au/zno three-dimensional inverse opal heterostructure photocatalyst and its in situ preparation method and application

An anti-opal and heterostructure technology, which is applied in the field of composite nanomaterial photocatalyst preparation and environmental pollutant treatment, can solve the problem of narrow spectral response range of photonic crystal photocatalysts, unsatisfactory carrier separation efficiency, and low photocatalytic degradation efficiency problems such as high activity stability, high degradation rate and mineralization rate, and controllable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

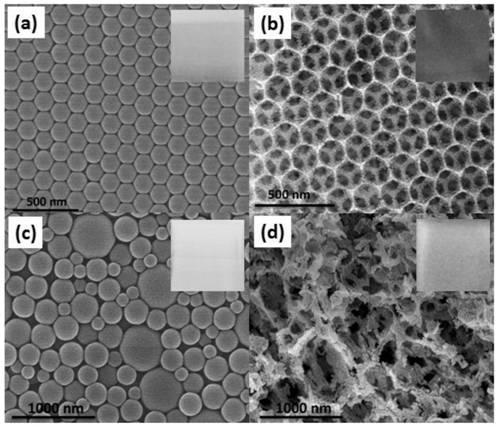

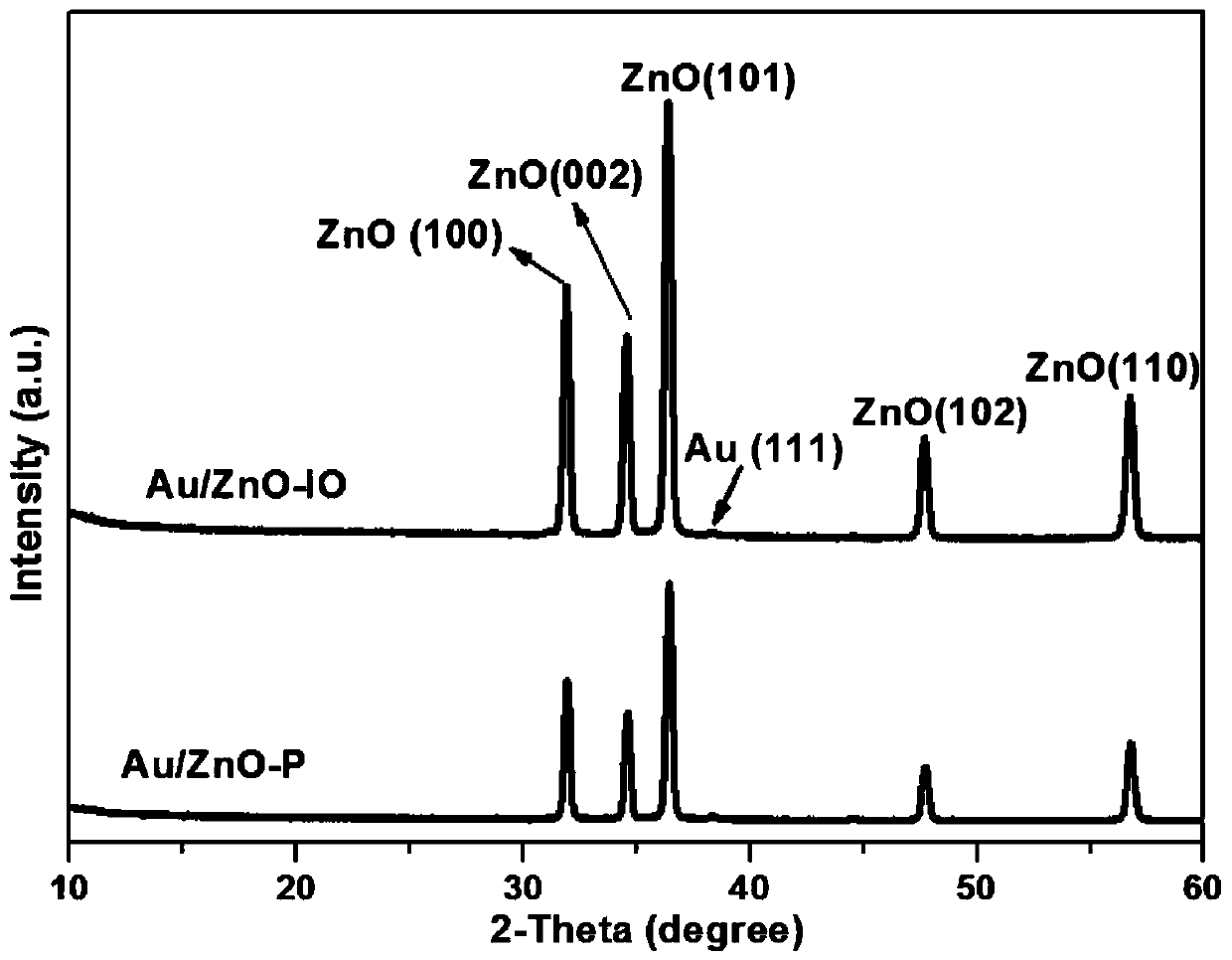

[0029] This embodiment prepares Au / ZnO-IO according to the following steps:

[0030] a. Disperse the surface carboxy-modified PS spheres (PS spheres with a particle size of 180nm) in water to obtain a PS emulsion with a mass percentage of 1.5%; dissolve 3.5g of zinc nitrate and 0.04g of chloroauric acid in 20mL Au / ZnO precursor solution is obtained in a mixed solution composed of water and ethanol at a volume ratio of 3:2;

[0031] b. Clean up, N 2 The dried glass slide was vertically inserted into a 50mL plastic beaker filled with 20mL PS emulsion, and fixed with scotch tape; then placed in an oven at a temperature of 45°C and a humidity of 80% to 90% for 20 hours to obtain opal Structural PS ball template;

