A tension-resistant drainage lap ladder

A tension-resistant and side-ladder technology, which is applied in the direction of ladders, buildings, overhead lines/cable equipment, etc., can solve problems such as disconnection of tension-resistant drain wires, line tripping accidents, and hidden dangers of transmission lines, so as to ensure the efficiency of maintenance operations and reduce Maintenance cost, high work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

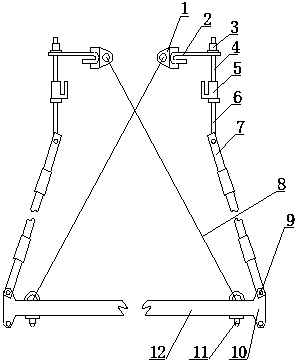

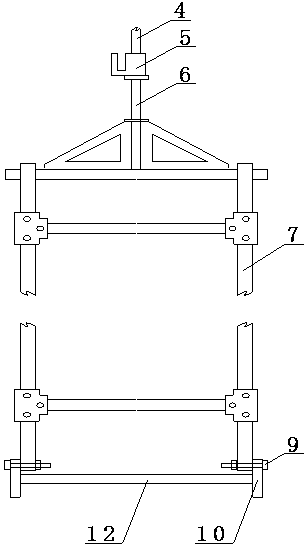

[0011] Embodiment 1, a tension-resistant drainage lap ladder, characterized in that it includes a tower lock regulator (6), a lifting side ladder (7), an X-shaped safety cable (8) and a manned horizontal ladder (12); The structure of the tower lock adjuster (6) is that the middle part of the adjustment screw (4) of the pole tower lock adjuster (6) is provided with a card slot (5), and the top of the adjustment screw (4) passes through the adjustment nut (3 ) is fixed with a hook (2), and the end of the hook (2) is also provided with a hanging ring A (1). The nut (9) is connected with the end tripod (10) of the manned horizontal ladder (12), and the manned horizontal ladder (12) is also provided with a hanging ring B (11), a hanging ring A (1) and a hanging ring B (11 ) is provided with an X-shaped safety pull wire (8).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com