System for utilizing waste heat of low-concentration combustible material in tail gas of Slapple furnace

A Sleep activation furnace and low-concentration technology, which is applied in the field of waste heat utilization of low-concentration combustibles, can solve the problem of not involving supplementary combustion and incineration of low-concentration tail gas combustibles, inability to fully utilize low-concentration combustibles in tail gas, and polluting air energy To achieve the effect of solving the temperature resistance problem of the furnace wall, fully incinerating and utilizing, and reducing pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

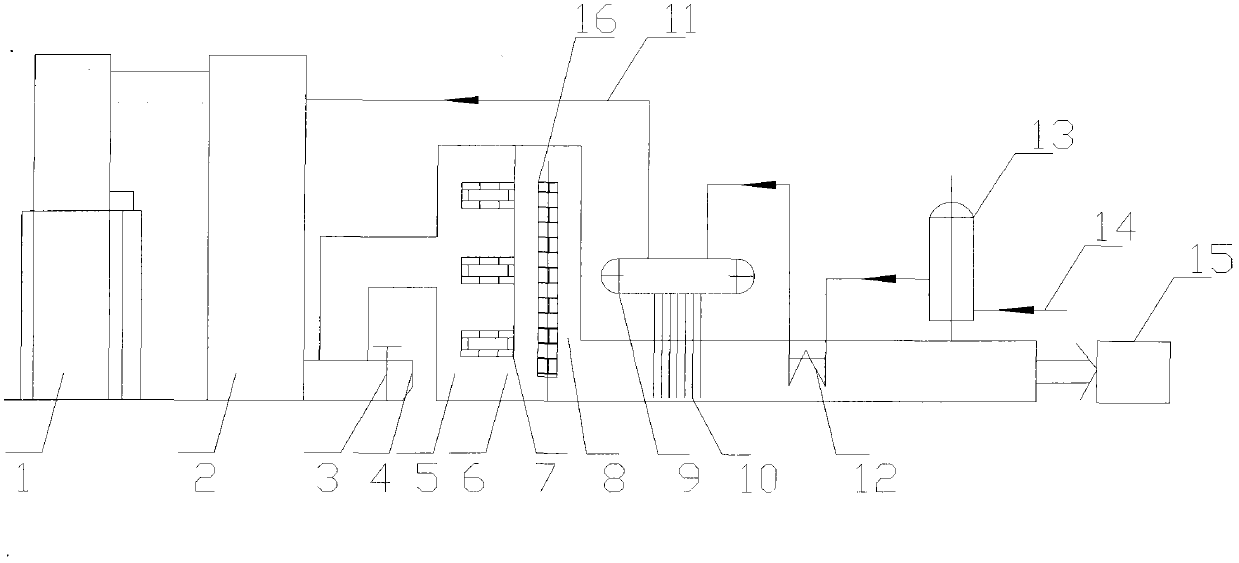

[0008] Below in conjunction with accompanying drawing and embodiment the present invention will be further described (taking 3000kg / d production activated carbon production line as example).

[0009] The original flue 4 at the rear of the regenerator 2 is installed with a flue damper 3, and the tail gas containing low-concentration combustible gas from the regenerator is introduced into the waste heat recovery system. The tail gas first enters the "U"-shaped flue 5, and the tail gas is discharged Inertial separation, the fly ash is deposited and discharged, and then enters the supplementary combustion chamber 6. Multiple air distribution chambers 7 are installed in the supplementary combustion chamber. The height of the air distribution chambers is the same as the distance between the upper and lower drums of the waste heat boiler. windy point. The step of supplementary combustion is to firstly heat the regenerator 16 through auxiliary combustion to make the temperature of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com