Temperature protection device based on ceramic heating plate heating system

A ceramic heating and heating system technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effects of saving production costs, reliable contact, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

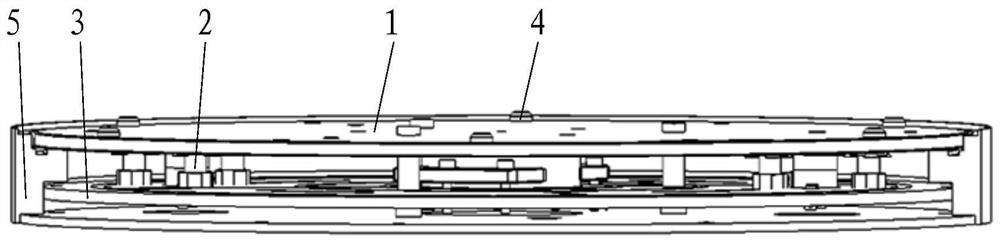

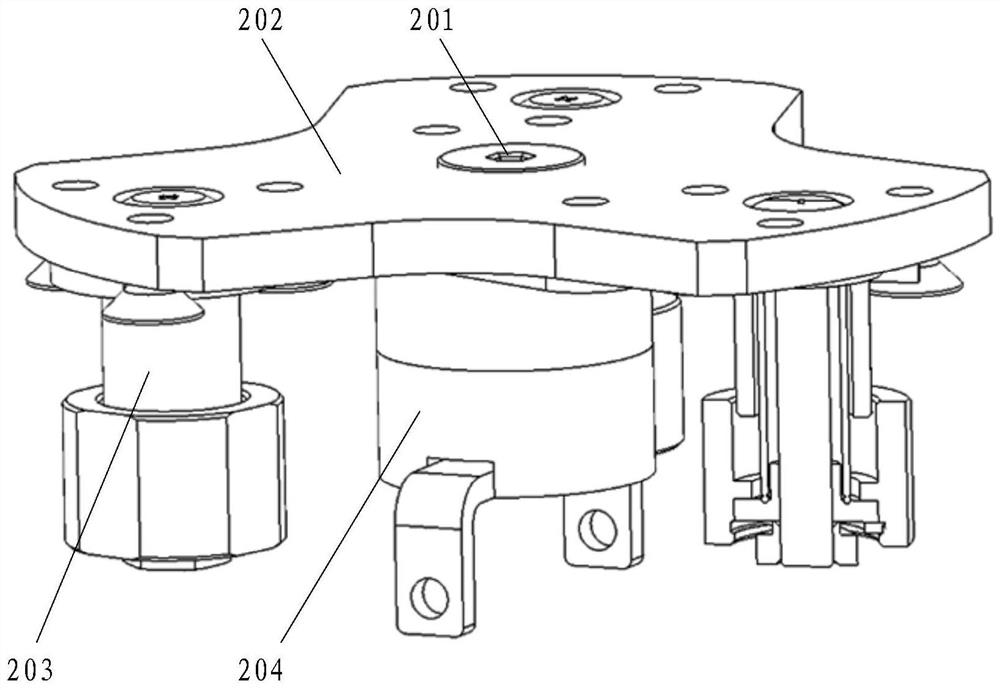

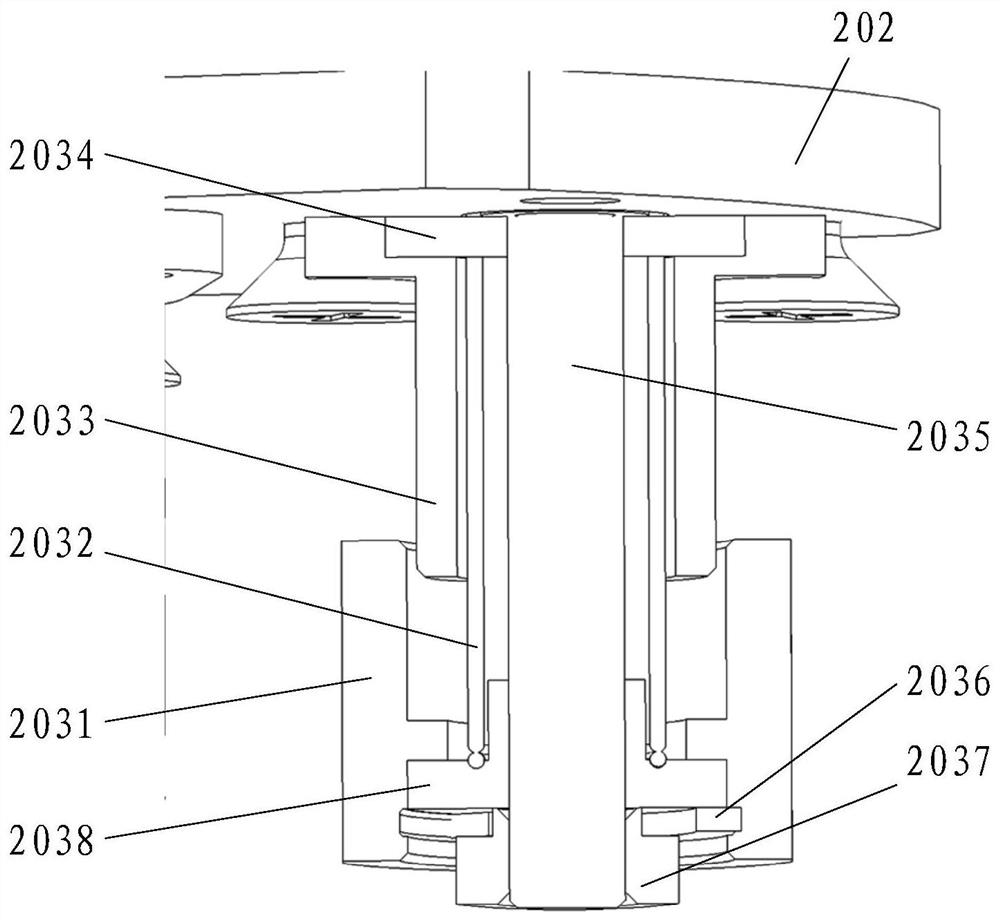

[0023] Such as Figure 1~5 As shown, the present invention includes a ceramic heating plate 1, an elastic contact temperature protection mechanism 2, a sealing plate 3, a wafer positioning guide post 4 and a fixing seat 5, wherein the ceramic heating plate 1 is installed on the upper end of the fixing seat 5, and the ceramic heating plate The edge of the upper surface of 1 is evenly distributed along the circumferential direction with a plurality of (six in this embodiment) wafer positioning guide posts 4 for positioning the incoming wafer; the lower end of the fixing seat 5 is fixed with a sealing plate 3, the An elastic contact temperature protection mechanism 2 corresponding to the heating area of the ceramic heating plate 1 is installed on the sealing plate 3 . The elastic contact temperature protection mechanism 2 includes a temperature switch fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com