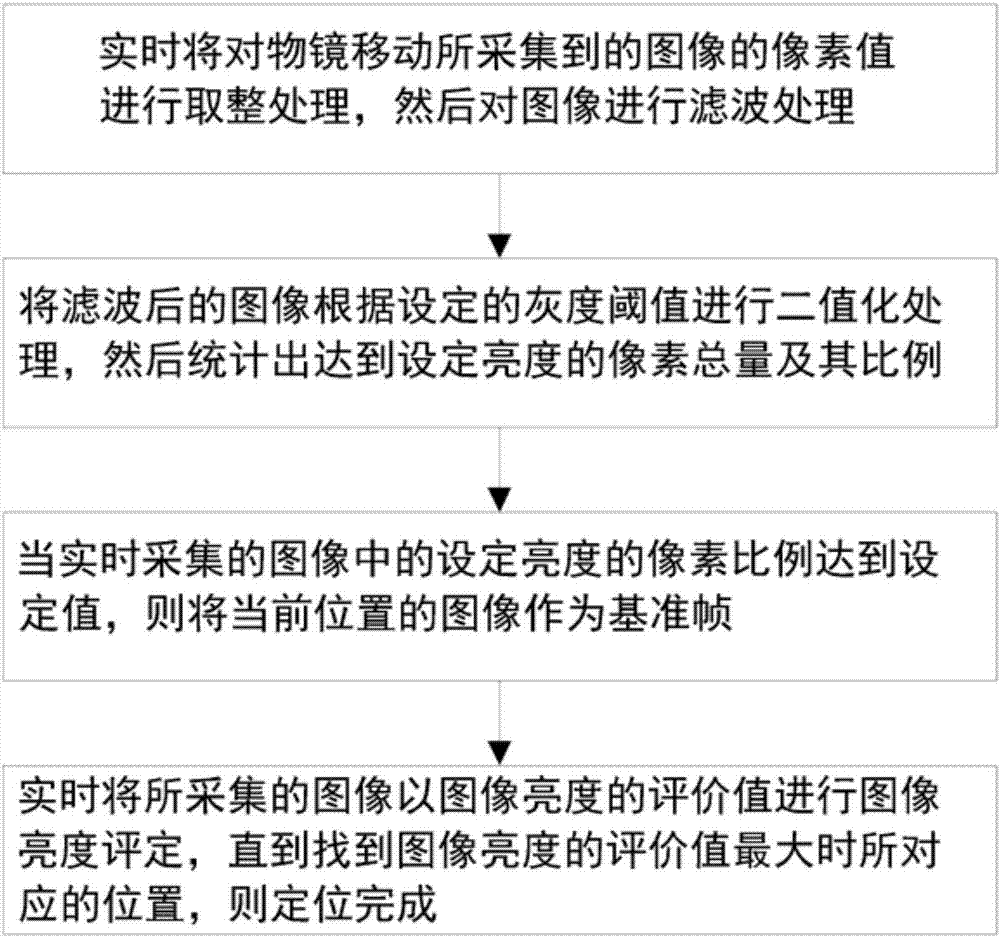

[0046] Such as figure 1 As shown, the invention provides a kind of objective lens positioning method based on light intensity, it is characterized in that, the method comprises following processing steps:

[0047] Step 1: In real time, the pixel value of the image collected by the movement of the objective lens is rounded up, and then the image is filtered;

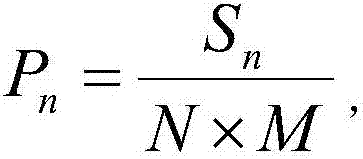

[0048] Step 2: Binarize the filtered image according to the set gray threshold, and then count the total number of pixels reaching the set brightness and their proportion;

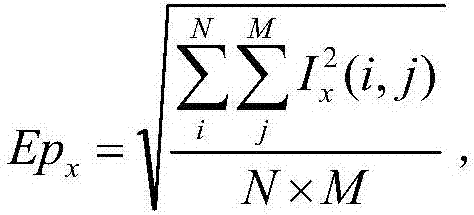

[0049] Step 3: When the pixel ratio of the set brightness in the real-time collected image reaches the set value, the image at the current positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com