[0032] c. Heat-treat the opal-structured PS ball template at 90°C for 30 minutes without wind. After natural cooling, slowly put it into the Au / ZnO precursor solution. After standing still for 120 seconds, take it out slowly and place it flat on the level. On the tabl...

Embodiment 2

[0039] In order to compare with the preparation of Au / ZnO-IO by the in-situ method, ZnO-IO / Au was prepared by a two-step method: ZnO-IO was prepared by the same synthesis steps as the preparation of Au / ZnO-IO (the difference is that no Chlorauric acid), and then Au nanoparticles were loaded on ZnO-IO. The process of loading Au nanoparticles on ZnO-IO is as follows: first put ZnO-IO on the anode tray at the bottom of the magnetron sputtering chamber (the magnetron sputtering instrument used is England, Emitech K550X), vacuumize, and sputter under an argon atmosphere Shoot for 30s to get ZnO-IO / Au.

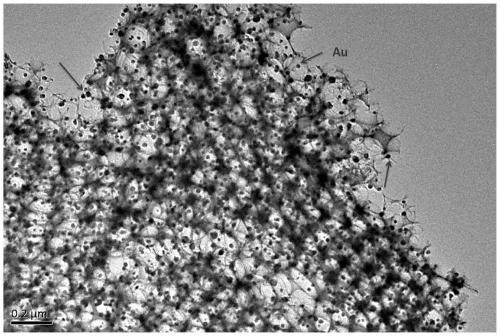

[0040] Figure 4 It is the TEM image of ZnO-IO / Au, from which it can be seen that the small Au nanoparticles are not evenly loaded on the ZnO skeleton, but are loaded on part of the ZnO skeleton in the direction of the arrow in the figure, and within the range of the dotted line There are no small Au particles attached to the ZnO. This is because magnetron sputtering is from top ...

Embodiment 3

[0042] In order to compare with Au / ZnO, the preparation process of ZnO is the same as in Example 1, except that there is no PS ball on the glass slide and no chloroauric acid in the precursor solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com