Metal board positioning assembly

A technology of sheet metal and positioning components, applied in positioning devices, metal processing equipment, feeding devices, etc., can solve problems such as high cost, inability to adapt, and affect production efficiency, and achieve high automation efficiency and precise positioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

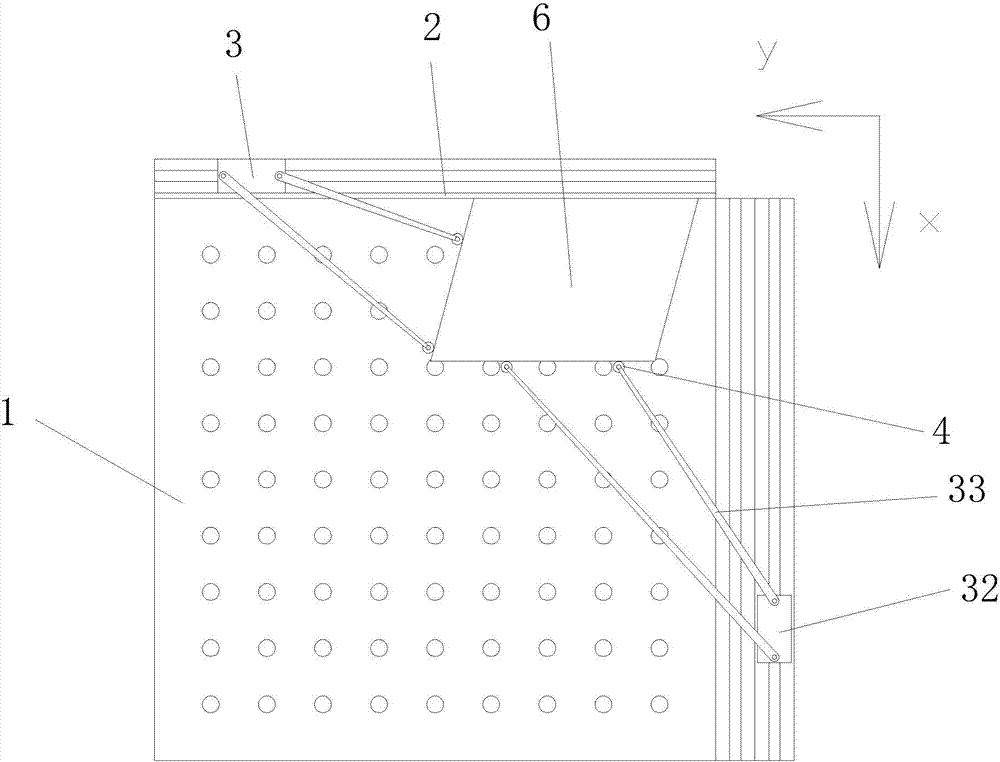

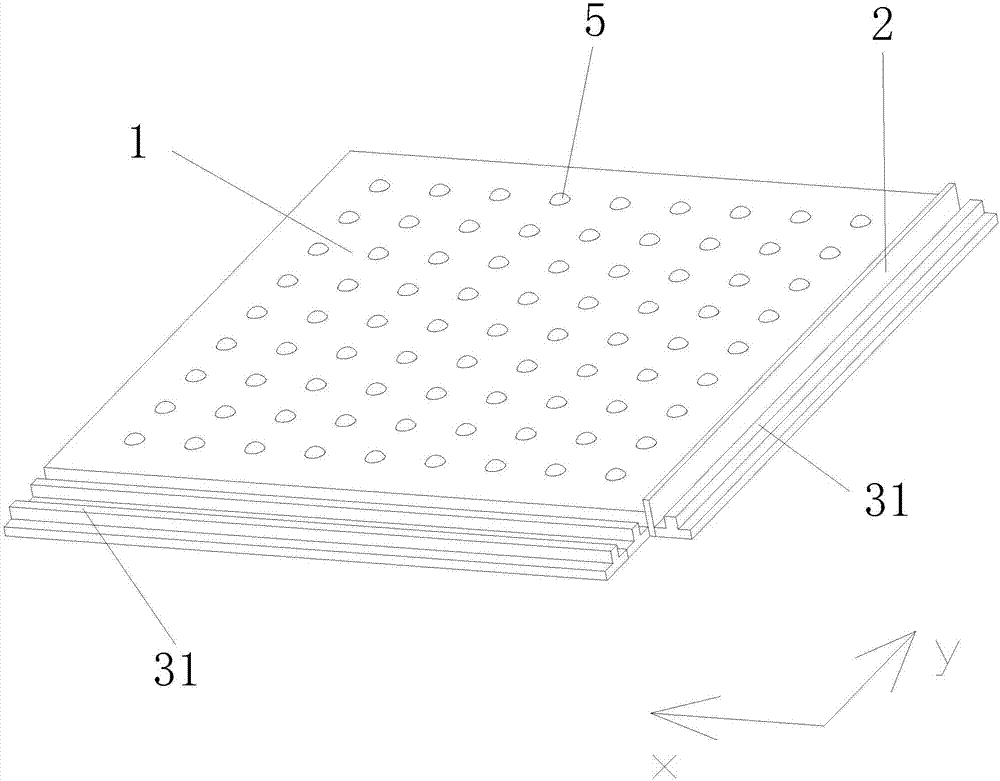

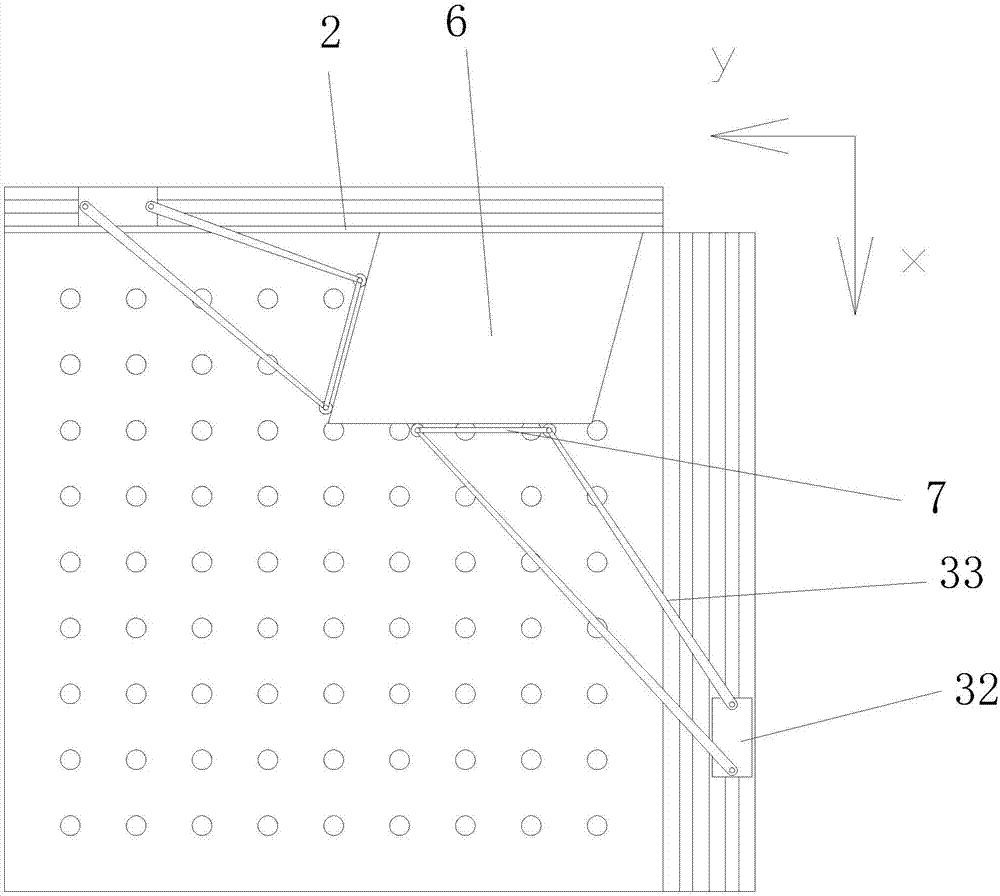

[0019] The present invention as Figure 1-3 As shown, it includes a workbench 1, a positioning rib 2 and a pair of positioning mechanisms 3. A pair of positioning mechanisms 3 are respectively arranged on both sides of the workbench at right angles, and form the X-direction and Y-direction positioning of the metal sheet 6,

[0020] The positioning rib 2 is perpendicular to the workbench and arranged along the right-angled side of the positioning mechanism in the Y direction on the workbench, and the positioning rib is located on the inside of the positioning mechanism in the Y direction;

[0021] Described positioning mechanism comprises guide rail 31, drive block 32 and a pair of electric push rod 33, and described drive block 32 is slidably connected on the described guide rail 31, and one end of a pair of electric push rod 33 is hinged on described drive block 32, The other end is hingedly provided with roller 4.

[0022] The positioning mechanism slides through the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com